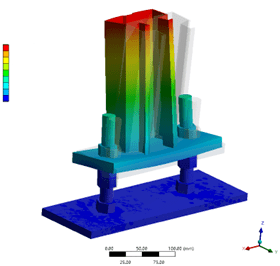

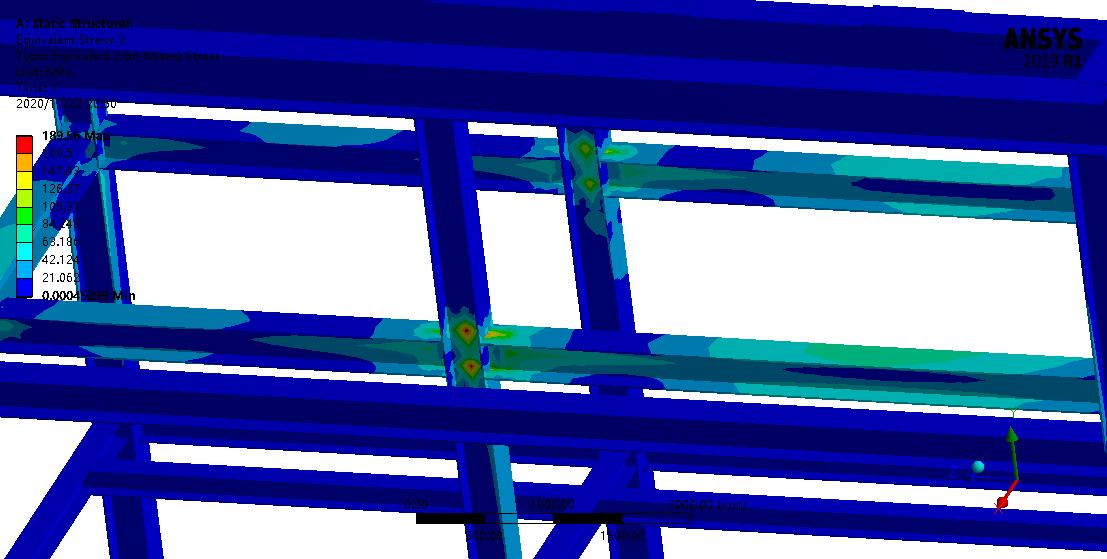

FIG. 17 Machine tool deformation cloud image with 16 fulcrum points

Business Content:

Undertake various finite element analysis of storage racks, structural stress analysis of steel structures calculations, stress analysis of container lifting, stress analysis of pressure vessels, professional finite element simulation technical services in accordance with GB national standards, EU standards, and ASME standards, serving industries such as petrochemical, transportation, civil construction, and nuclear power energy.

