Service item

Provide FEA finite element analysis consulting services, for you to solve the difficult recruitment software cost problem

Provide FEA finite element analysis consulting services, for you to solve the difficult recruitment software cost problem

Rich experience in finite element simulation projects, involving automotive machinery, electronics, petrochemical, civil, construction, biomedical and other industries

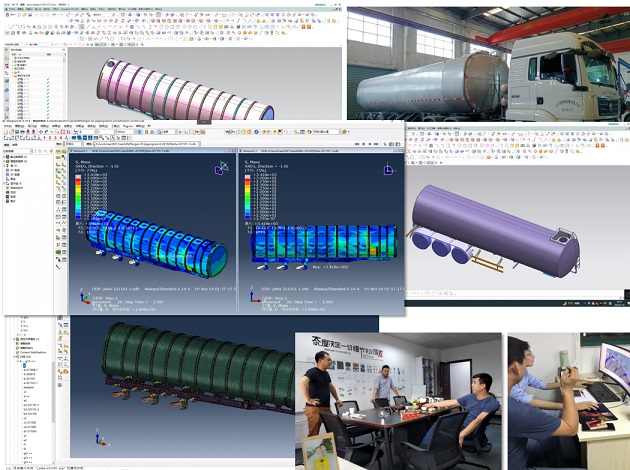

Henry Transportation Co., Ltd. is a transportation company, deeply aware of the importance of lightweight tank truck and stability, the lower the failure rate for the transportation company, the more controllable the cost and delivery time, therefore, Henry decided to customize the tank truck, for various reasons, the existing market car companies can not meet his requirements, so, A bold decision was born to build our own car. In 2015, we found our company Lotto intelligent creation. After in-depth communication, we hit it off immediately. Based on their deep understanding and demand of their own industry, we provided the effect information they needed. The vehicle strength finite element simulation analysis verification and optimization, after 2 years of day and night efforts, after repeated debugging finally in 2017 will finally finalize the design, followed by the investment of hundreds of millions of related processing and assembly equipment, the end of 2017 the first lightweight tank truck successfully hit the road, the vehicle weight reduction of 10%. Stability failure rate reduced by 50%. After 2 years of on-the-road data, followed by the development of a second upgrade in 2019, it took 3 years to successfully develop an all-aluminum beam tank truck in 2022, and the weight of the vehicle was reduced by 30% on the basis of the first generation.

The main difficulty of this project is that the vehicle design scheme should not only meet the requirements of strength, insulation, safety and stability, but also reduce the weight of the vehicle as much as possible. The preliminary finite element simulation analysis, verification and optimization are crucial, and the theoretical simulation combined with experimental testing reduces the cost and improves the efficiency.

View More cases

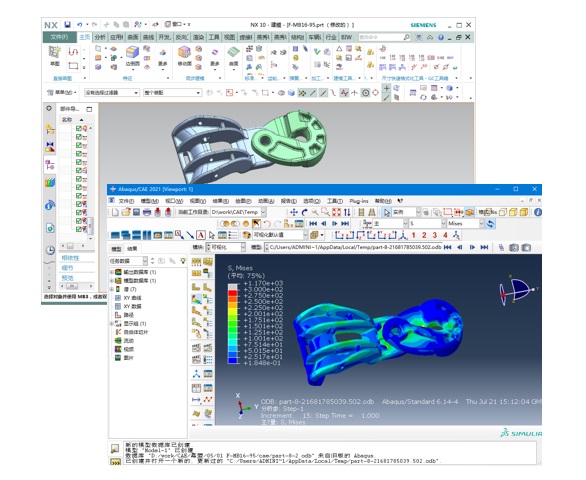

A plastic product for power equipment in 2021, from product optimization design →cae analysis and verification → template processing → mold flow analysis and mold design → mold manufacturing → small batch production, our company provides a one-stop solution, and the product successfully reduces the weight by 15%. Under the background of the international economic situation, the competition is becoming more and more fierce, there are many companies trying to save manufacturing costs, of which lightweight is an effective direction, on the basis of meeting the functions of the product, reduce the weight of the product, so that it can save a very considerable product material cost.

In product design and development, finite element simulation analysis and verification, mold design and manufacturing, injection molding production one-stop solution, convenient for customers and enhance competitiveness.

View More cases

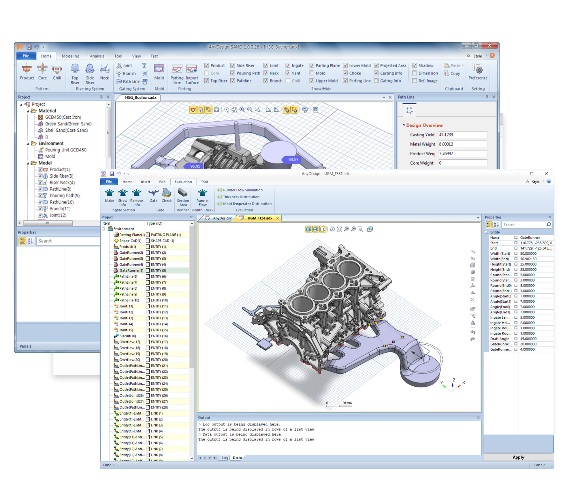

Nanjing Yunhai Light Metal Co., Ltd. is a listed company engaged in the sales of non-ferrous light metal materials and the research and development and manufacturing of metal products. The company has a professional finite element analysis team, but there are often some difficult finite element analysis tasks that they cannot complete. After their comprehensive evaluation on professionalism, service quality and cost performance, they choose to cooperate with Lotto intelligent creation Technology. Since 2013, the cooperation has been more than ten years. The cooperation between the two parties on finite element analysis is very pleasant and the tacit understanding is very high.

also added our company to the supplier system of its subsidiaries, and some of the next level of Yunhai suppliers designated finite element analysis service agencies.

View More casesIt is difficult to have a standard answer to the same question because everyone has different emphasis; Please fill in the form information or directly online contact, we will give you the most appropriate answer!