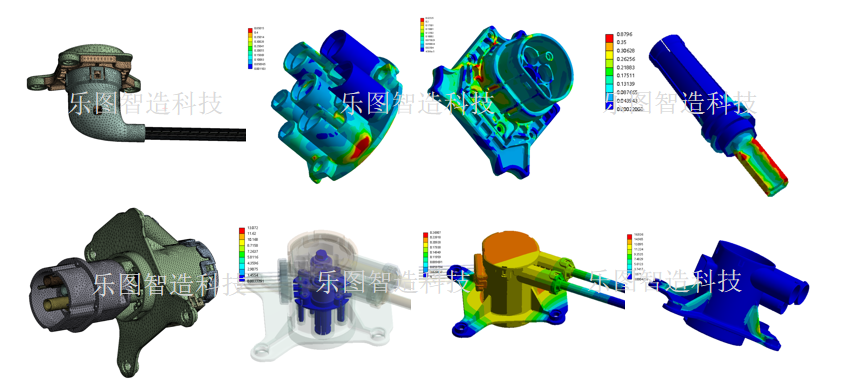

Vibration analysis/Modal analysis for auto parts and energy storage industry

Business introduction:

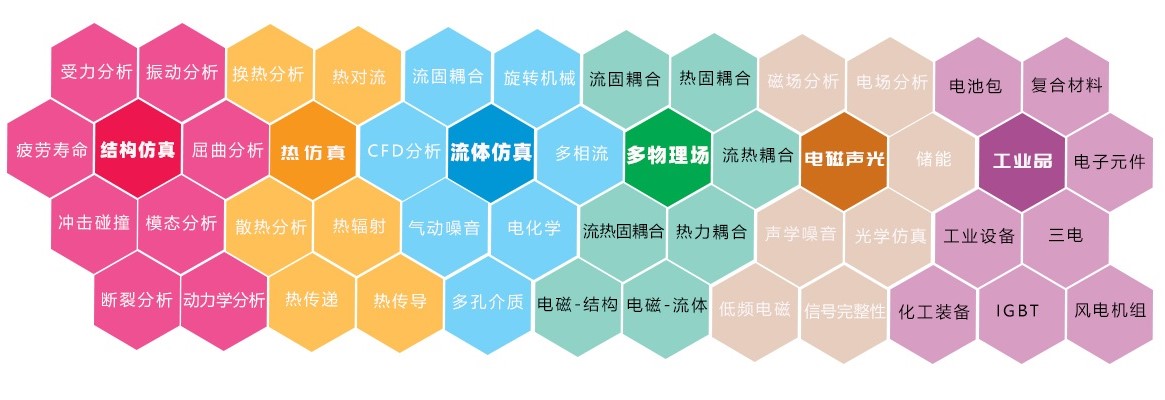

Vehicles, machine tools, machinery all kinds of equipment modal analysis, vibration analysis strength verification, NVH performance vibration and noise reduction, professional senior finite element simulation team.

Solve all kinds of noise related problems, from large car noise to small mobile phone sound optimization of various sound problems. For example, the sound transmission problem of mobile phones, submarine noise, ultrasonic piezoelectric ceramics, mufflers, intake system noise, acoustics, engine room wall insulation, turbine noise, fan noise, machine vibration noise, etc.

Common vibration analysis types: steady vibration, shock vibration, random vibration.

1. Steady state vibration analysis:

It is an ambient vibration with little change in vibration level during the observation time. Including rotary machinery (such as fans, generators, motors, water pumps, etc.) and reciprocating machinery (such as diesel engines, air compressors, textile machines, etc.) caused by environmental vibration.

2. Impact and vibration analysis:

It is an environmental vibration with sudden changes in vibration level, including the environmental vibration caused by forging machines (such as forging hammers, punches, etc.) and construction machinery (such as pile drivers, etc.) and blasting.

3. Random vibration analysis:

It is the environmental vibration that cannot be determined in advance, including road traffic vibration, bridge vibration and resident life vibration (such as house decoration, kitchen operation, etc.)

Understand the team backbone

Vibration analysis case: (Only part of the content is shown)

Case 1- Vibration analysis of charging seat

Case 2- Body in White modal analysis

Left: first order torsion right: first order bending

The part vibrates at the natural frequency, and the shape of its displacement is called the mode. Each mode will have a mode frequency, and there will be a corresponding mode mode mode at the corresponding mode frequency. Among the body modes, the frequency of the first order bending mode and the frequency of the first order torsional mode of the body are the most worthy of our attention. The following figure shows the calculation results of the first order bending mode and the first order torsional mode of the body in white. The value in the upper right corner indicates that the first-order torsional mode frequency of the body is 35.34 Hz, and the first-order bending mode frequency of the body is 50.78 Hz.

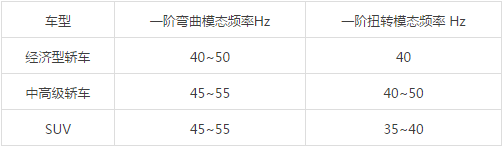

The modal frequency requirements of first-order bending and first-order torsion of body in white of several types are commonly used. The modal data of this model is consistent with the normal conditions of SUVs.

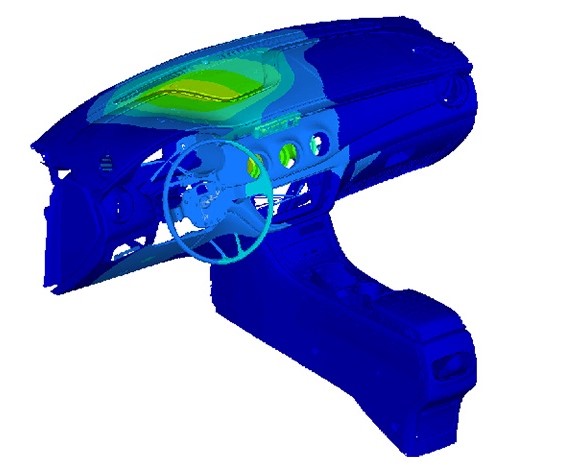

Case 3: Dashboard modal analysis

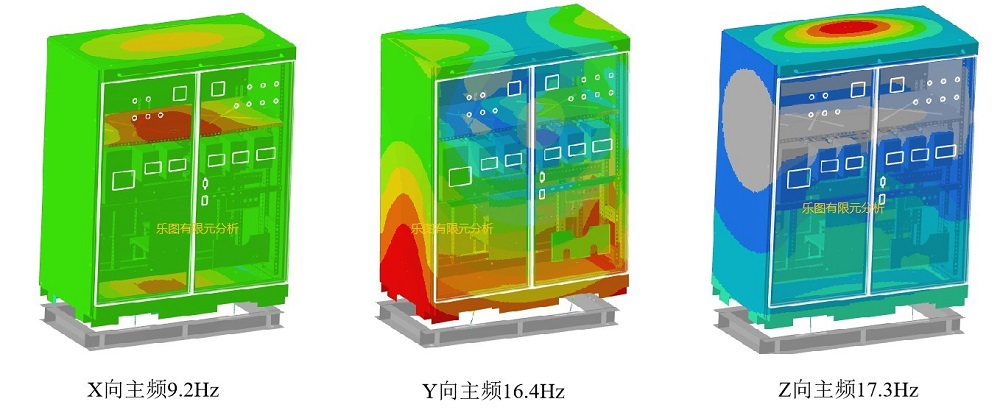

Case 4- Modal analysis of distribution box

Modal analysis is a method to study the dynamic characteristics of structures, which is generally used in the field of engineering vibration. Among them, mode refers to the natural vibration characteristics of mechanical structure, and each mode has a specific natural frequency, damping ratio and mode mode.

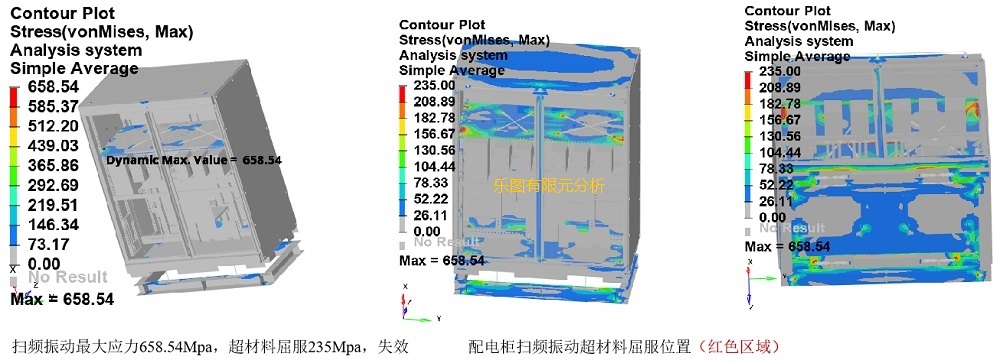

Case 5- Distribution box vibration fatigue analysis - sweep frequency vibration analysis

Vibration analysis knowledge Answer:

1. What is Modal analysis?

Modal analysis is a method to study the dynamic characteristics of structures. Modal analysis refers to the process of solving the modal modes and vibration frequencies of multi-degree-of-freedom systems.

Modal analysis can be simply divided into free modal analysis and constrained modal analysis.

1. Free modal analysis means that no constraints are defined during modal analysis. A correctly connected assembly or a single part will have a rigid body mode with zero frequency in the first 6 orders (that is, the modal frequency is very small, usually less than 0.01, and the theoretical solution is zero, but there will be errors in numerical calculation, so it is not zero). At this time, the model does not deform, but only moves and rotates along three axes.

2. Constrained modal analysis refers to applying complete constraints when doing modal analysis, so that the model will not appear rigid body mode.

2. What is the role of modal analysis?

1. Evaluate whether resonance will occur, NVH performance development elements.

Modal analysis can determine the natural frequency and mode, according to the natural frequency, mode and excitation, you can judge whether the model will resonate under a specific excitation.

2. Basis of other vibration analysis research,

Modal analysis is the basis of vibration analysis such as frequency response analysis, random vibration analysis and response spectrum analysis.

3. Identify the weak location of the structure,

In modal analysis, the strain energy density and displacement of the structure can be output. Generally, the region with a large strain energy density is the location with relatively small stiffness. Reinforcement or thickening at the location with relatively small stiffness can avoid local structural weakness to a certain extent.

4. Facilitate quick inspection of assembly connection relationship,

In the process of finite element analysis, for complex assembly, defining the connection relationship is a time-consuming and laborious thing, less definition of the connection relationship leads to a high possibility of a part "flying off" when doing strength analysis, and free modal analysis can quickly confirm whether the connection relationship between some parts is missed.

5. It is helpful for experimental detection of vibration mode.

If the form of the mode is predicted in advance through simulation analysis, it can be attached more sensors in the area of large displacement, and less sensors in other locations, so that the mode mode can be measured quickly and efficiently.

Charging standard:

According to the difficulty of a specific project, the price of a standard project cannot be unified because cae analysis involves a wide range of engineering differences and different test items, and involves the types of finite element analysis and the differences in their difficulty coefficients. Customer demand-oriented, for each customer to develop and recommend the most suitable product solutions. Honesty, quality first, heart service, win trust.

Statement: This article is original from the official website of Le Tu wisdom, please indicate the source.

查看更多案例: Fatigue analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice