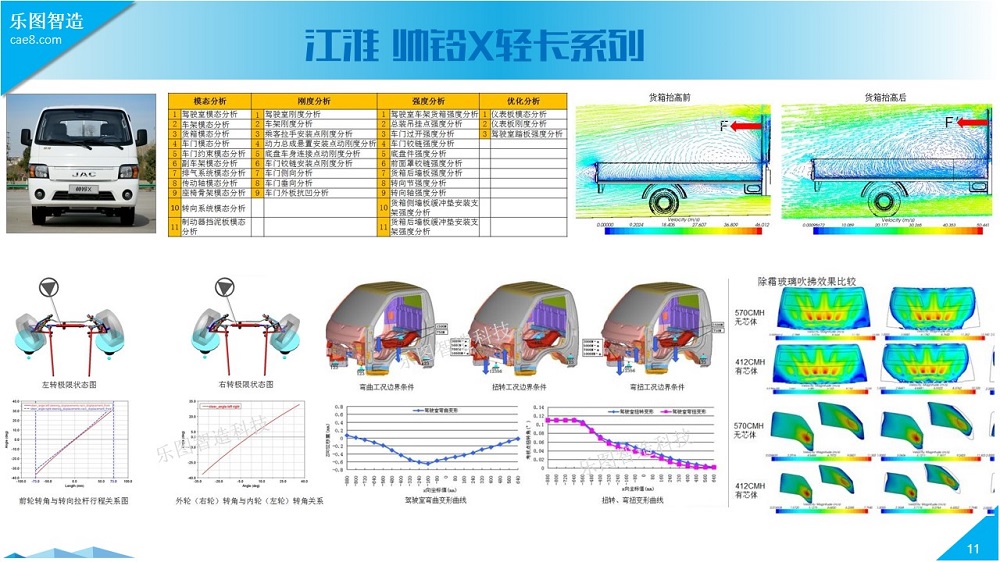

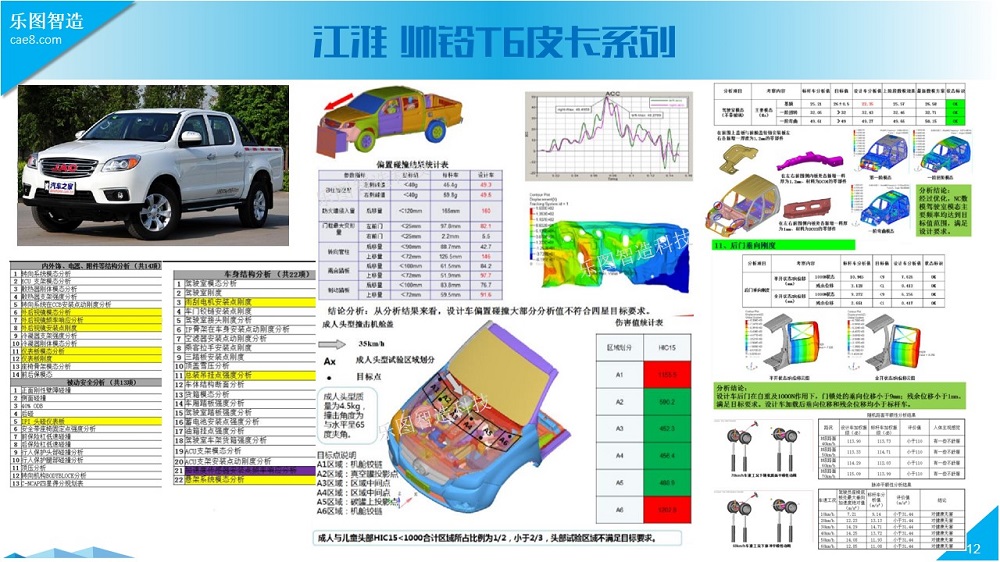

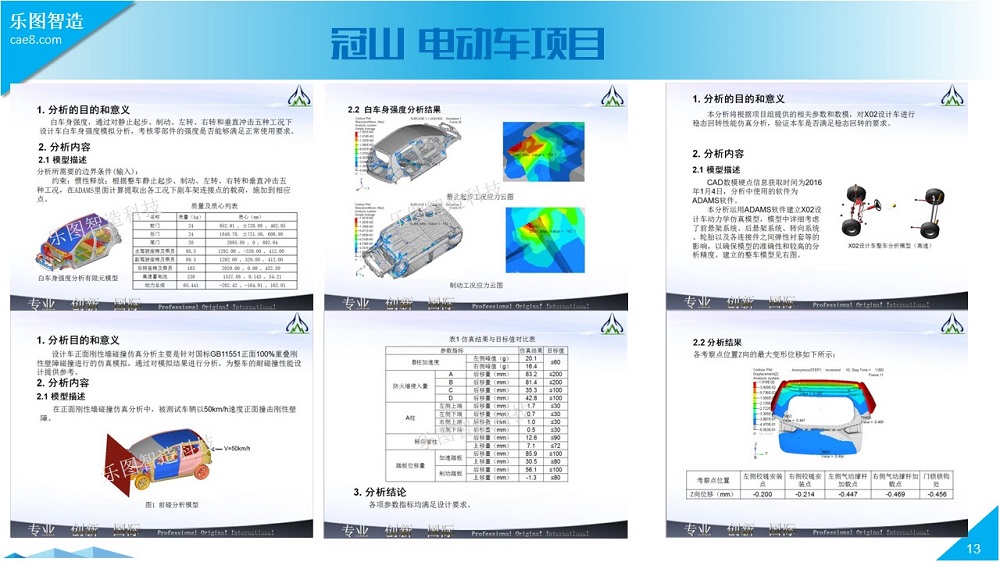

Industry case

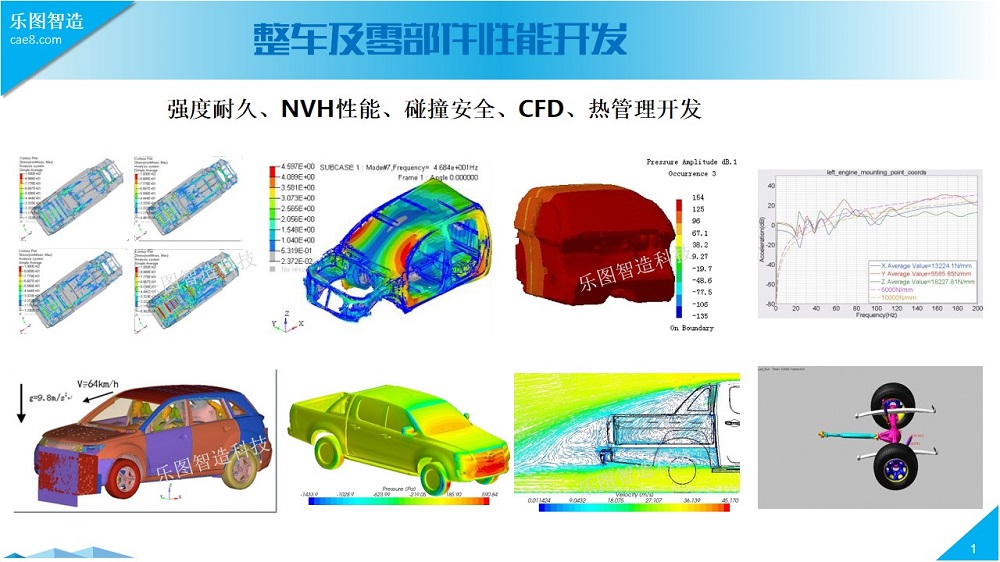

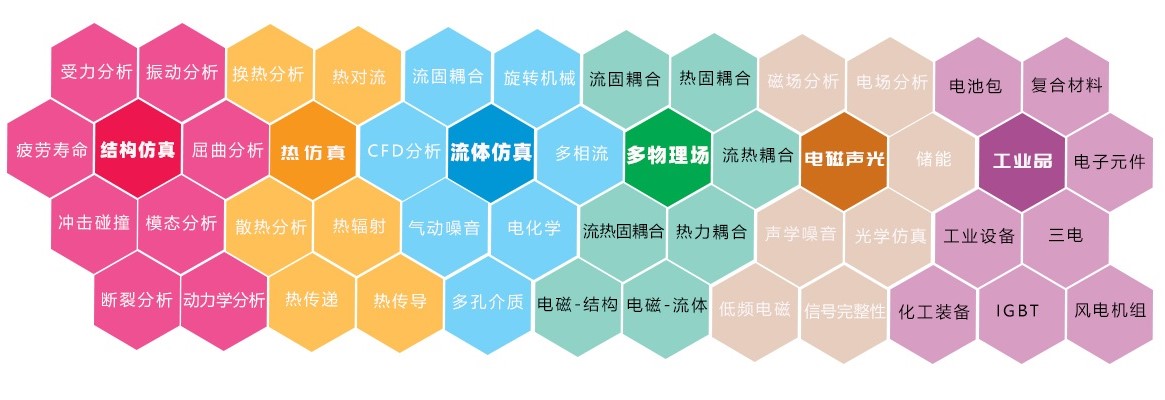

We provide services such as strength durability, crash safety, NVH performance development, and research and development of internal combustion engines, turbochargers, torque converters, automotive brakes, exhaust systems, motors, batteries, lights, bearings, fuel tanks, and CAE analysis and simulation.

Provide customers with rich automotive finite element simulation services

It includes project undertaking, software and hardware selection and configuration, industry-customized secondary development, professional technical training, personnel training, fixed-point technical support, etc., aiming to maximize the benefits of customers' investment.

Get to know the backbone of the team

Diversified service types

Special consulting services such as CAE engineering simulation consulting, enterprise simulation software selection and product provision, high-performance simulation hardware construction, industry-customized development and platform construction. And it has accumulated rich simulation consulting experience and typical cases in the industry, providing customers with project-based simulation consulting and comprehensive solutions for the service industry.

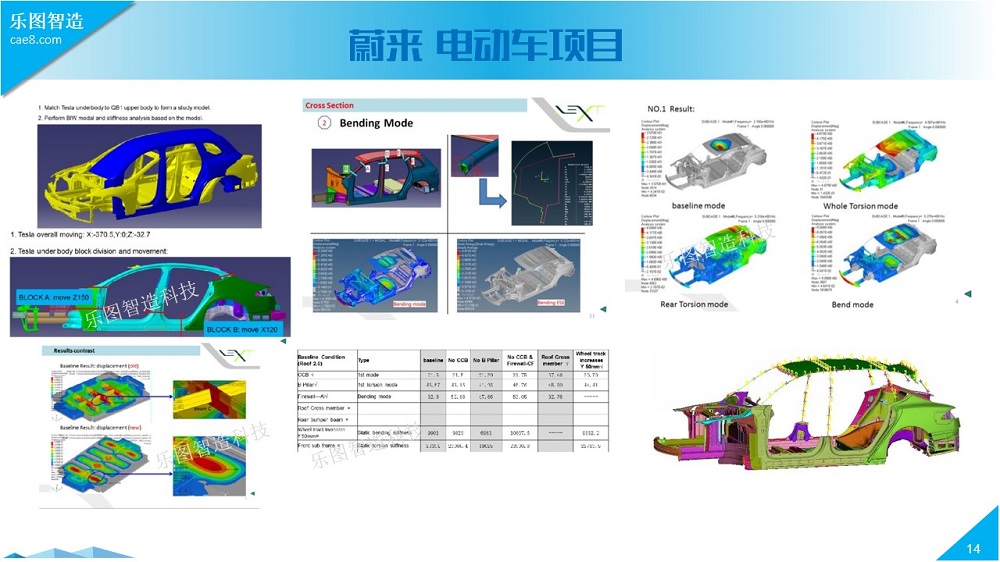

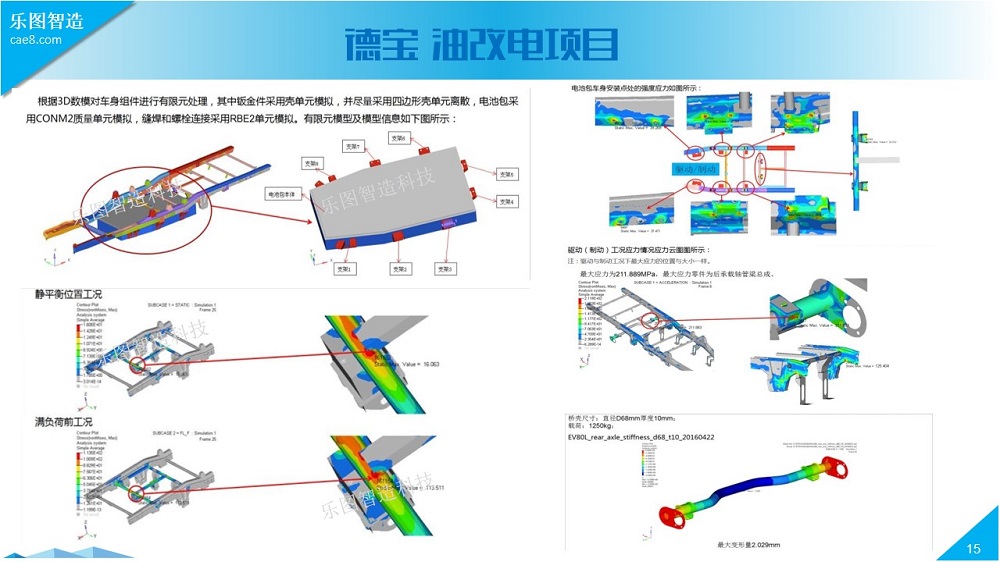

Practical experience in finite element simulation in the automotive industry

The automotive industry is one of the most important industries in the world at present and also one of the most competitive industries. An automobile, as a complex product composed of thousands of parts, needs to solve a large number of engineering problems to achieve the R&D goals required by modern society. With the increasing maturity of modern CAE simulation technology, enterprises can combine this advanced R&D means with traditional testing and design experience to form a complementary relationship, thereby enhancing the R&D and design capabilities, effectively guiding the R&D and design of new products, saving product development costs, shortening the development cycle, and thus greatly improving the market competitiveness of enterprises.

In the modern automotive design process, CAE analysis plays a very important role. The highly competitive automotive market has put forward high requirements for the development cycle, quality and performance of automobiles. The role of CAE lies in that it can drive lean design and rapid automotive development processes and can save a lot of development costs and shorten the development cycle.