Learn about the Team's Key Members

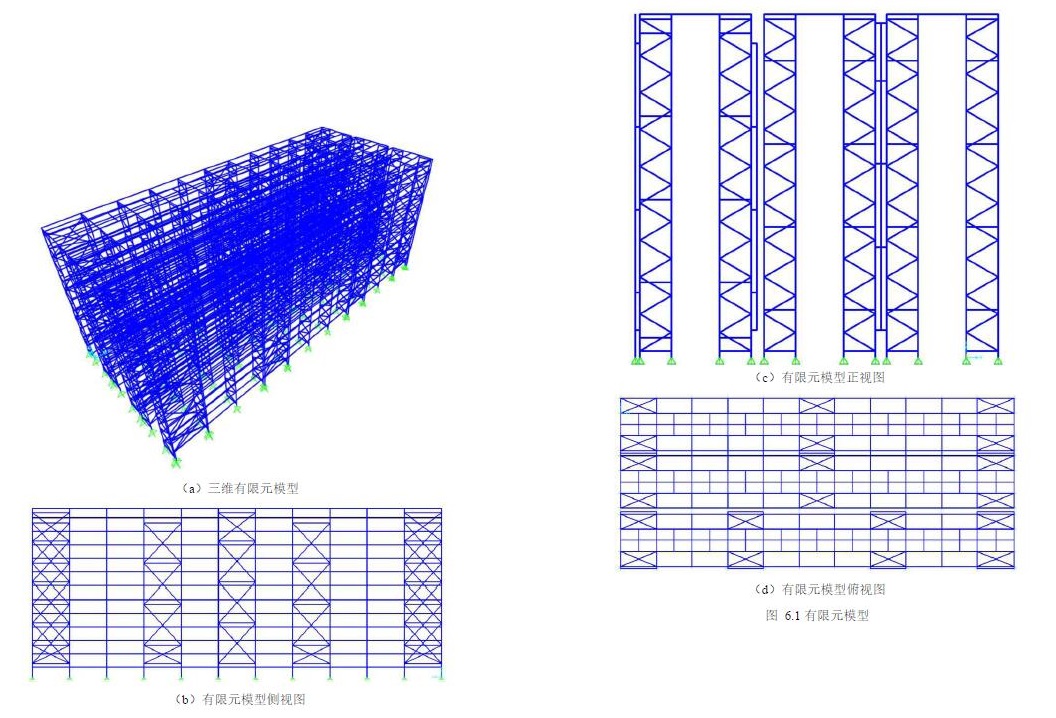

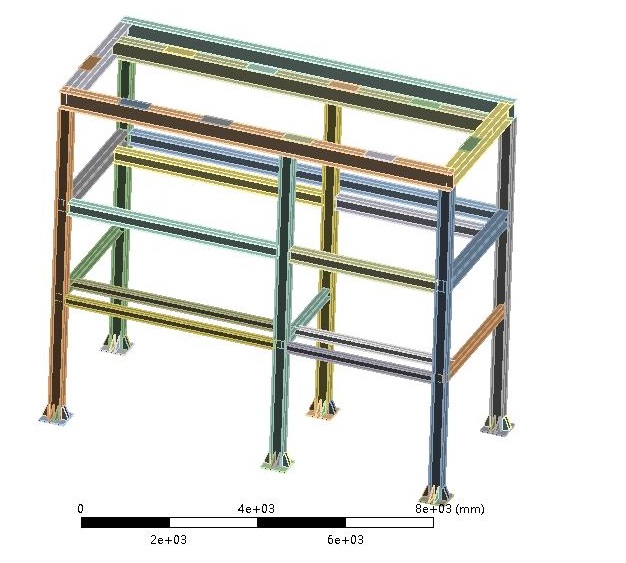

Case 1: Finite Element Analysis of Automated Storage and Retrieval System (ASRS) Racks

The stress analysis of storage racks plays a crucial role in the modern logistics industry. With the continuous development of warehousing technology, storage racks, as an important part of the logistics system, have received increasing attention regarding their stability and safety. Finite element analysis, as an advanced numerical analysis method, provides strong support for the design and optimization of storage racks.

The structure of ASRS racks is large and the load is complex. For the convenience of transportation, they are designed as detachable connection structures, so most of the steel structures of ASRS racks are connected by high-strength bolts. When the steel structure of the storage rack is subjected to wind load, snow load, earthquake load, and roof maintenance load, whether the rack has sufficient strength, stiffness, and stability is the most concerned issue for designers. With the maturity of finite element technology and the development of computer software and hardware, it has been deeply promoted in the field of storage racks, and the finite element analysis of ASRS racks has become an indispensable important tool in the design of steel storage rack structures.

The finite element analysis of ASRS racks usually includes the following working conditions:

Finite Element Analysis of ASRS Racks - Static Analysis:

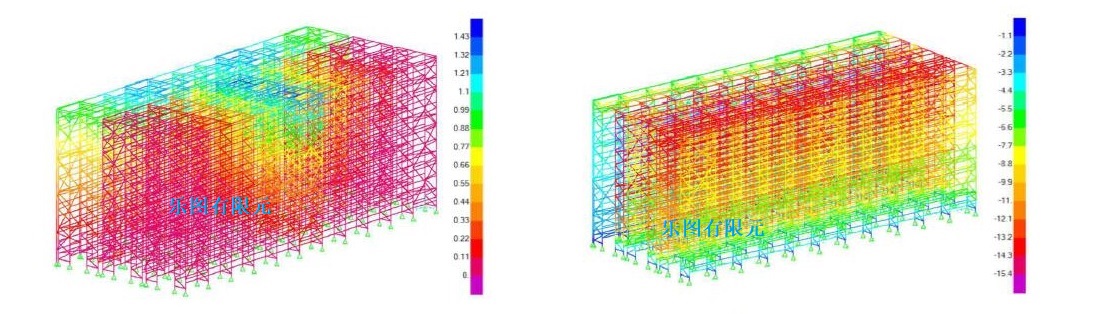

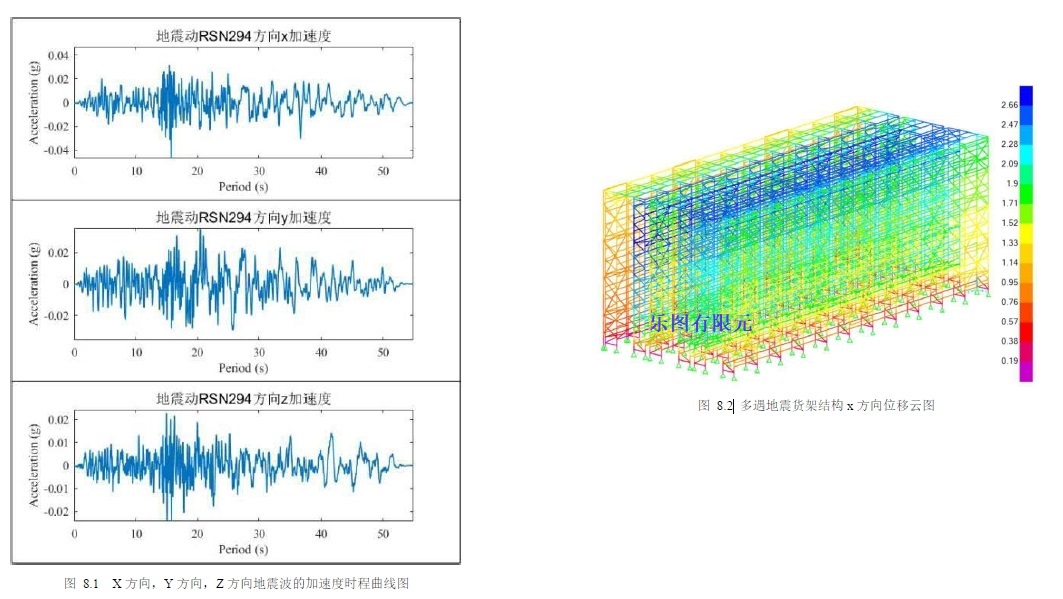

Conduct static analysis on the steel structure of the ASRS racks. During the calculation, consider the combined action of multiple load combinations such as structural self-weight, cargo load, wind load, snow load, and earthquake load. This step is used to determine the displacement and stress distribution law of the structure and find the parts with the weakest strength and the largest stiffness.

Finite Element Analysis of ASRS Racks - Modal Analysis:

Determine the natural frequency and vibration mode of the structure through modal analysis, and explore the actual vibration response, that is, the deformation trend of the structure under the action of various internal or external vibration sources within a specific frequency band.

Finite Element Analysis of ASRS Racks - Stability Analysis:

Conduct stability analysis on the structure and calculate its stable critical load. Investigate the performance of the structure under five working conditions such as ultimate static load, X-direction and Y-direction horizontal forces, and X-direction and Y-direction earthquake actions.

Finite Element Analysis of ASRS Racks - Anchor Strength Calculation:

Establish a 1:1 high-precision solid model for the key components in the ASRS racks to analyze their deformation more accurately. The overall mesh model may not fully reflect the mechanical properties of the key components.

Through the above finite element analysis methods for ASRS racks, the critical loads of the structure's strength, stiffness, and stability can be determined, thus ensuring the safety of the project and the reliability of implementation.

Case 2 - Stress Analysis of Steel Storage Racks

Case Background:

In recent years, with the continuous development of the logistics industry, storage racks have been widely used in various factories and warehouses. The quality and service life of storage racks are directly related to the safety and efficiency of warehouses or factories. Therefore, it is very necessary to conduct quality assessment and design optimization for storage racks. This article aims to explore the strength, stability, and deformation of storage racks under different loads through finite element analysis to improve the use effect of storage racks.

Analysis Purpose:

Use finite element analysis to realize the structural and performance analysis of storage racks. By simulating the actual working conditions and local stress distribution under different loads, obtain the stress, deformation, displacement, and failure mode of the storage rack structure.

Execution Standard:

"GB/T 15234-2008 Design Standard for Storage Rack Structures"

1. Model Processing

Remove the interference, gaps, and irrelevant parts in the model to obtain the finite element calculation model.

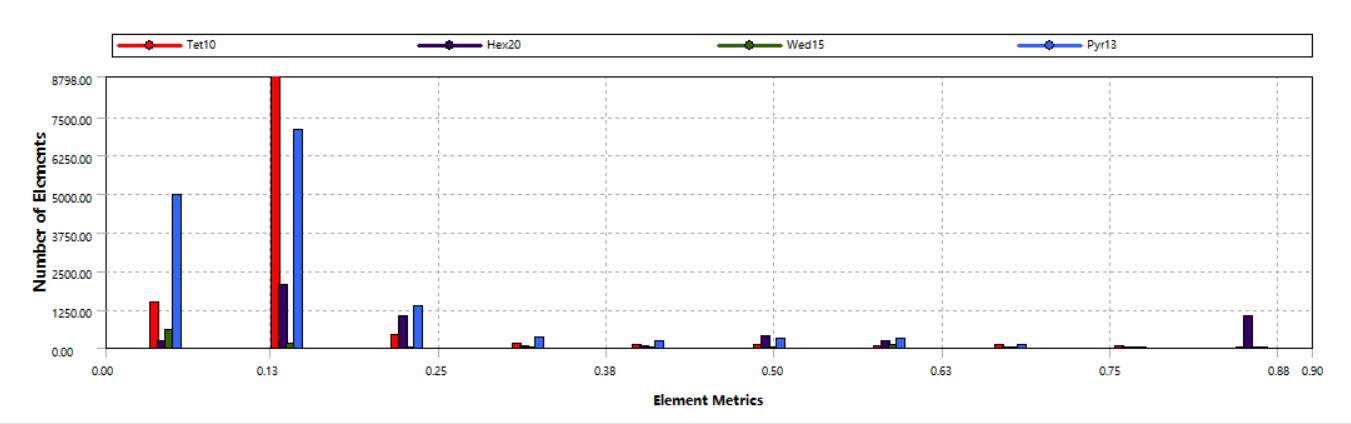

2. Mesh Generation

The mesh adopts a hexahedron-based division method. The main mesh size is set to 150mm, and the base mesh is set to 50mm. After division, there are 105,696 nodes and 31,283 elements.

After mesh generation, the mesh quality is above 0.77, reaching an excellent level, and the calculation accuracy is guaranteed.

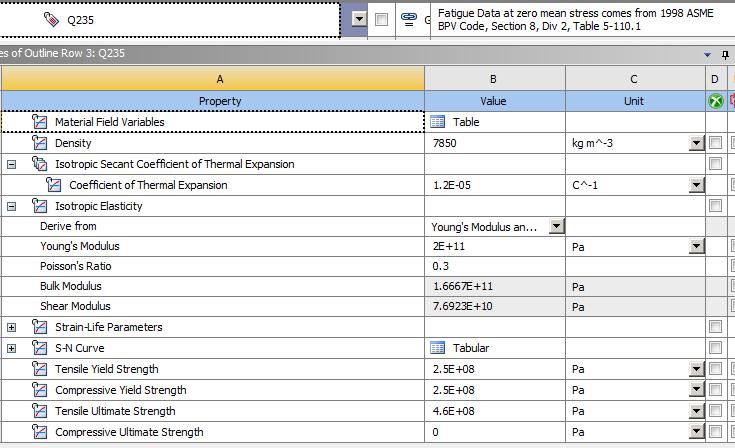

3. Material Selection

In this analysis, Q235 material is used in total, and linear calculation is adopted. The specific parameters are shown in the figure.

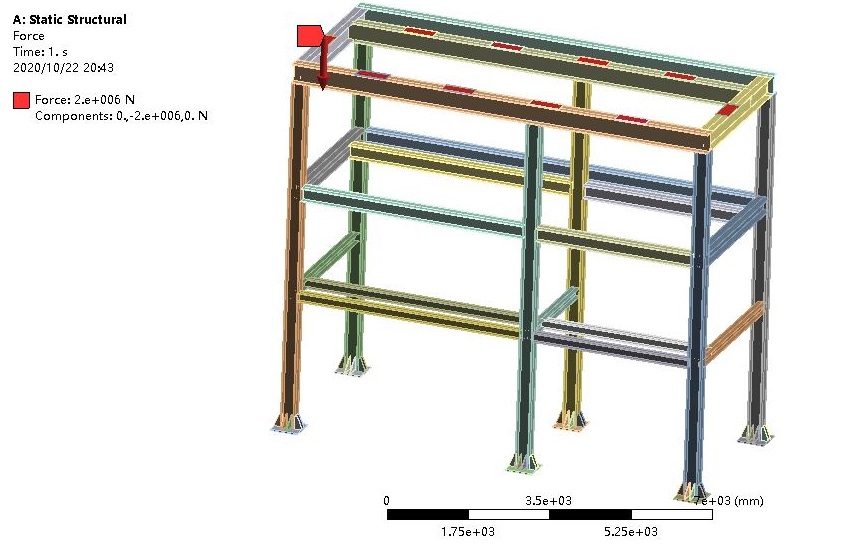

4. First Load Check

4.1 Load Addition

Add fixed constraints at the bottom hole and add a concentrated force load within the top force-bearing area. The load size is 200T.

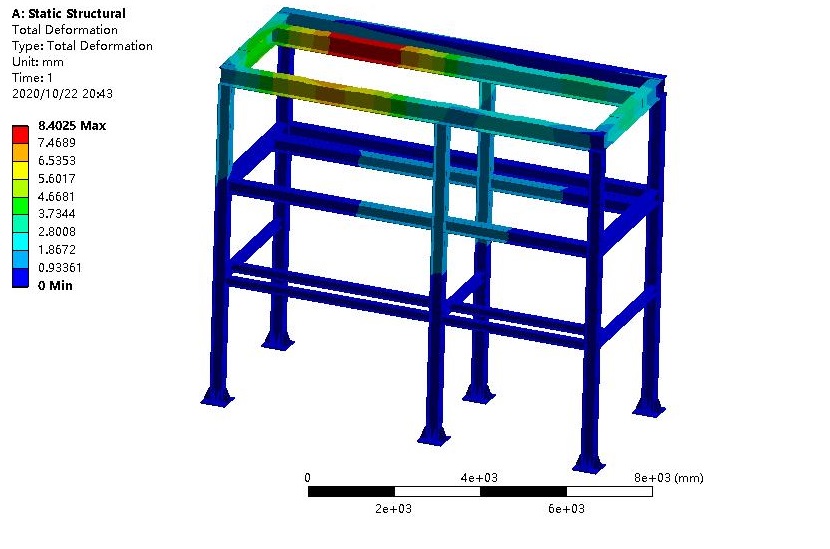

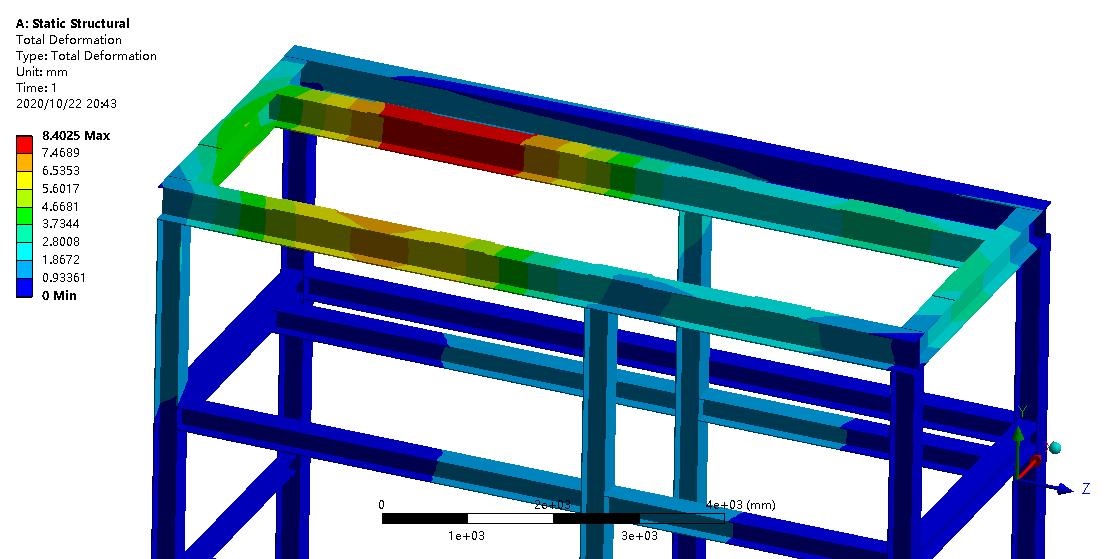

4.2 Deformation Calculation Results

After calculation, the maximum deformation reaches 8.4025mm, located at the center of the top, and the calculation meets the stiffness requirement.

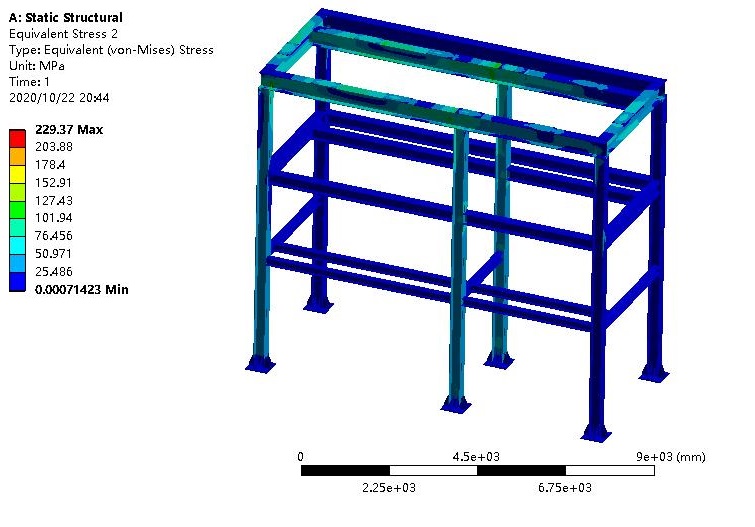

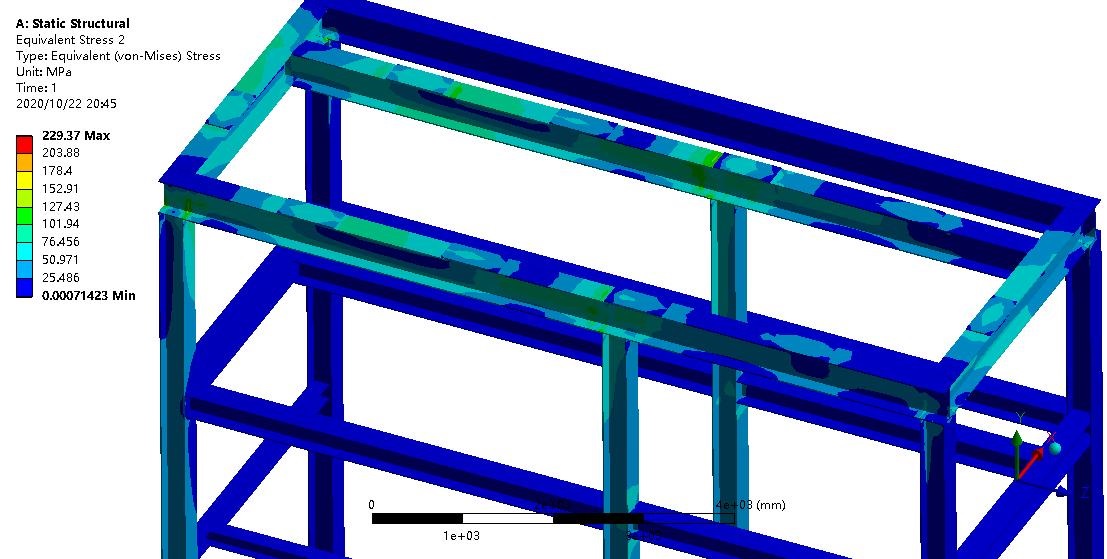

4.3 Stress Calculation Results

The maximum stress is 229.37MPa, which meets the strength requirement.

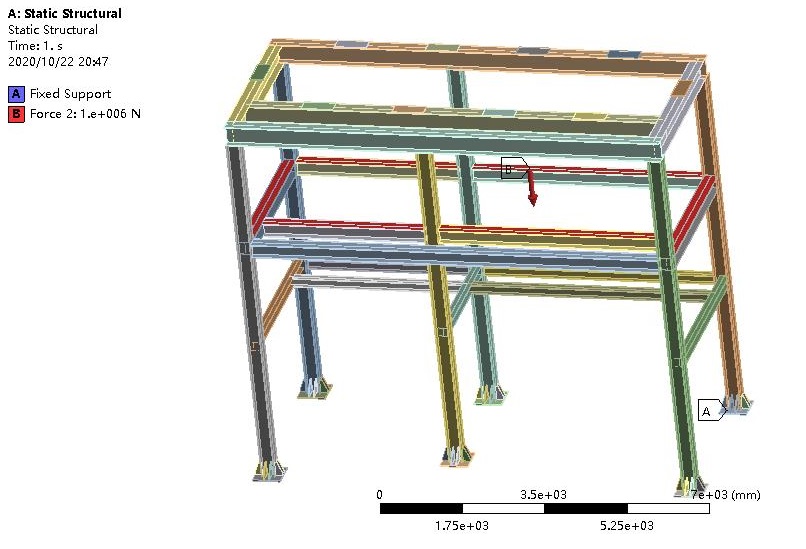

5. Second Load Check

5.1 Load Addition for Storage Rack Stress Analysis

Add fixed constraints at the bottom and add a concentrated force load within the top middle force-bearing area. The load size is 100T.

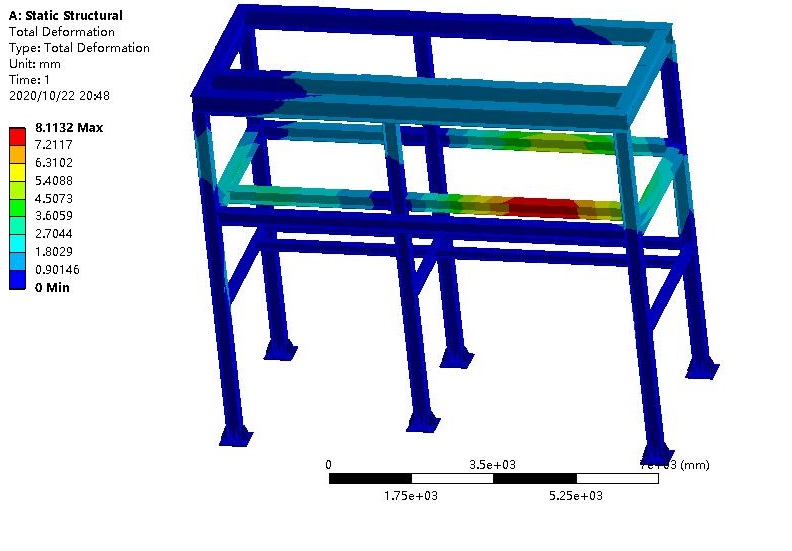

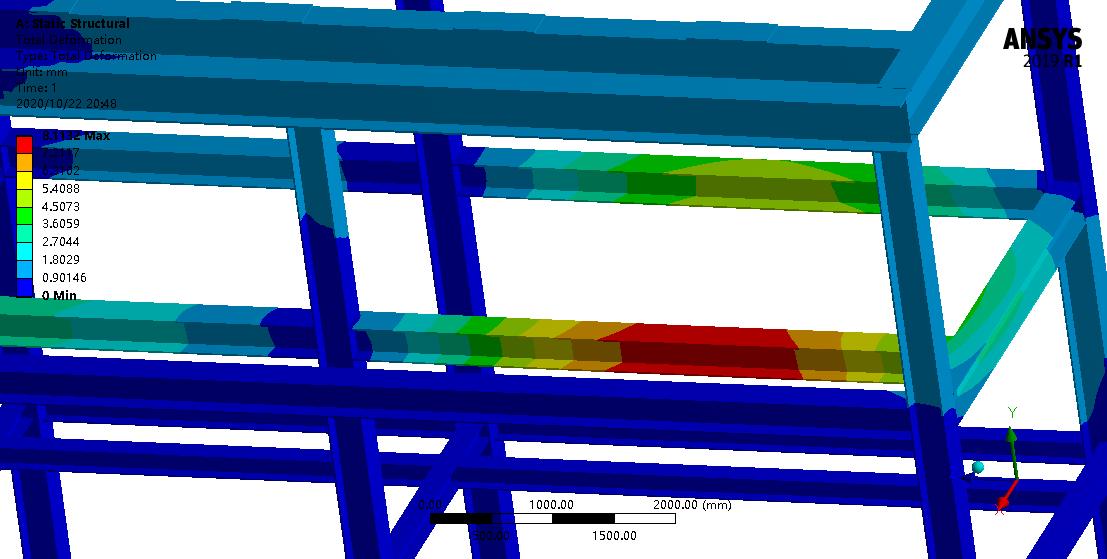

5.2 Deformation Calculation Results for Storage Rack Stress Analysis

After calculation, the maximum deformation reaches 8.1132mm, and the calculation meets the stiffness requirement.

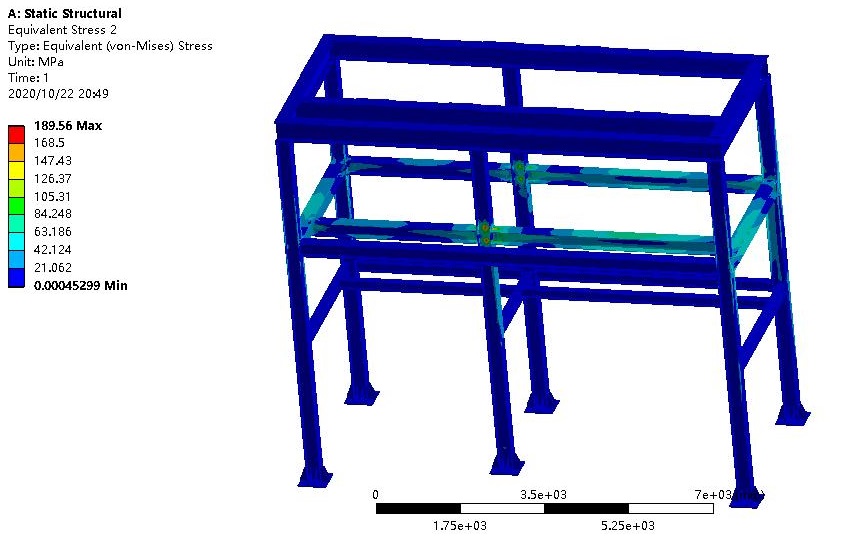

5.3 Stress Calculation Results for Storage Rack Stress Analysis

The maximum stress is 189.56MPa, which meets the strength requirement

Conclusion:

The results of the stress analysis of storage racks show that the stress conditions of storage racks are different under different loads, as shown in Figure 1. When the load gradually increases, the storage racks will be subjected to relatively large stress and are prone to buckling instability. When the load is small, the storage rack structure can bear a large amount of load without collapse and other phenomena.

Suggestions:

1. In order to ensure that the storage racks have good stability within the design range, it is necessary to conduct reasonable calculations and stress analysis on the storage racks.

2. Strengthen the design and reinforcement of the stress points and support points of the storage racks and ensure the overall stability of the storage racks.

3. When using storage racks, pay attention to the stacking and distribution of goods and do not exceed the design load of any storage rack.

4. During the installation, transportation, and maintenance of new storage racks, pay attention to the installation quality and fixing methods of the storage rack components to avoid deformation of the storage racks.

Disclaimer: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

View More Cases: Heat Dissipation Analysis Thermal Simulation Analysis Die Casting Mold Flow Analysis&

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice