Industry case

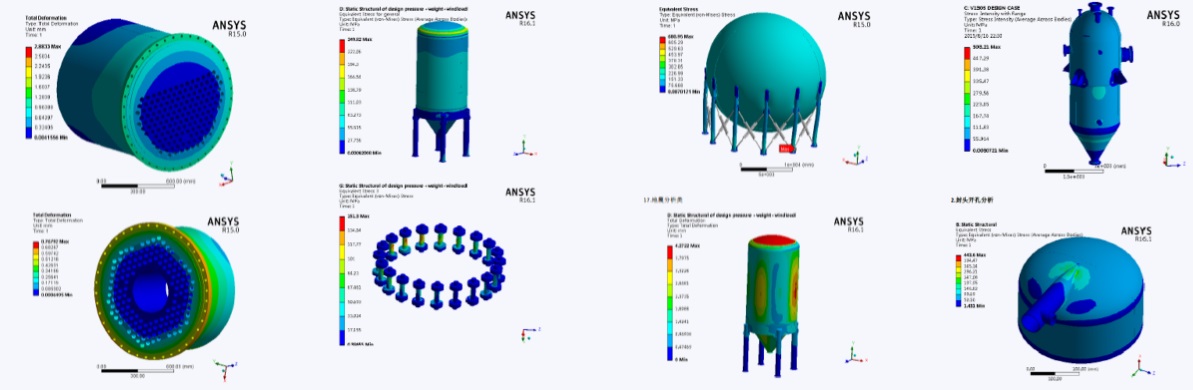

Provide finite element analysis and calculation of petrochemical industry, such as pressure vessel stress analysis, geological engineering, drilling engineering, oil production engineering, storage and transportation engineering, refining and chemical engineering, offshore engineering, petroleum and petrochemical equipment finite element analysis and simulation solutions. Pressure vessel stress analysis design SAD certificate qualification.

Finite element calculation for petrochemical industry

The company can design fixed pressure vessel rules, mobile pressure vessel rules and stress analysis design (SAD qualification certificate), and can provide complete design drawings, calculation books and stress analysis reports in line with relevant standards, the standard range covers Chinese standards, ASME, EN, JIS and so on. Executive standard: JB4732, ASME Ⅲ, ASME Ⅷ-1, ASME Ⅷ-2, EN13445 Russian standard OCTP52857.1 ~ 12-2007 can be analyzed and designed for different failure modes of equipment at all levels according to the implemented standards.

Undertake the stress analysis of all kinds of pressure vessels in the petrochemical industry, buried pipe strength, flange, gate valve strength, snapping fast opening thermal stress, wellhead tree strength, derrick bearing capacity, bag dust collector efficiency, single-arm ring strength, dust adsorption and discharge, pumping unit dynamics, container fatigue Stress analysis project of equipment, nozzle, spherical tank, heat exchanger, tower, hydrogenation reactor, etc. The stress analysis report issued by our company can pass the strict review of ABS, BV, DNV, CCS and other institutions to help enterprises successfully pass the qualification certification.

Understand the team backbone

The company has a strong technical research and development team, 2 doctors, 5 masters, 4 senior title technical personnel, for the machinery industry, energy field, chemical industry, mechanical and electrical industry, medical industry in the manufacturing plant to provide high quality and efficient technical support and services, and to assist in solving difficult problems in engineering.

Pressure vessel stress analysis (Pressure vessel SAD Analysis Design Certificate)

In recent years, with the improvement of software and hardware environment, finite element analysis has been gradually introduced into the pressure vessel industry, and has achieved a lot of results. Stress analysis plays a key role in the design of nozzle, spherical tank, heat exchanger, tower, hydrogenation reactor and other equipment. After China's entry into WTO, the project general contracting is more and more widely accepted by domestic enterprises. Many domestic enterprises have also adopted the method of general contracting to undertake many domestic and foreign large-scale project design tasks. Almost all foreign-related projects without exception require ASME ASmi standard finite element analysis capabilities. With the contact between domestic and foreign enterprises and the diversity and closeness of cooperation, it is believed that the application of finite element analysis in the domestic pressure vessel industry will be more popular. Make full use of finite element simulation as a tool to design products with higher technical content, safer and more economical.

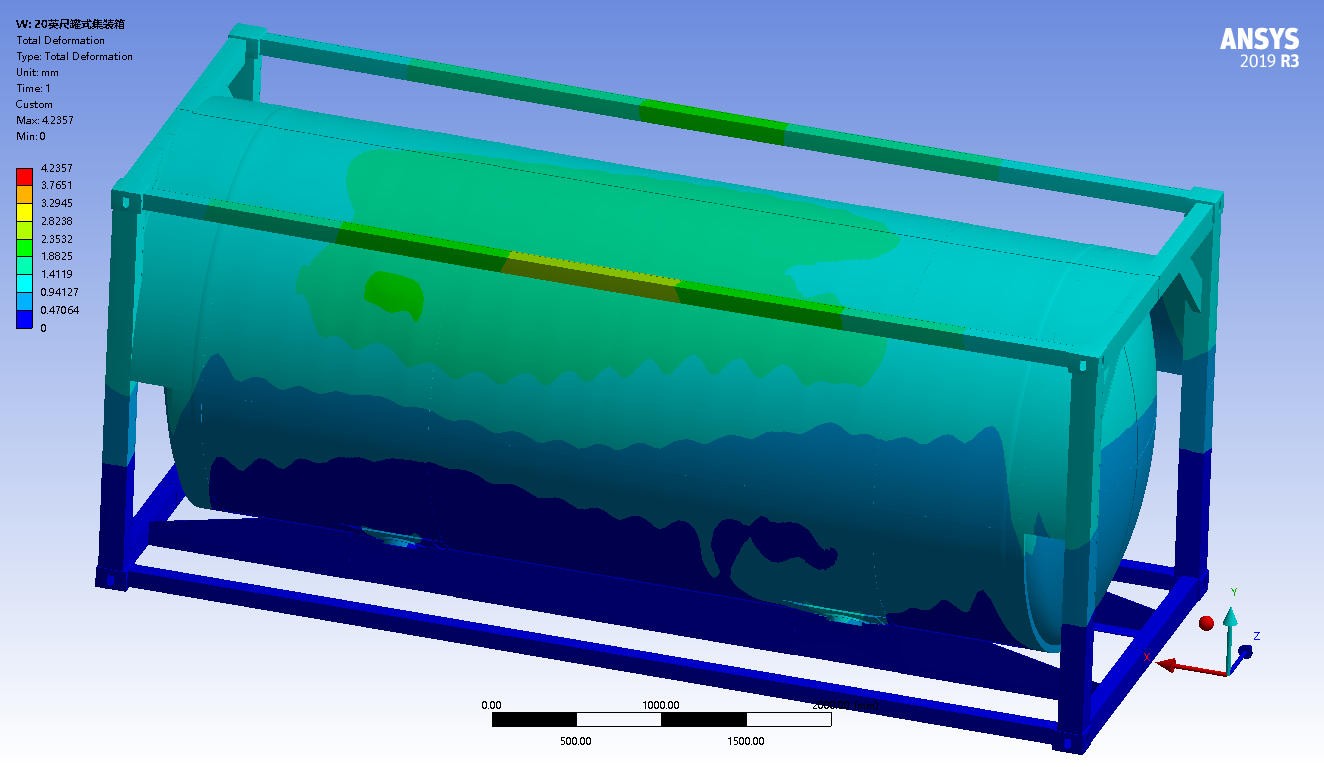

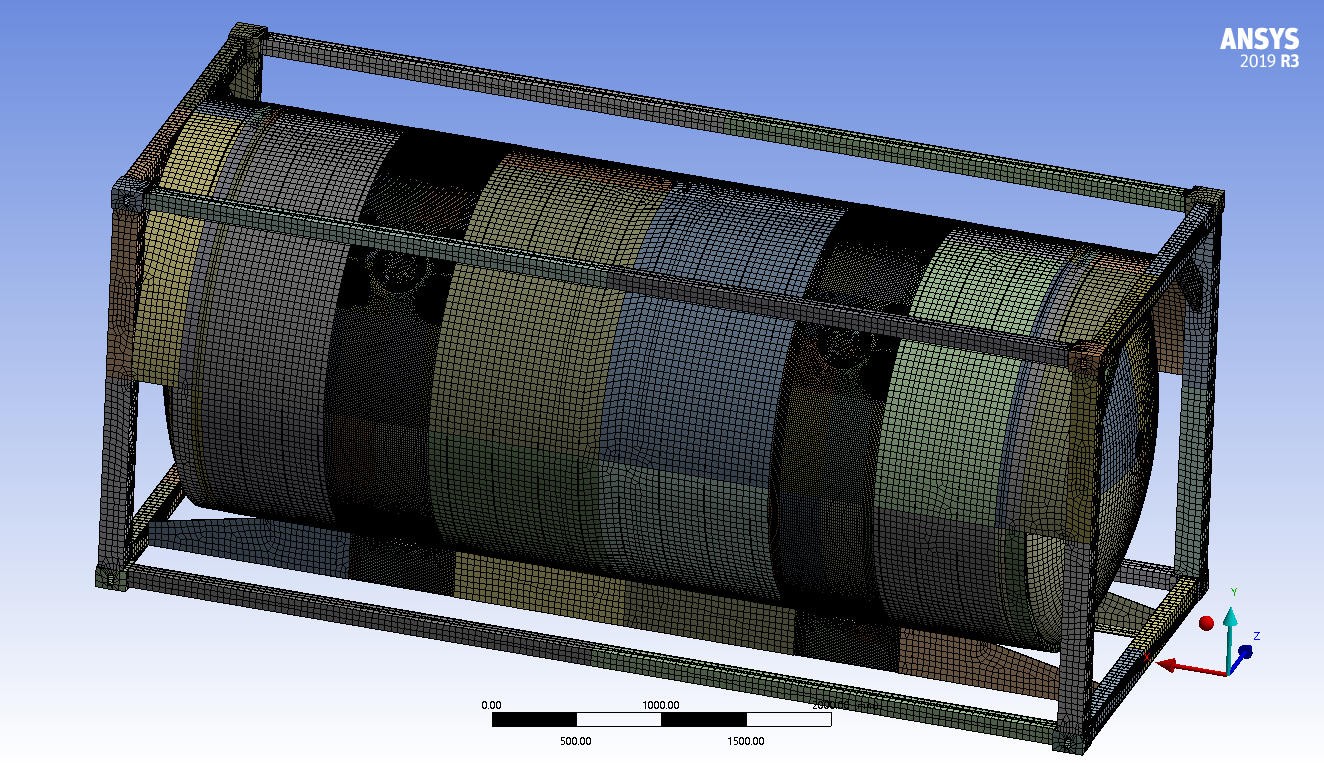

Case 1: Tank container pressure vessel

ASME Asmi standard pressure vessel stress analysis, internationally, the design level of this industry is generally higher than the level of our country, the reasons are many. As a designer, we should ensure the economy of the design as much as possible under the premise of ensuring the safety of the equipment. Foreign enterprises have more and more applied the analysis and design method of the limit load to the analysis and design of the container. The practice of foreign enterprises is: from the preliminary design before the tender to the detailed design after the final bid, the finite element analysis is widely used as a tool for analysis and design. The preliminary design before bidding involves the cost and the bid value. Therefore, the preliminary analysis of the preliminary design is also very important. Preliminary design also requires the analyst to complete the preliminary analysis in a short time, which requires the design engineer's analysis and design ability to be relatively high. In the detailed design stage after winning the bid, the application of finite element method is more important and extensive. All these have greatly promoted the improvement of the finite element analysis level in foreign petrochemical industry. Most of the domestic enterprises on the application of finite element is still limited to the "check calculation", rather than from the beginning of the preliminary design to the final detailed design throughout.

Stress analysis design assessment for different failure modes of all levels of equipment according to ASME Section III, Section I, Section NB or Section VIII, Section II Pressure vessel analysis design. Specific scope includes:

1. Stress analysis of each working condition of the equipment (design, operation, abnormal, crisis, accident condition, test) corresponding to the primary stress assessment of different stress limits;

2. Stress analysis of equipment operating conditions (or operation plus abnormal conditions) one time plus two times stress (stability) assessment;

3. Equipment low cycle/high cycle fatigue assessment; Fracture assessment, other assessments such as: stability (buckling) under working conditions, thermal ratchet, three-way stress assessment;

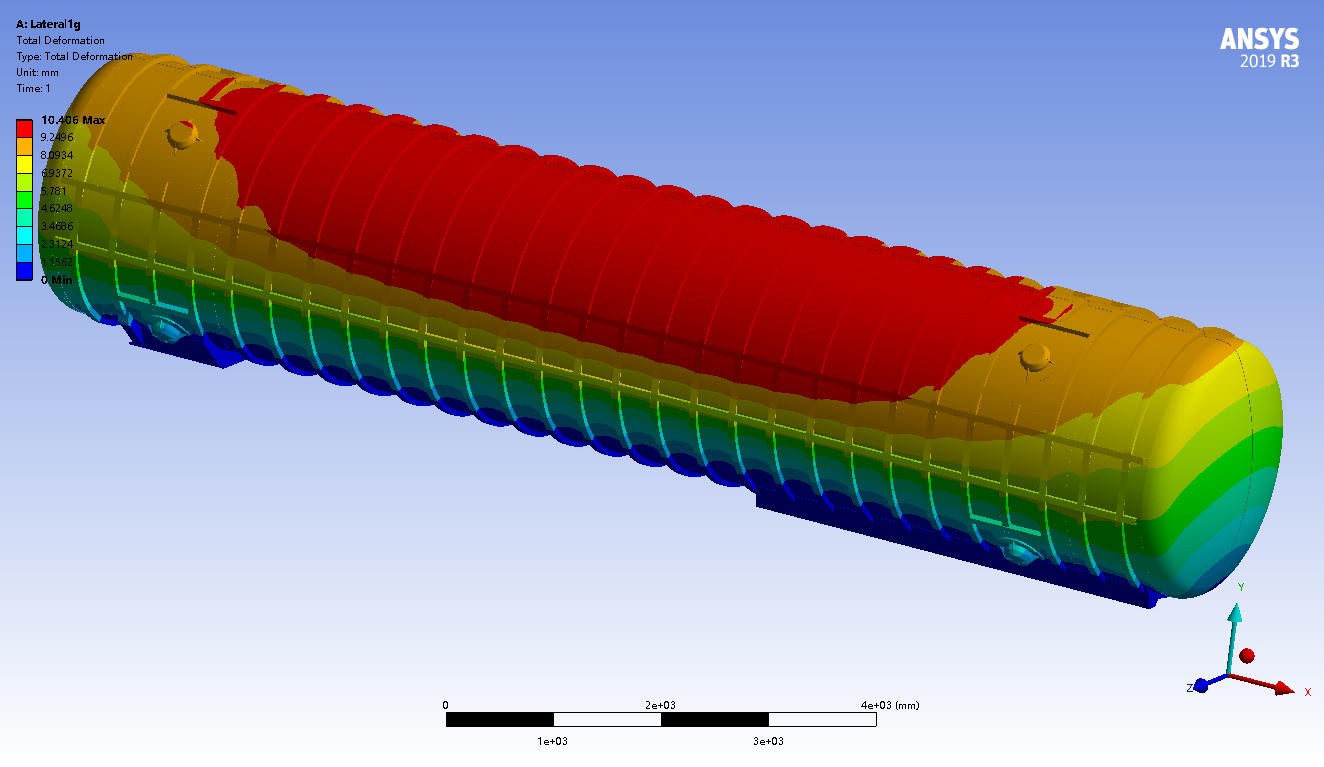

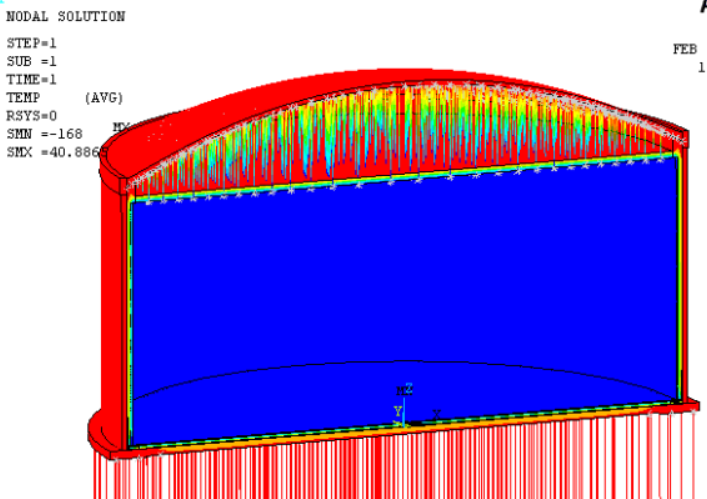

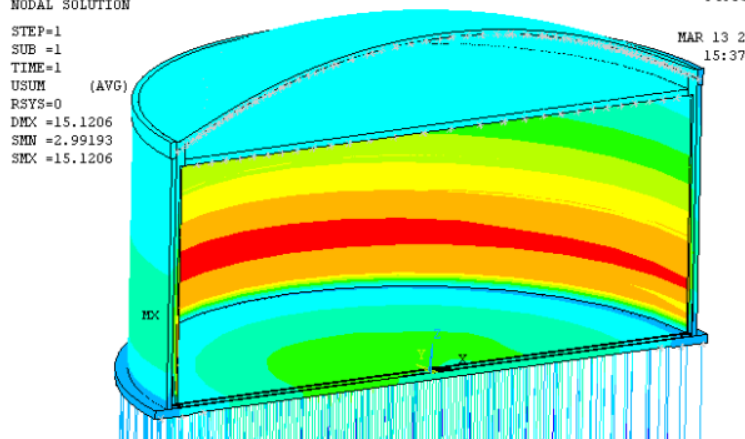

Case 2: LNG double-deck cryogenic road tanker (left picture), Marine fuel storage tank (right picture)

With the domestic participation in the bidding of international projects, the use of finite element analysis as a modern tool to assist our design in the preliminary design and final product design will become a new highlight of the industry. To join the competition in the international market, domestic enterprises will change the old road of design by experience in the past, and pursue greater profits in the economy, so that engineers will put the real time and energy on the design and innovation of equipment. Pressure vessel stress analysis limit load analysis means will also shine, making the design of pressure vessels more safe, more economical, more efficient. It is also necessary to make full use of the "design optimization function" that finite element software already has, so that our design catches up with and exceeds the international level.

2.6 cubic LNG double-decker cryogenic highway tank truck is designed in accordance with the specification "NBT47058-2017 refrigerated liquefied gas truck tank". The load considered: internal and external pressure, tank car weight, medium weight, longitudinal and vertical impact load, etc. The finite element analysis report passed the strict examination of the supervision and inspection authority.

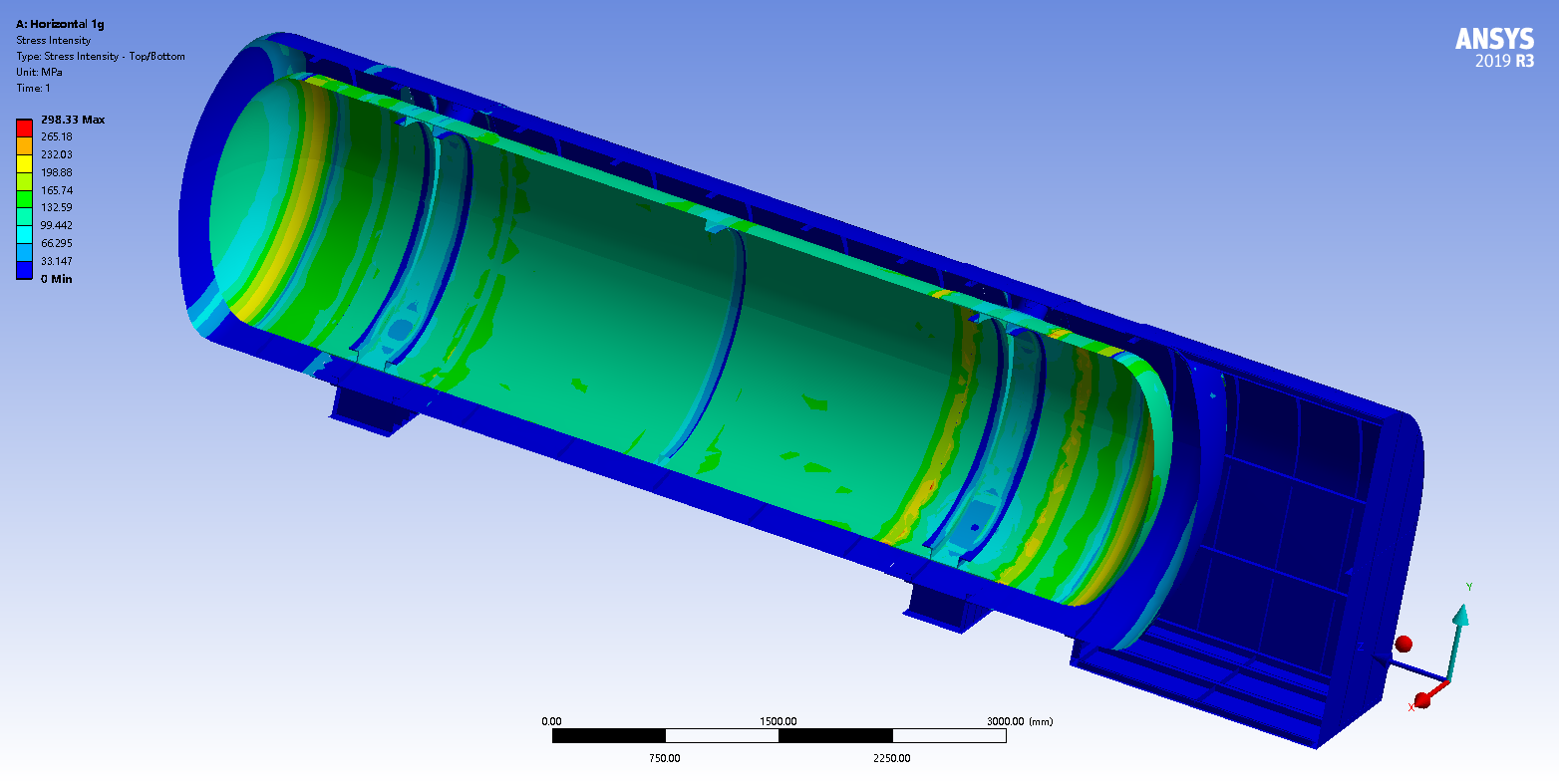

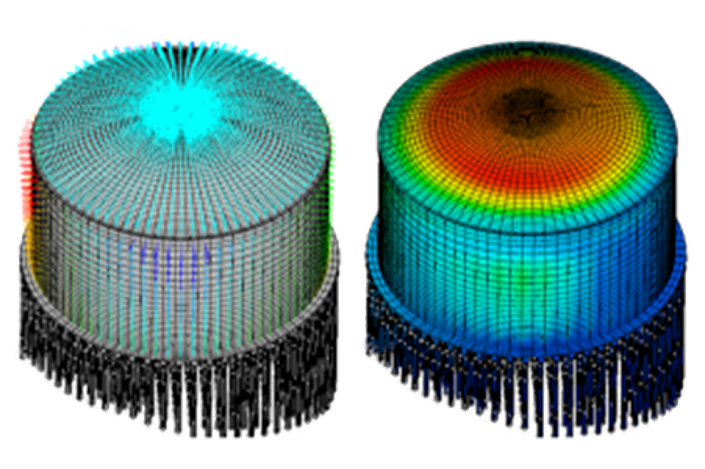

Case 2: Finite element simulation of a large full-capacity LNG storage tank

With the increasing demand for liquefied natural gas, the development trend of LNG storage tanks is large and complicated. The current capacity of full-capacity storage tanks has reached more than 200,000 square meters, the space size is close to 100 meters, and the structure is complex. The response of the whole tank and important parts of a large full-capacity LNG storage tank under various complex load combinations was analyzed, and the tank design was optimized to ensure the reliability of the storage tank under various working conditions. The engineer passed the SAD certificate of pressure vessel analysis and design.

The definition and calculation of load conditions based on specifications for design requirements. Can consider temperature field, prestress, dead load, live load, wind load, snow load, LNG hydraulic pressure, design positive and negative pressure, pressure test, water pressure test, leakage, earthquake, explosion, impact, fire and other conditions, static, dynamic, stability calculation. SLS(Applicability Limit State) and ULS(Final Limit state) load combination and evaluation are carried out according to the specifications and design requirements.

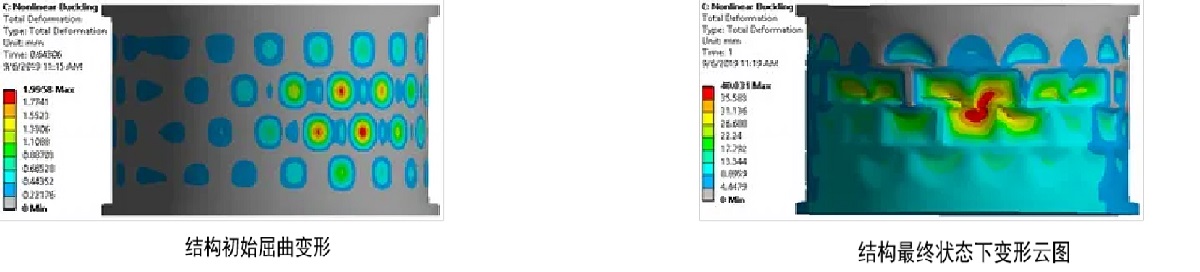

Case 3: Buckling stability analysis of pressure vessels

The design and construction process of large LNG storage tank is complex and the cost is high, which is one of the cutting-edge technologies in the energy field and has been monopolized by foreign enterprises for a long time.

Hydraulic + external pressure setting: hydraulic pressure inside the tank: hydrostatic pressure, liquid level height of 43.480m; External pressure on the outer wall of the inner tank: 1000Pa; The bottom surface of the inner tank restrains vertical displacement, and the outer edge of the bottom surface restrains four nodes horizontally.

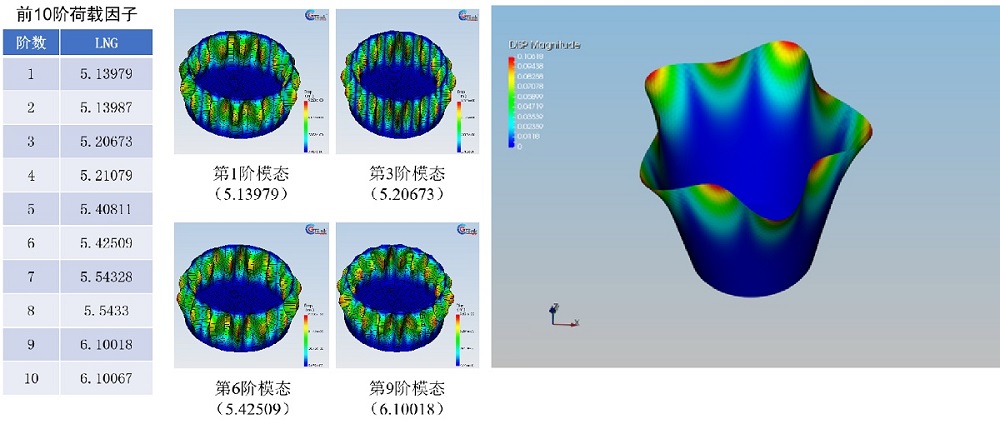

The above figure shows the first 10 order load factors and some buckling modes of the LNG inner tank structure in linear buckling analysis. The critical load under each mode can be obtained by multiplying the load factors with the applied load.

Through nonlinear buckling analysis, the dislocation-load factor curve of the LNG inner tank is finally obtained (as shown in the figure above). The load factor at the peak displacement is 0.04437, then the ultimate bearing capacity of the LNG inner tank = total load *0.04437.

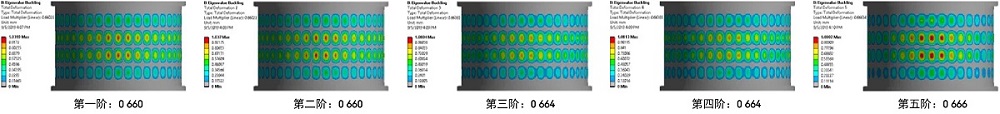

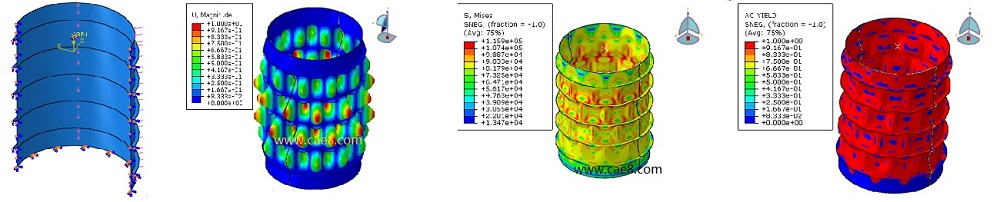

Case 4: Nonlinear buckling analysis of thin-walled pipes

The thin wall of the cylinder is made of 2024-T3 aluminum alloy, supported by five layers of Z-shaped circumferential stiffeners. The two ends of the thin wall of the cylinder are sealed by two thick cover plates (thickness of 25mm), and each is reinforced by an L-shaped riveting strip. The cylindrical thin wall is subjected to the external uniform pressure, which causes the local buckling between the two Z-shaped stiffeners on the thin wall of the cylinder, and finally leads to the failure of the structure.

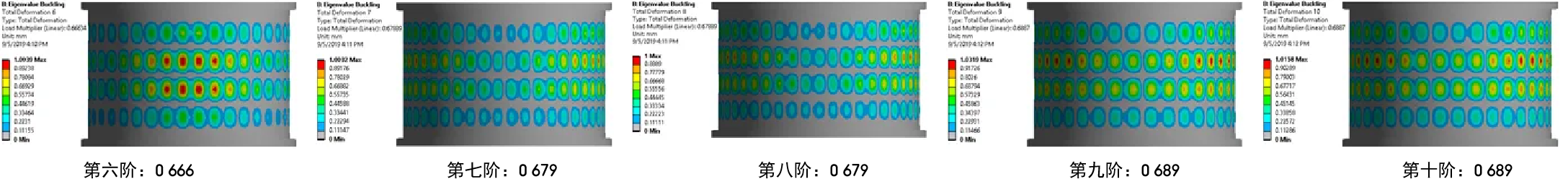

The following figure shows the curve result of axial displacement of a node in the middle of the bottom cover plate changing with external load. It is not difficult to find that when the external load reaches about 0.15MPa, the curvature of the curve changes greatly, which indicates that the structure has a buckling failure, and the corresponding load is the buckling load of the structure

Case 5: Linear and nonlinear buckling analysis of thin-walled cylinders

This case is to enhance the linear and nonlinear (post-buckling) buckling simulation of thin-walled cylinders. The results show that the load on the cylinder includes vertical concentration pressure and uniform distribution pressure on the outer wall. Under this load, the critical load of structural instability can be obtained by linear buckling analysis, and the eigenvalue of the first-order buckling mode λ=639.17. While nonlinear buckling can take into account the initial geometric defects, the material yield, and the failure of the structure when the load continues to increase

。

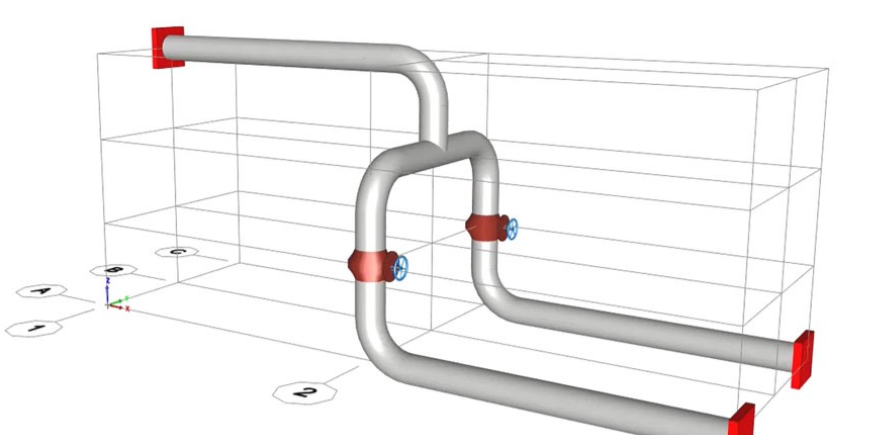

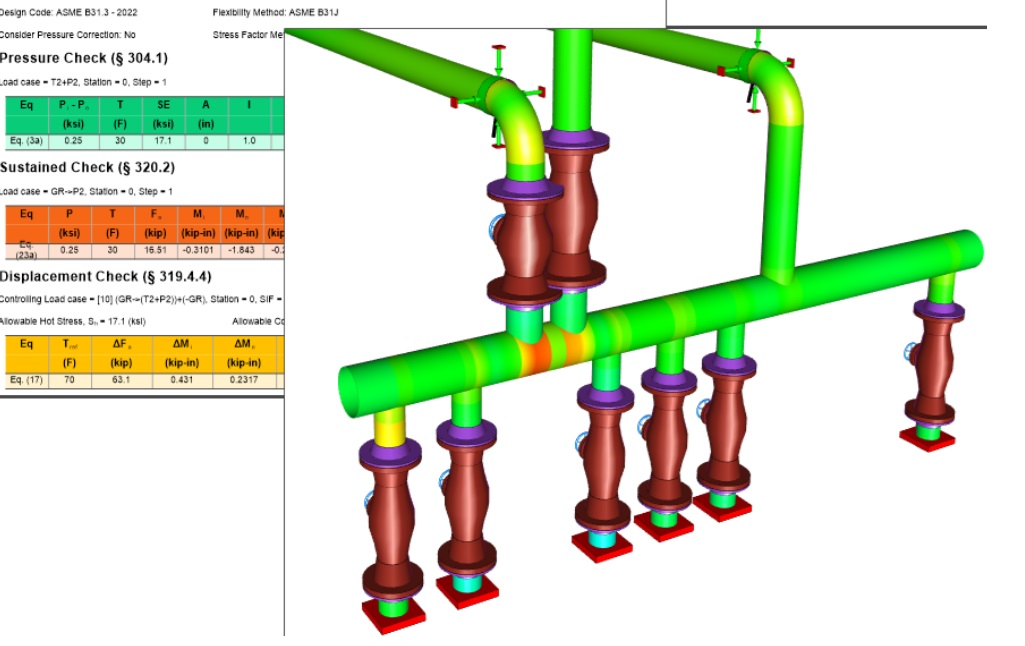

Case 6: Oil pipeline stress analysis

The practical application technology of finite element analysis in petrochemical industry is very extensive, covering the advanced science and engineering technology in the world today. Especially with the continuous development of modern petroleum science and technology, it has become a new trend to combine the original theories and methods of petroleum and other disciplines with the continuous development of computer technology. The stress analysis of pressure vessel can solve the technical problems in oil and gas industry by means of multi-disciplinary joint research and modern computer hardware and software technology.

Spherical storage tank

Oil, as the blood of modern economy, determines the development of national economy to a certain extent. The industry involves a series of upstream exploration, mining, storage, transport, distribution and other processes, as well as downstream oil refining, petrochemical and other large-scale industrial projects. The application of advanced digital stress analysis means covers the whole life cycle of large-scale petrochemical engineering projects, provides intelligent software platform tools, from EPC to digital delivery, and builds digital factories for owners to reduce costs and increase efficiency of large-scale petrochemical projects. Product business includes project front-end engineering, design, construction, operation and maintenance, life extension/decommissioning and other stages. Specific functions include preliminary data collection and planning, equipment data management and modeling, process system design, three-dimensional layout design, three-dimensional information model browsing, instrument design, electrical design, design process management, material fine management, construction visualization management, digital delivery, project information integration management, etc. For design enterprises, construction enterprises, general contract engineering companies, owners and other related parties to provide one-stop full life cycle digital factory information solutions.

Diversified service types

Pressure vessel stress analysis, including project undertaking, hardware and software selection and configuration, specialized customized secondary development, technical training, project supply chain management, personnel training, fixed-point technical support, etc., to maximize the benefit of customer investment.

Statement: This article is original from the official website of Le Tu wisdom, please indicate the source.

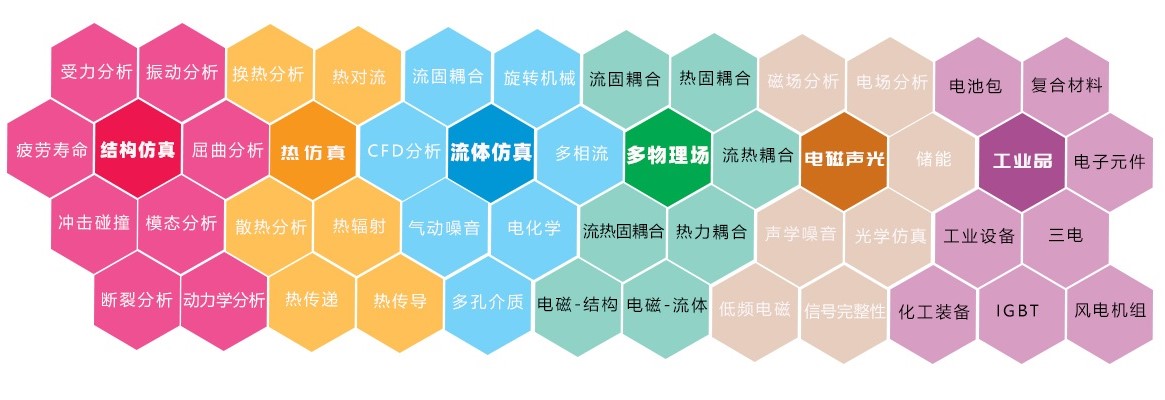

See more cases: Heat dissipation analysis Thermal Simulation Analysis Collision Analysis Modal Analysis CFD Analysis Electromagnetic Field Simulation Analysis Drop analysis Fatigue analysis Pressure vessel Stress analysis

I guess you may have the following questions right now:

- What can you do? How much does it cost?

- How long will it take? What do I need to do?

- What information needs to be provided?

- How was it After sale?

It is difficult to have a standard answer to the same question because everyone has different emphasis. Please fill in the form information or directly online contact, we will give you the most appropriate answer!