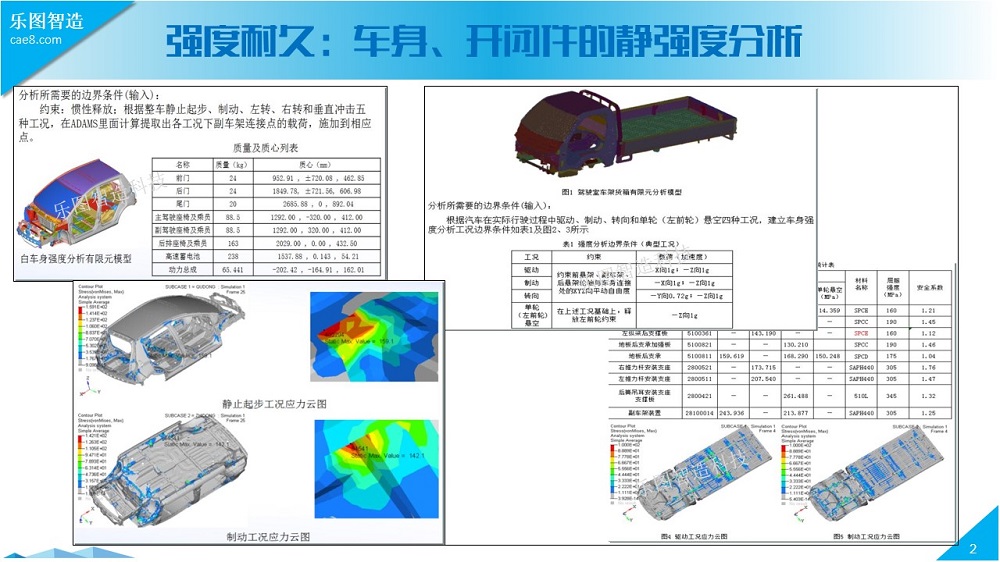

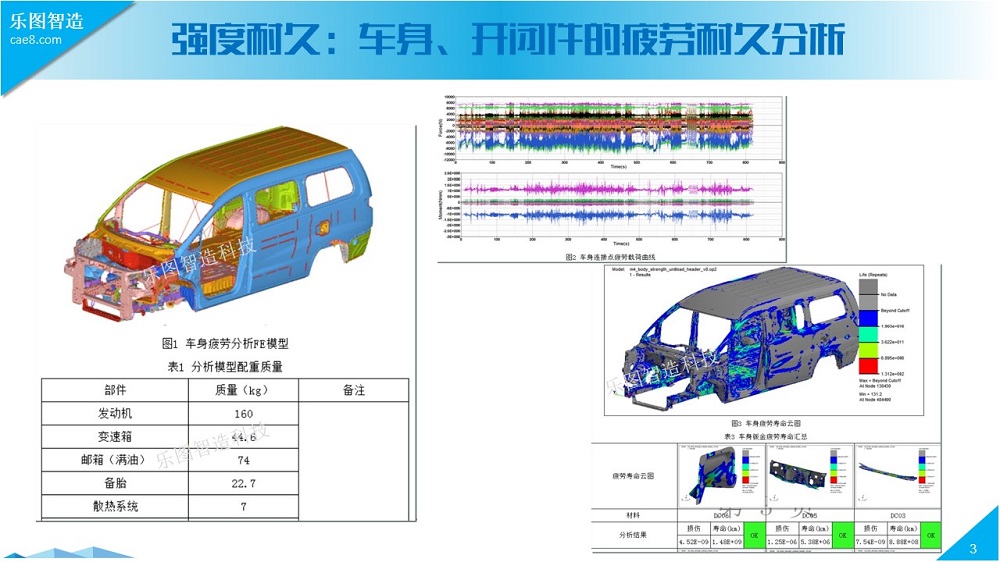

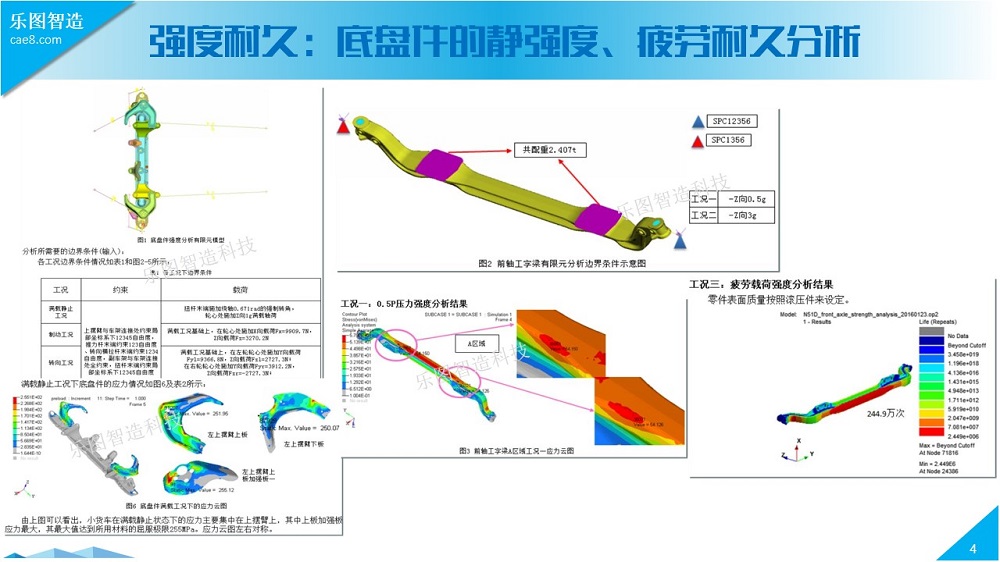

Vehicle durability analysis

☑️ Vehicle durability analysis modeling ☑️ Body strength and stiffness analysis ☑️ Door strength and stiffness analysis ☑️ Interior and exterior trim strength and stiffness analysis

☑️ Other closure strength and stiffness analysis ☑️ Fatigue durability analysis ☑️ Suspension strength and stiffness analysis

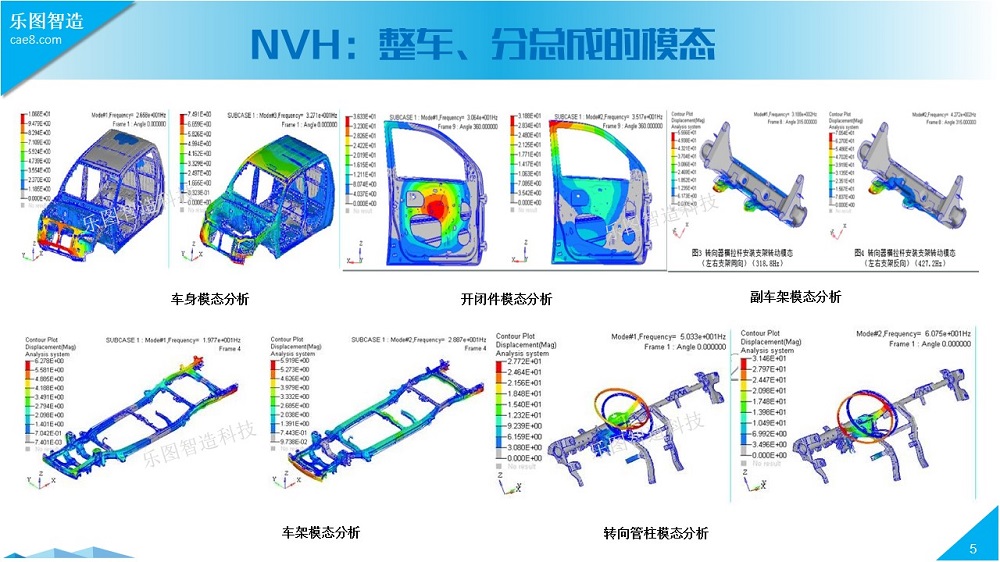

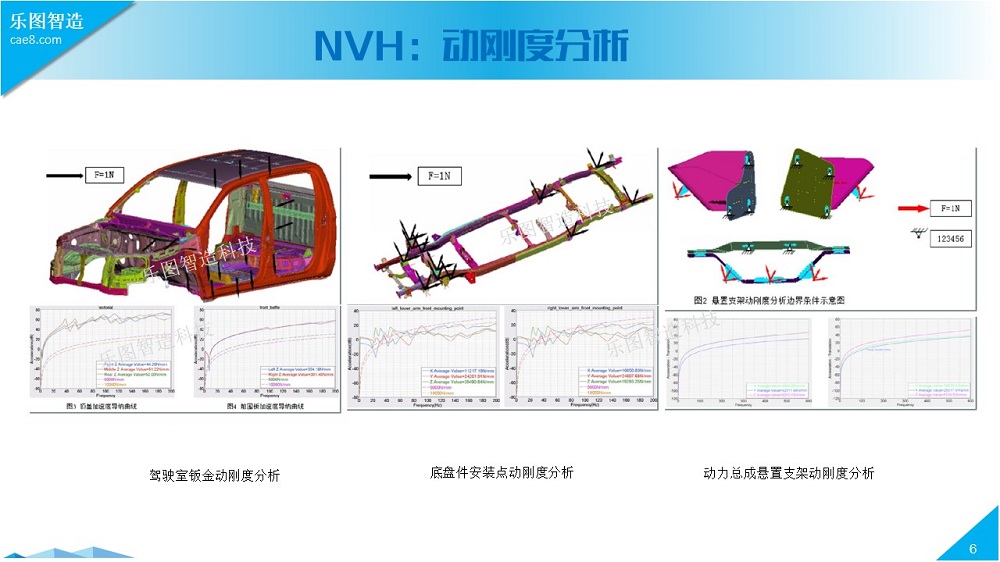

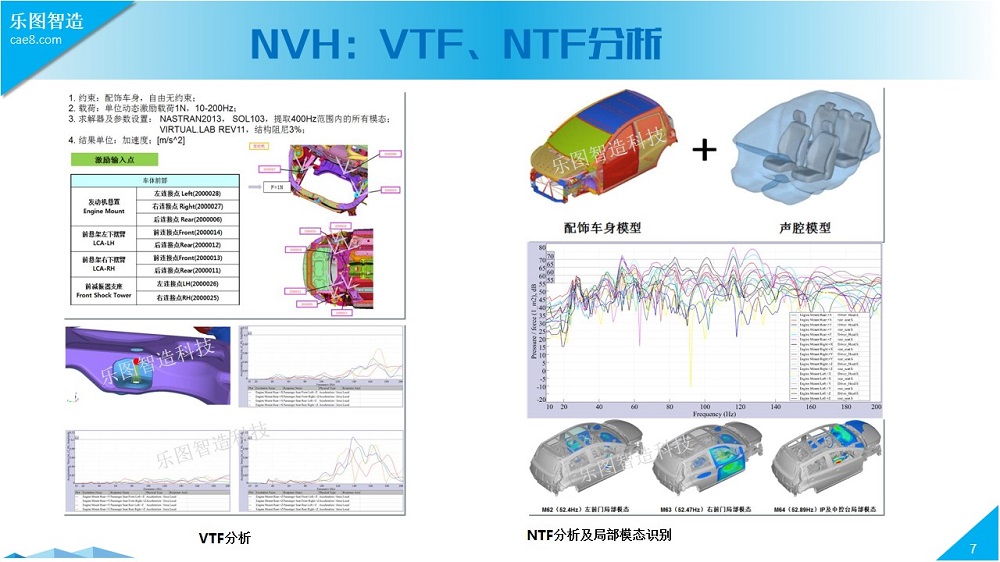

Vehicle NVH performance analysis

☑️ Body and accessory NVH analysis ☑️ Component NVH analysis ☑️ Whole vehicle low-frequency NVH analysis

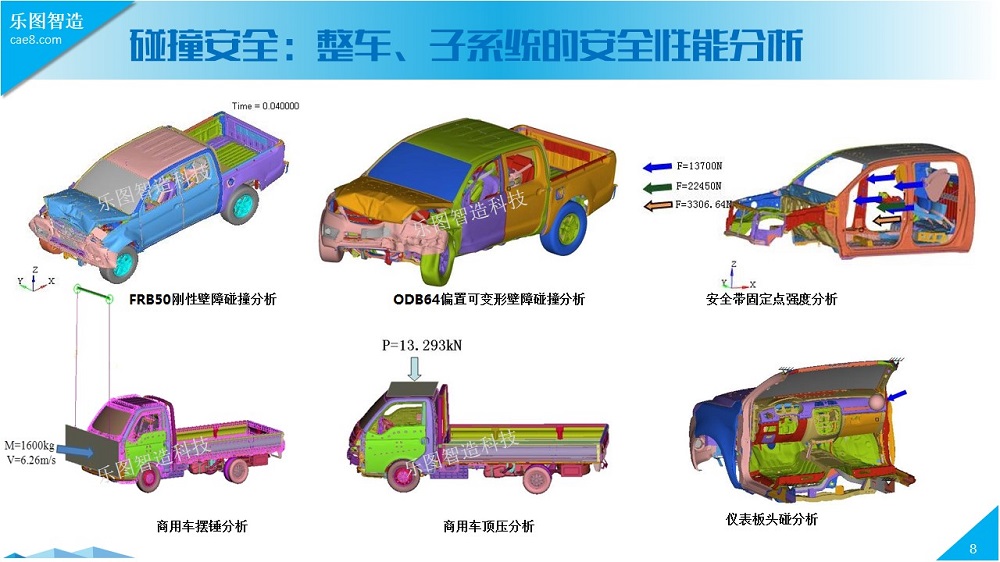

Crash safety performance analysis

☑️ C-NCAP 100% frontal impact ☑️ C-NCAP 40% offset collision ☑️ C-NCAP side impact analysis ☑️ Rear-end collision analysis ☑️ Pedestrian protection analysis

☑️ Luggage displacement and occupant protection device performance analysis ☑️ Seat and seat belt mounting and fixing point strength analysis (FMVSS 207/210) ☑️ Interior head impact (FMVSS 201)

☑️ Front and rear bumper collision analysis ☑️ Occupant restraint system matching and optimization (frontal, offset, side) ☑️ Side door impact strength analysis (FMVSS 214) ☑️ Roof crush analysis (FMVSS 216)

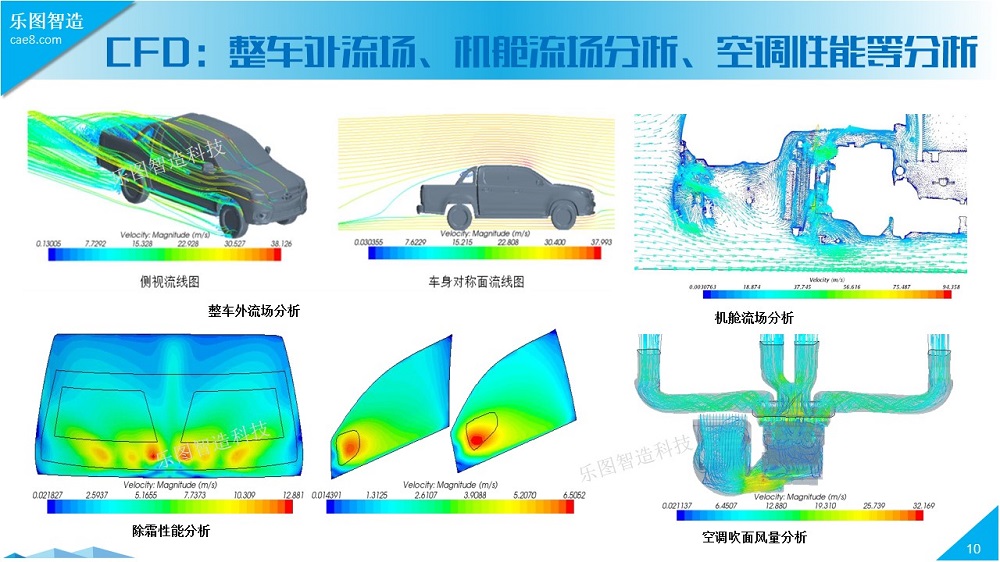

CFD and aeroacoustic analysis

☑️ CFD analysis of the whole vehicle external flow field ☑️ CFD analysis of the air conditioning system ☑️ Whole vehicle thermal management analysis ☑️ Whole vehicle aerodynamic noise analysis

Many project implementation experience cases

Letu Finite Element has unique advantages in the following aspects

Professional technical consulting team

The company gathers global industrial product experts and simulation technology experts. All experts have more than ten years of engineering simulation experience, a profound industry background, a solid professional theoretical foundation and proficient software application skills, and can effectively and professionally solve the actual engineering problems of customers. The company's consulting experts are distributed across the country, and they have a strong ability to provide localized support for customer needs.

Rich technical resources

It includes the strong support of senior technical experts from foreign partners such as CADFEM and ANSYS companies, as well as the inheritance and development of their CAE simulation knowledge and experience, and is able to provide world-class technical capabilities and engineering experience.

Rich CAE/CAD simulation tools and R&D tool resources with a wide range of specialties

Including FEA, CFD, FSI, Multiphysics, MDO, multi-domain system simulation, etc., which can jointly solve various complex simulation problems.

Declaration: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

View More Cases: Heat Dissipation Analysis Thermal Simulation Analysis Collision Analysis Modal Analysis CFD Analysis Electromagnetic Field Simulation Analysis Drop Analysis Fatigue Analysis

I guess you may have the following questions right now:

- What can you do? How much does it cost?

- How long will it take? What do I need to do?

- What information needs to be provided?

- How was it After sale?

It is difficult to have a standard answer to the same question because everyone has different emphasis. Please fill in the form information or directly online contact, we will give you the most appropriate answer!