Motor NVH performance development to reduce noise and improve service life

Business Introduction:

Letu Company is a professional service provider for NVH simulation and multi-physical field finite element analysis. The NVH simulation team is proficient in NVH simulation optimization in high-end manufacturing fields such as electrical machinery and appliances, power equipment, mechanical equipment, and automobiles, as well as in providing solutions for the standardized process of NVH simulation. It aims to improve the product development level for our clients, shorten the product development cycle, and reduce product development costs, enabling them to take a leading position in the fierce product competition.

Application Value of NVH Simulation Optimization:

Electric motors are complex systems. Due to this complexity and the non-linear coupled physics that govern the magnetic and structural behaviors of these systems, the acoustic noise level in applications is not easily predictable without proper modeling and simulation. Relying solely on experimental methods in the design and optimization of silent motors will significantly increase the cost and time of design modifications. It has been proven that NVH problems discovered during prototype testing are costly to correct in terms of design changes and will delay the production cycle. This is where finite element simulation comes into play.

Cases of NVH Simulation Optimization:

The following lists several of the most common types of electric motors in the motor industry and briefly introduces the application of NVH simulation optimization for electric motors (NVH: Noise, Vibration, and Harshness).

Case 1 of NVH Simulation Optimization - NVH Optimization of Asynchronous Motors

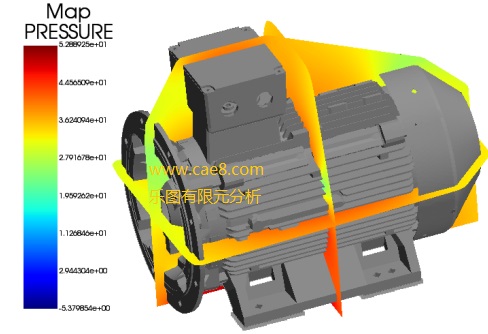

In this case, the possibility of noise generation is judged through modal analysis and electromagnetic force distribution analysis. Of course, in practical applications, CFD (Computational Fluid Dynamics) aerodynamic noise factors also need to be considered, but they will not be summarized here for the time being.

Mechanical Excitation Sources

"Electric motor" is a general term for machines such as electric motors and generators. Their main function is to convert electrical energy into mechanical energy and vice versa. During the operation of these complex machines, there are multiple sources that can cause them to generate vibrations and noise, such as imperfect mechanical assembly, rotor and fan aerodynamics, and electromagnetic forces.

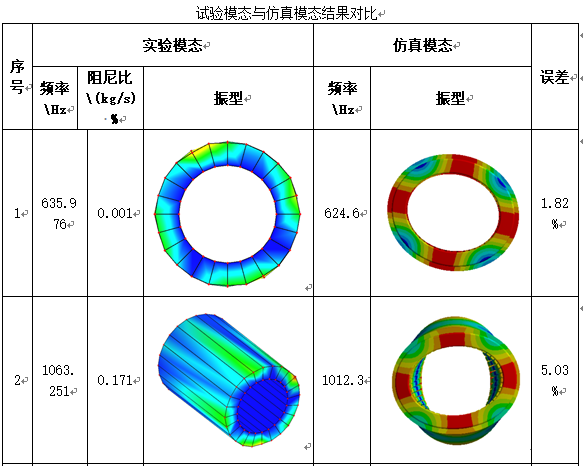

The following pictures show the modal and operating deformation (animation) of the asynchronous motor.

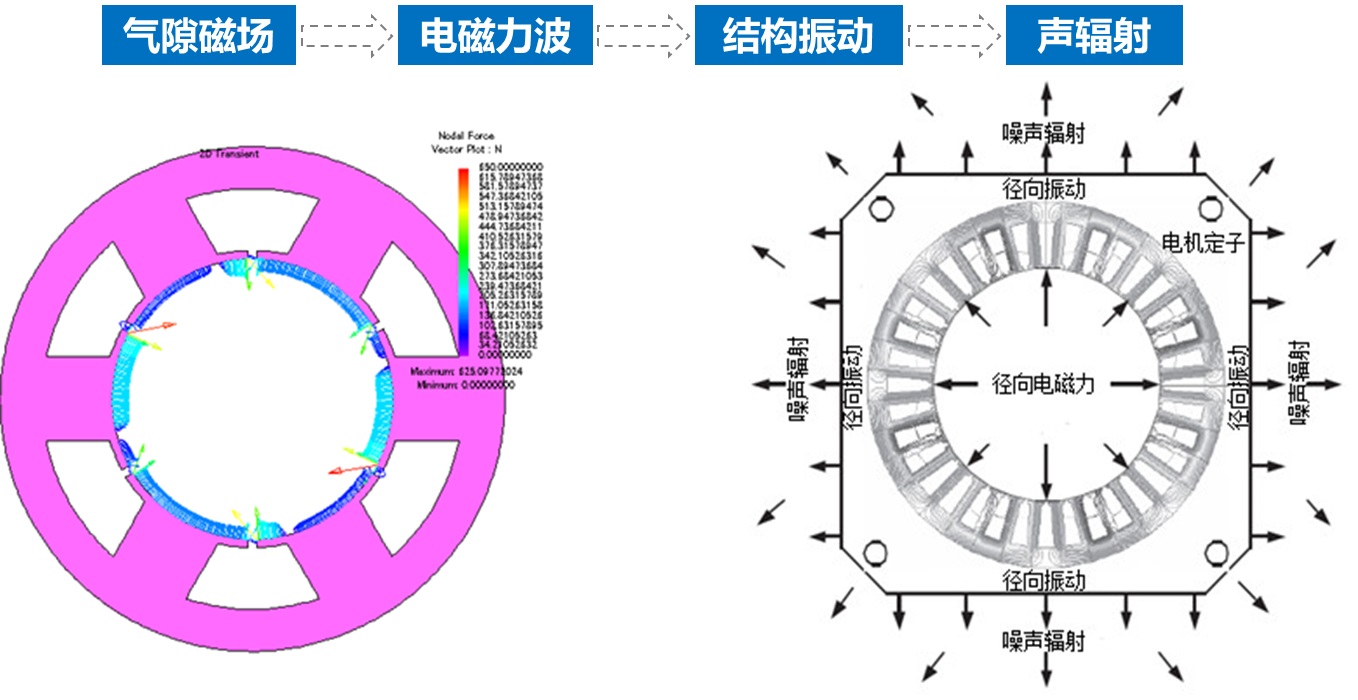

Electromagnetic Excitation Sources

Electromagnetic forces, especially radial forces, are the main causes of unpleasant sounds generated by electric motors. Electromagnetic forces have two components: radial forces and tangential forces. Radial forces do not contribute to energy conversion when generating vibrations. On the other hand, tangential forces promote energy conversion through the average electromagnetic torque and promote noise and vibration through torque pulsations.

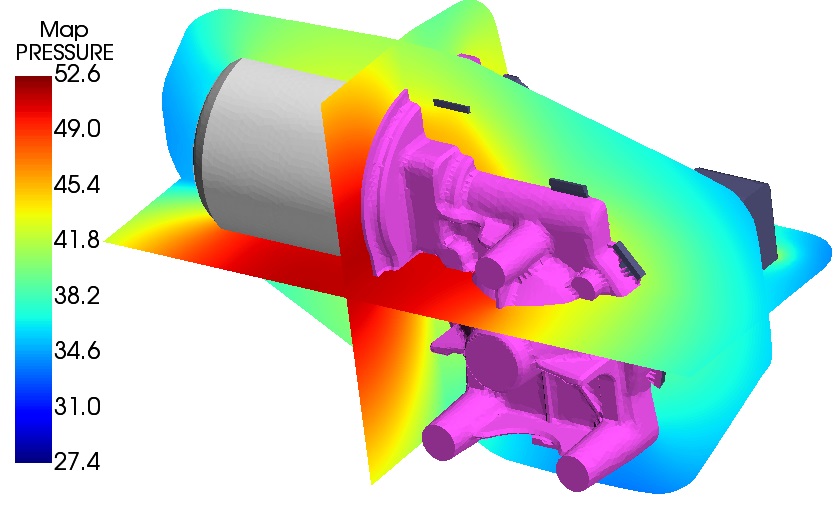

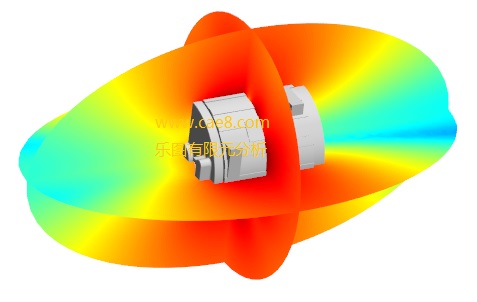

The following picture shows the distribution of the noise radiation cloud chart of the asynchronous motor.

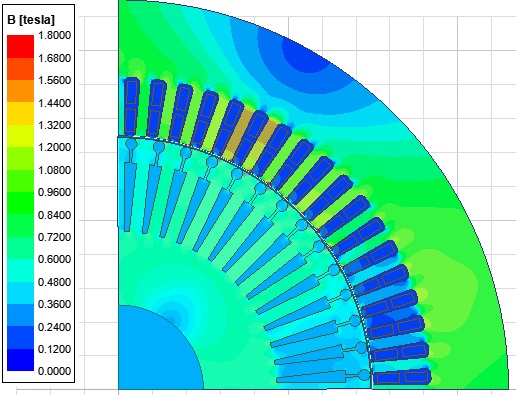

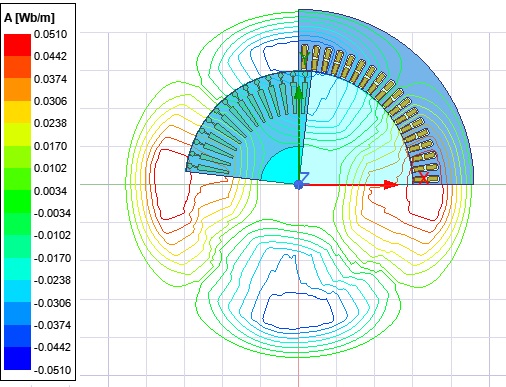

The following picture shows the magnetic flux density cloud chart and magnetic field lines chart of the asynchronous motor.

The following picture shows the radial electromagnetic force and tangential electromagnetic force (animation).

Case 2 of NVH Simulation Optimization - NVH Optimization of DC Motors

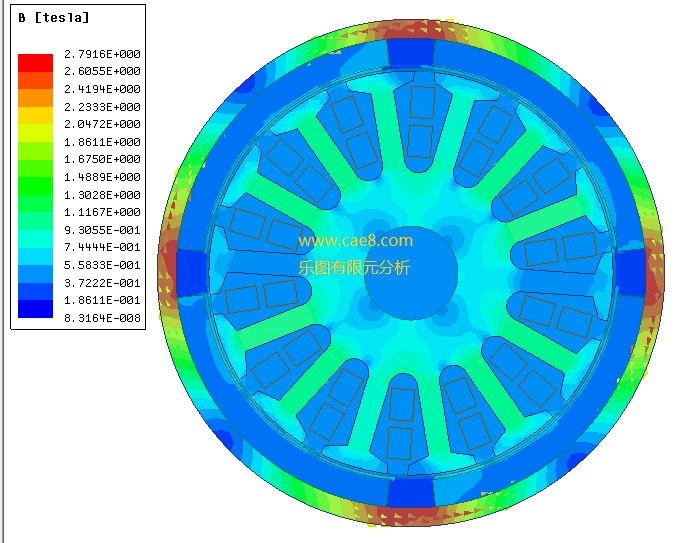

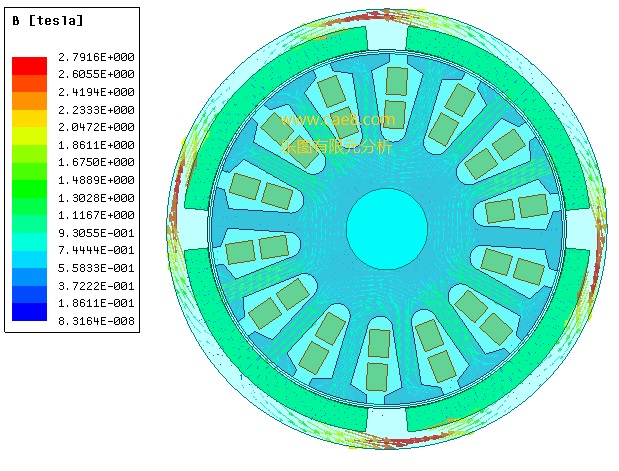

The following picture shows the distribution of the magnetic flux density cloud chart of the DC motor.

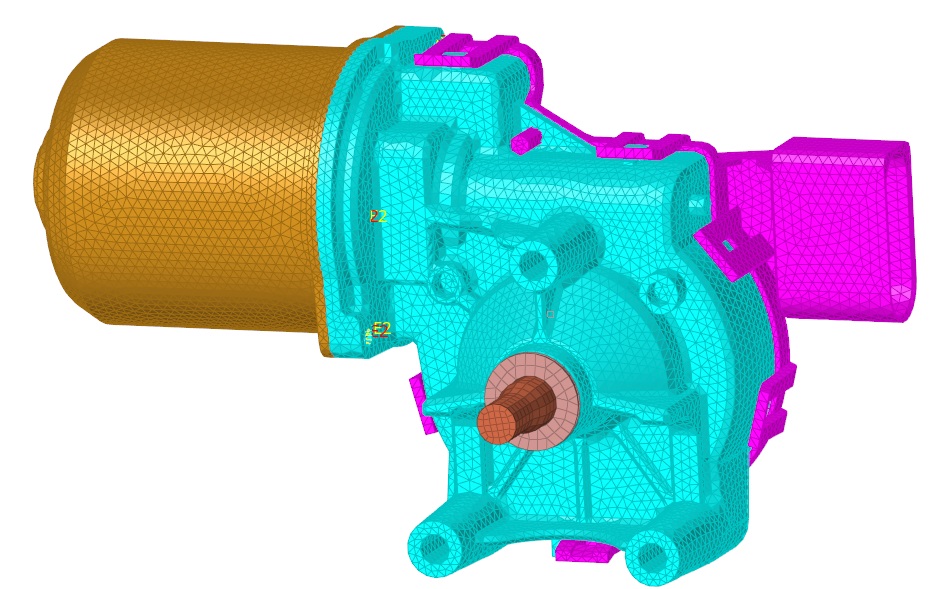

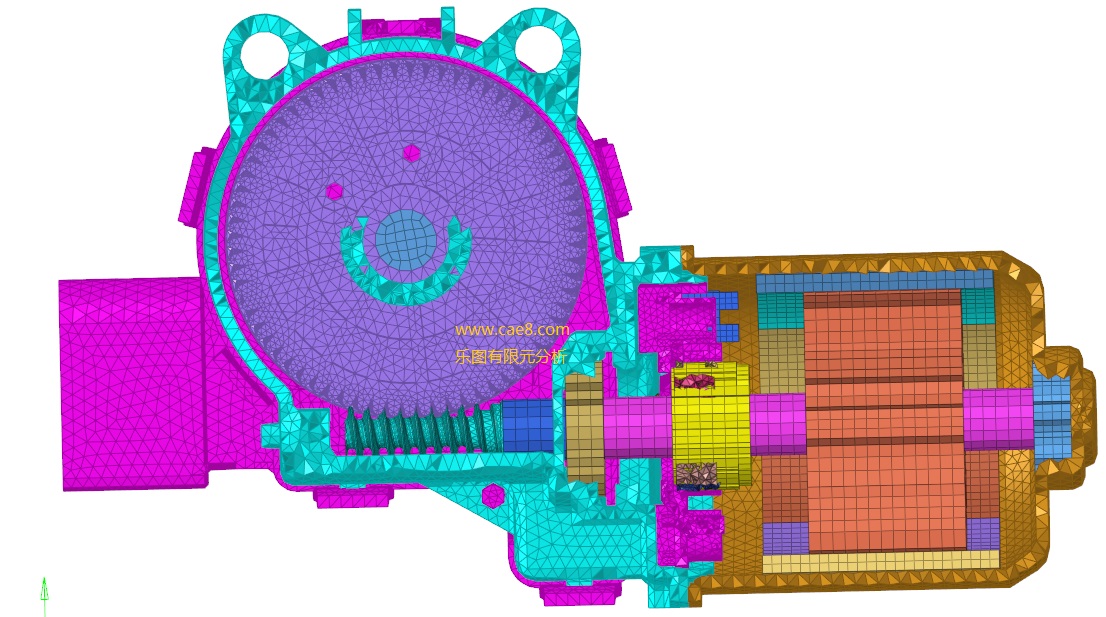

The following picture shows the mesh model of the brushed DC motor.

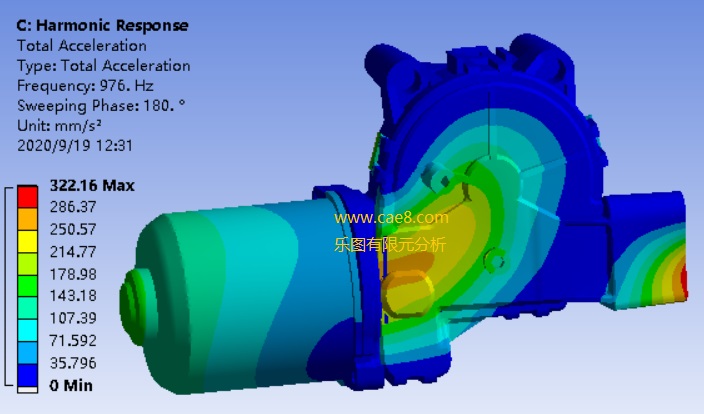

The following picture shows the distribution of the vibration and noise cloud chart of the brushed DC motor.

Case 3 of NVH Simulation Optimization - NVH Optimization of Permanent Magnet Synchronous Motors

What Causes Noise in Electric Motors?

1. Mechanical Excitation Sources

"Electric motor" is a general term for machines such as electric motors and generators. Their main function is to convert electrical energy into mechanical energy and vice versa. During the operation of these complex machines, there are multiple sources that can cause them to generate vibrations and noise, such as imperfect mechanical assembly, rotor and fan aerodynamics, and electromagnetic forces. Among them, electromagnetic forces, especially radial forces, are the main causes of unpleasant sounds generated by electric motors.

2. Electromagnetic Excitation Sources

Electromagnetic forces have two components: radial forces and tangential forces. Radial forces do not contribute to energy conversion when generating vibrations. On the other hand, tangential forces promote energy conversion through the average electromagnetic torque and promote noise and vibration through torque pulsations.

3. Aerodynamic Excitation Sources

When the cooling fan is in operation, the aerodynamic noise it generates is directly transmitted to the surrounding space, while forces and vibrations are transmitted through the mechanical structure and then radiated to the surrounding space through surface displacement.

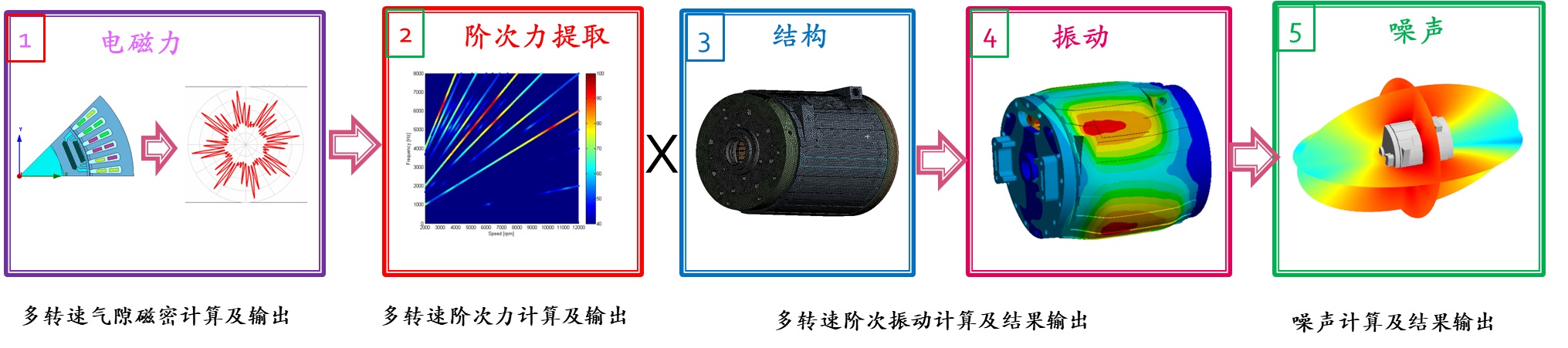

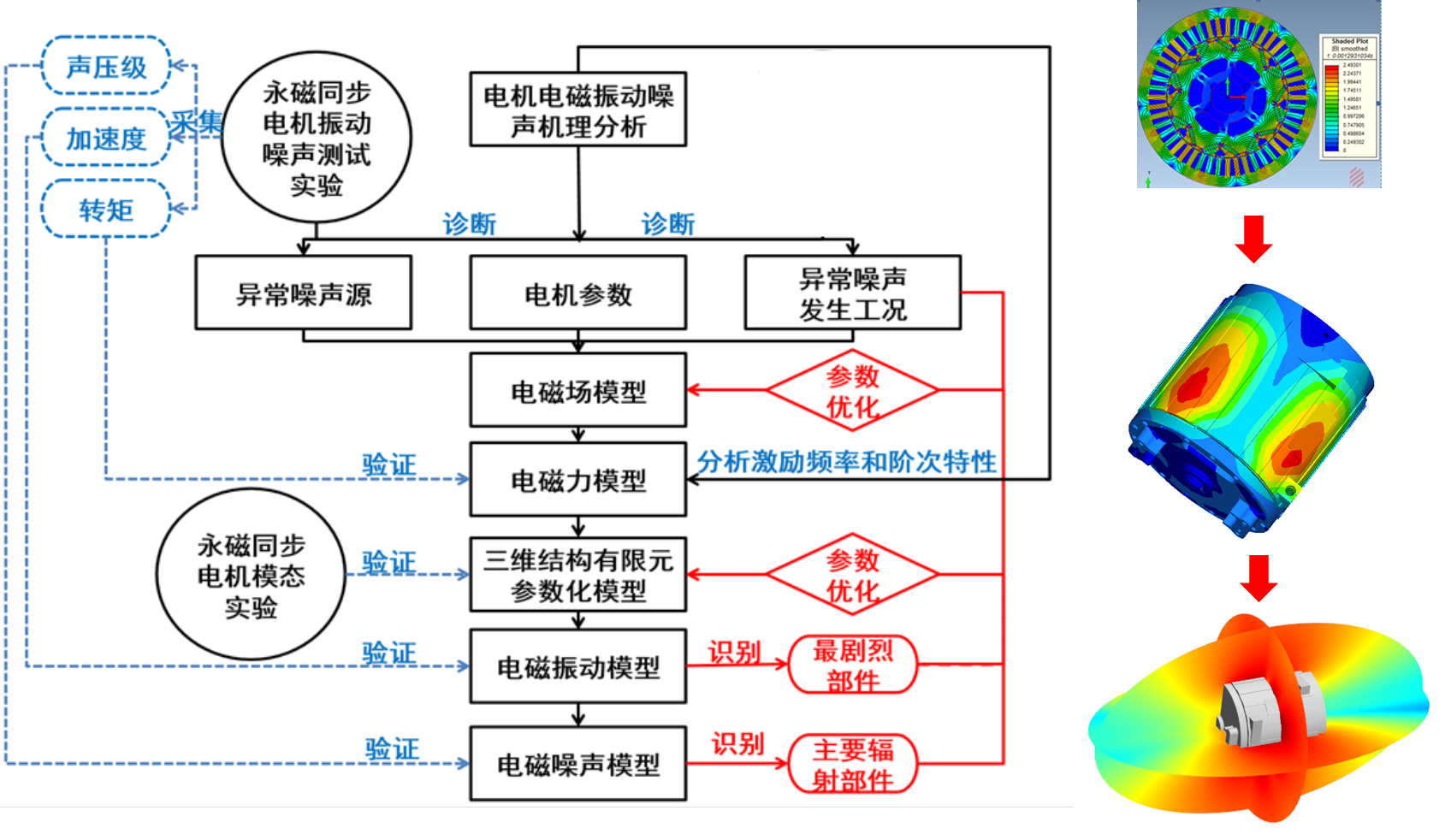

The following picture shows the technology roadmap for multi-physical field simulation and optimization of motor noise in the forward research and development type (Part 1).

The following picture shows the technology roadmap for multi-physical field simulation and optimization of motor noise in the fault diagnosis type (Part 2).

The following picture shows the flowchart of the software tool chain for motor noise analysis.

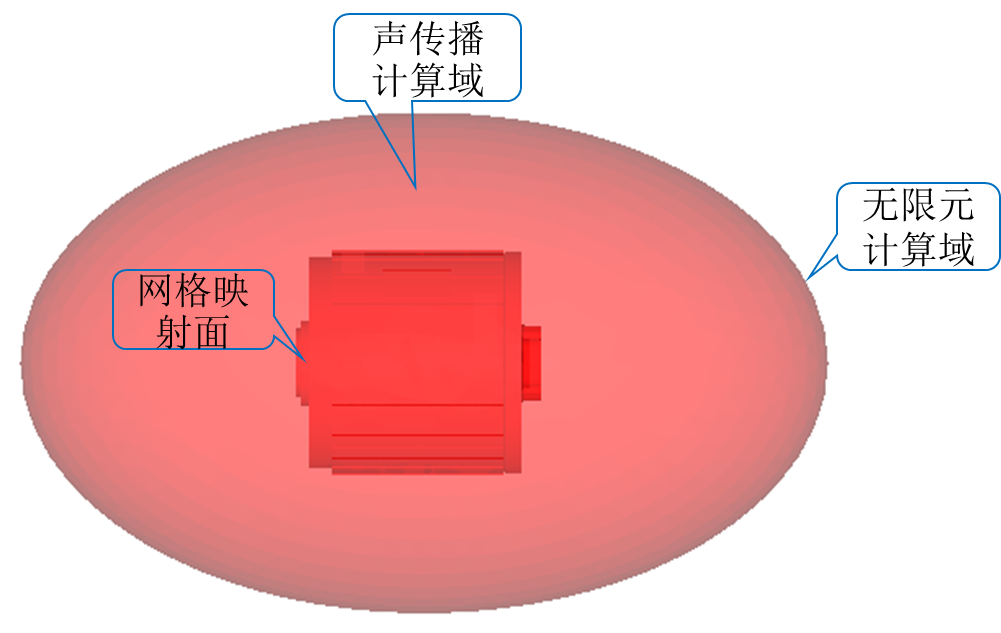

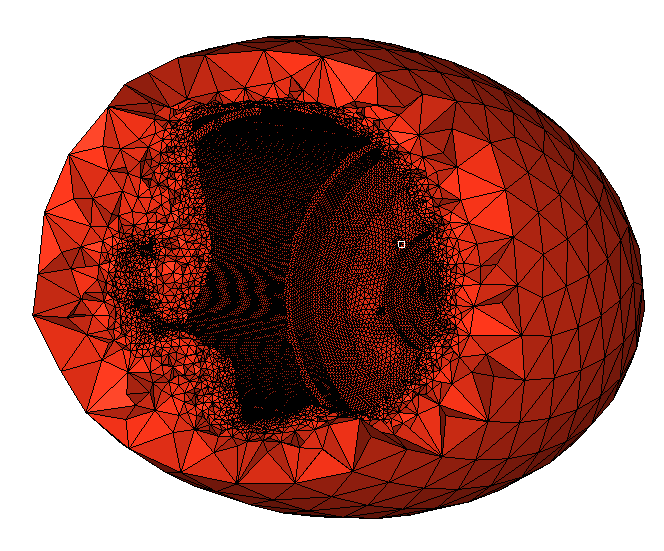

The following picture shows the schematic diagram of the acoustic calculation mesh model.

The following picture shows the schematic diagram of the arrangement of vibration measurement points under the motor load condition.

The following picture shows the schematic diagram of the arrangement of microphone measurement points for motor noise.

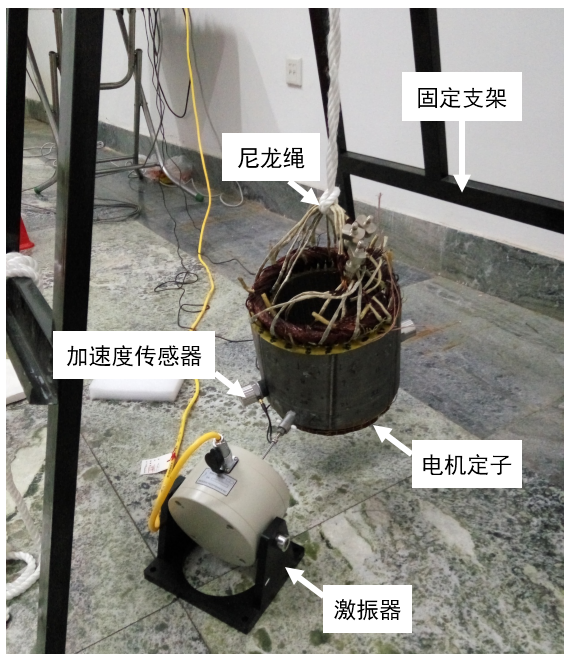

The following picture shows the schematic diagram of motor modal testing.

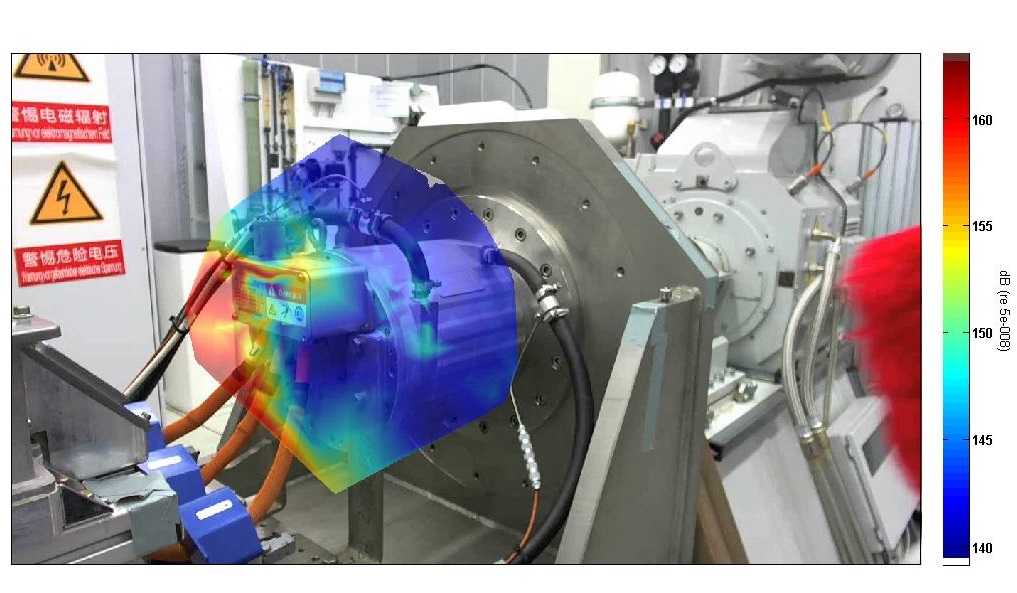

The following picture shows the bench test of motor vibration and noise.

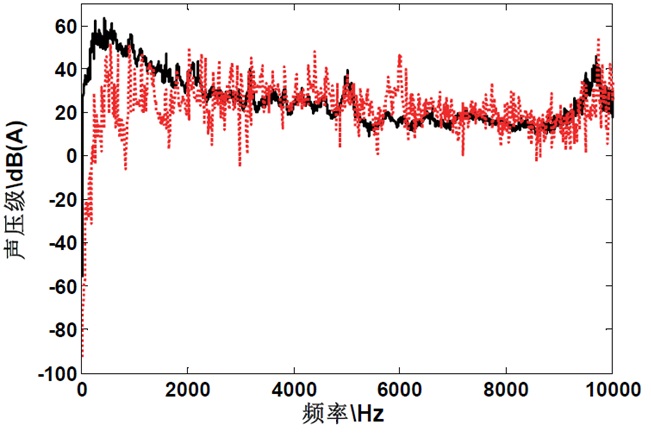

The following picture shows the calculation results of the noise of the permanent magnet synchronous motor in the simulation.

Summary: NVH is an important design criterion for many applications involving electric motors, ranging from medical equipment to electric vehicles and household appliances. High levels of vibration can shorten the service life of electric motors, while loud sounds can cause noise pollution and have an adverse impact on health and comfort. In addition, in critical applications such as military equipment, NVH can generate vibro-acoustic characteristics. National and international standards and certification requirements limit the vibration and audible noise generated by equipment to an acceptable level.

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice