Deformation finite element simulation of medical vascular stent

Undertake Medical Finite Element Analysis Projects

Analysis of pelvis, lumbar spine, cervical spine, shoulder joint, hip joint, elbow joint, knee joint, ankle joint, denture, implant, maxilla and mandible, mucosa, dental crown, etc.

Finite Element Simulation Case of Medical Vascular Stents:

1. Simulation Purpose:

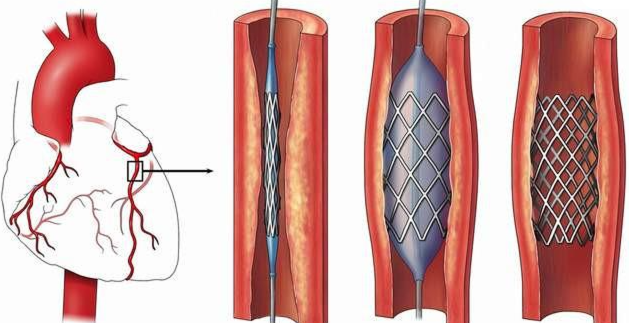

Cardiovascular and cerebrovascular diseases are a major threat to human life and health. Currently, for cardiovascular and cerebrovascular diseases, vascular stents are mainly implanted into blood vessels to support the narrowed or occluded segments of blood vessels, reduce the elastic recoil and remodeling of blood vessels, and maintain the smooth blood flow in the lumen. However, the relatively high restenosis rate of current stents has become the biggest obstacle to their further development. Therefore, structural optimization design for vascular stents is carried out to provide technical guarantees for improving the stability of stents in work, their service life, and ensuring no recurrence after surgery.

2. Overview:

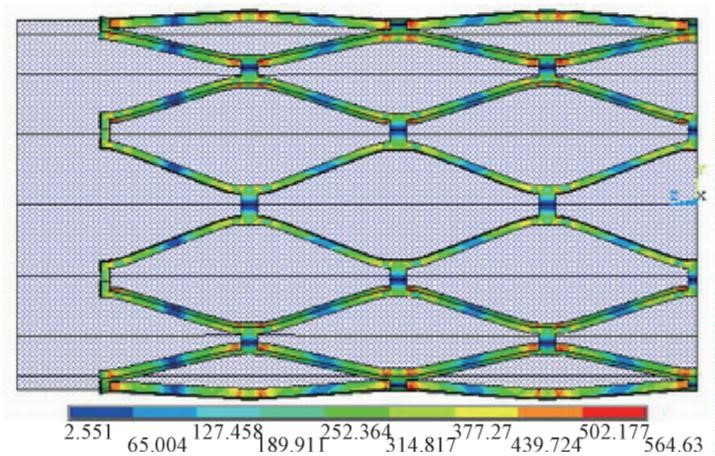

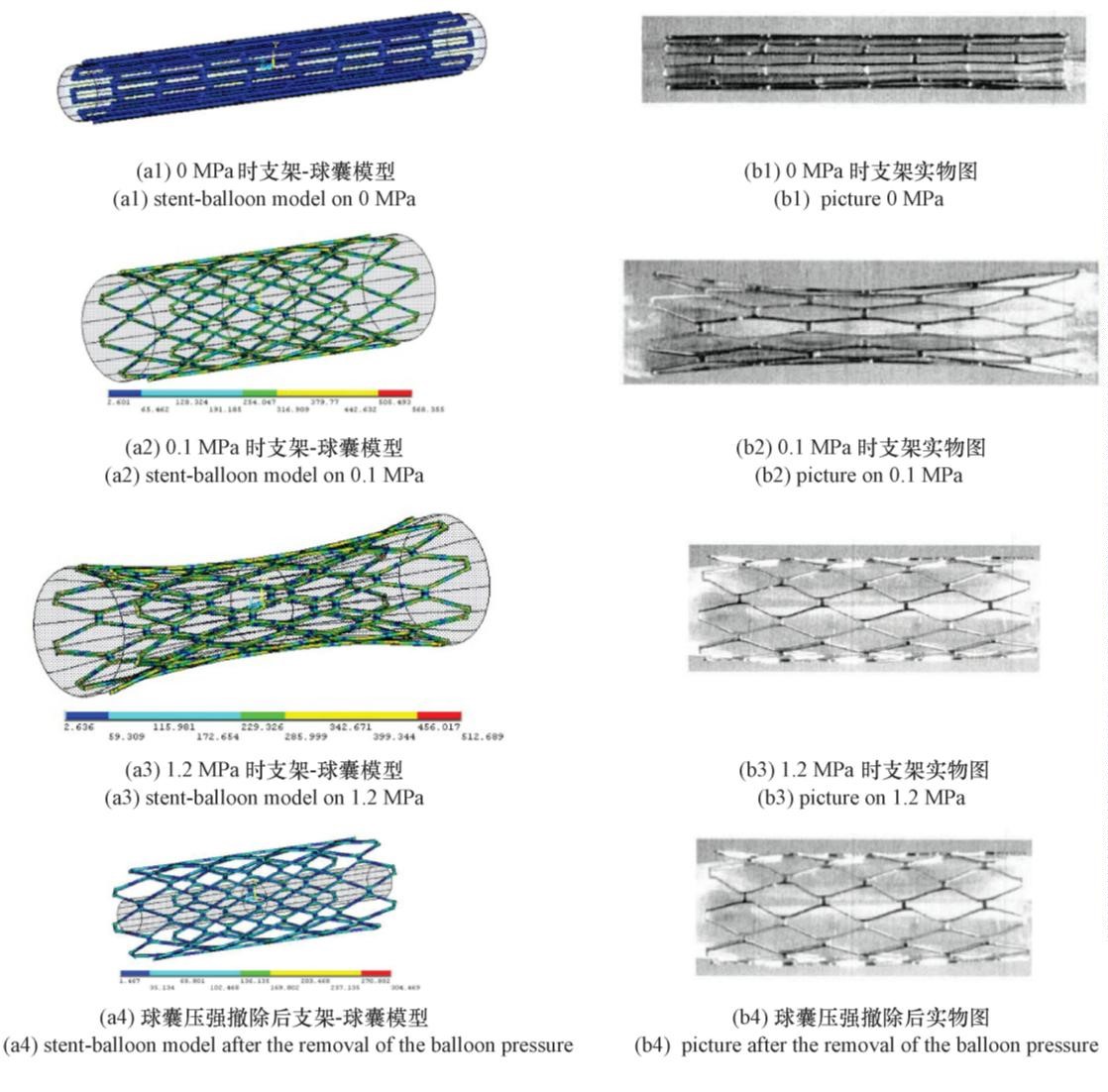

During the research and development process of new stents, researchers usually adopt the method of in vitro expansion simulation to obtain the performance parameters of stents. Among the methods of domestic and foreign researchers, they can often only conduct local simulations on the stent structure and cannot obtain the overall performance data. Using the "volume-controlled" balloon-stent model and the finite element analysis software ANSYS, the stress distribution and deformation during the overall expansion process of the stent are simulated, so as to find out structural defects and optimize the performance of the stent.

3. Stress Results:

Through the simulation analysis of the stent model, the positions where the maximum stress occurs and plastic deformation occurs can be predicted relatively accurately. In the design of new stents, if a balloon-stent model is established in advance to simulate the expansion process, find the position and magnitude of the maximum stress during expansion, and compare the maximum stress with the tensile strength of the stent material, when the tensile strength of the stent material is less than the maximum stress, try to improve the tensile strength of the material, then the stent can be prevented from being damaged due to excessive expansion.

4. Stent Expansion Comparison Results

Through the simulation analysis of the stent model, the positions where the maximum stress occurs and plastic deformation occurs can be predicted relatively accurately. In the design of new stents, if a balloon-stent model is established in advance to simulate the expansion process, find the position and magnitude of the maximum stress during expansion, and compare the maximum stress with the tensile strength of the stent material, when the tensile strength of the stent material is less than the maximum stress, try to improve the tensile strength of the material, then the stent can be prevented from being damaged due to excessive expansion. The diamond-shaped stent mentioned above has a maximum stress during the expansion process that is less than the tensile strength of the material, so the stent will not be damaged and conforms to the clinical application standards.

5. Summary:

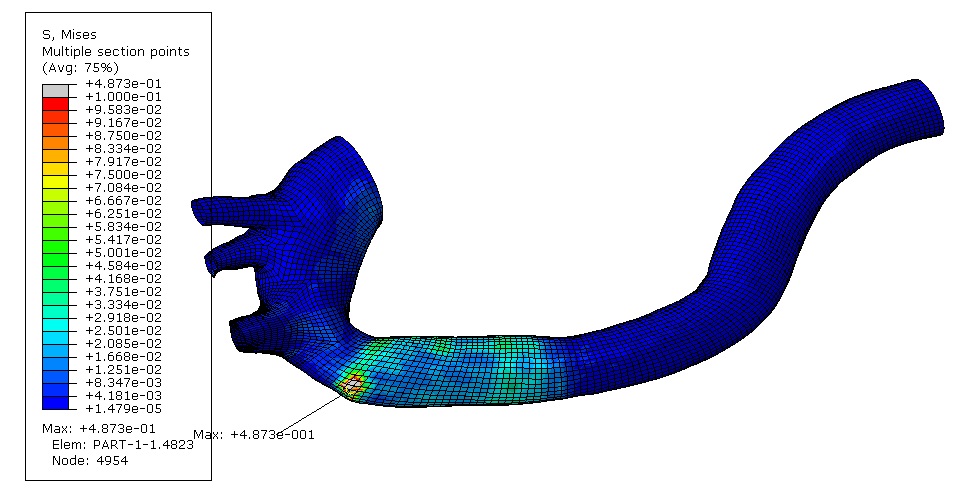

1. The results of the simulation analysis show the maximum stress of blood vessels after stent implantation.

2. The mechanical behavior of stents in blood vessels is very complex. Whether it is boundary conditions or material parameters, accurate parameters or better simplification methods are needed to obtain analysis results that meet the actual needs of medical engineering analysis.

3. Using the knowledge of finite element analysis, medical researchers can effectively improve the design of stents and optimize their applications in biomedical applications. In addition to medical equipment required in surgical procedures, finite element analysis technology is also widely used in other fields of biomedicine and provides more help for people's life and health. Conducting simulation research on vascular stents can reduce the number of experiments, save working time, and reduce experimental costs.

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice