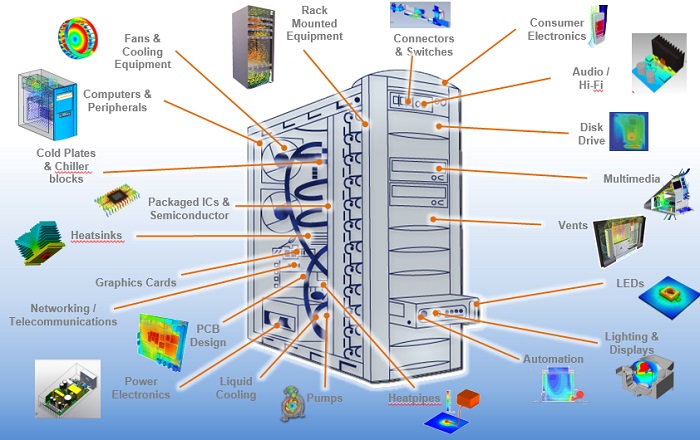

Electronic and electrical heat dissipation simulation analysis, solar thermal radiation analysis

Business Content:

Undertake thermal simulation analysis, heat transfer analysis, heat dissipation analysis, and solar thermal radiation analysis, involving industries such as chip semiconductors, electronic appliances, medical devices, and automobiles.

Application Value of Thermal Simulation Analysis:

What problems can be analyzed?

Heat Transfer Analysis: Conduct a comprehensive analysis of heat conduction, convection, and thermal radiation inside and outside the electronic system, and calculate the temperature field and flow field inside and outside the equipment.

Cooling Analysis: Analysis functions of natural cooling, forced cooling, and mixed cooling.

Transient Analysis: Use the information corresponding to the heat dissipation and time change to define the heat dissipation situation that changes with time. It can not only perform transient analysis of startup, shutdown, and failure, but also perform transient analysis under the conditions of changing power consumption and environmental changes.

Solar Radiation Analysis: Determine the incident angle and radiation intensity of the sun, calculate the shielding, absorption, reflection, transmission, and refraction of solar radiation, and consider the differences in the solar radiation absorption rate α and infrared emissivity ε respectively.

Liquid Cooling Analysis: Analyze the heat dissipation system containing multiple cooling media, such as the thermal analysis of electronic equipment or cold plates with both liquid cooling and air cooling.

Get to Know the Key Members of the Team

Industry Cases of Thermal Simulation Analysis:

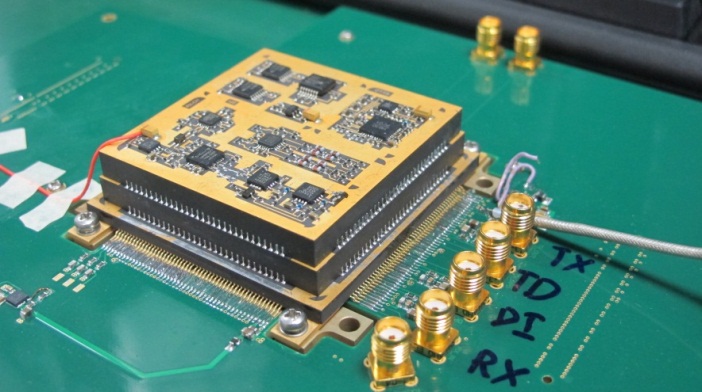

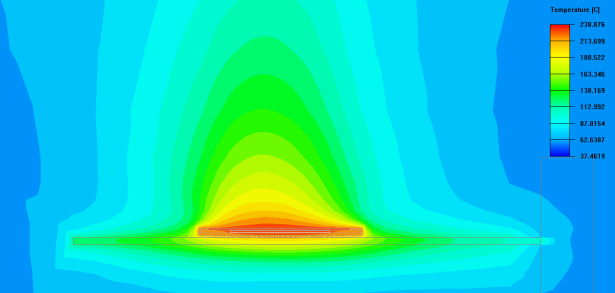

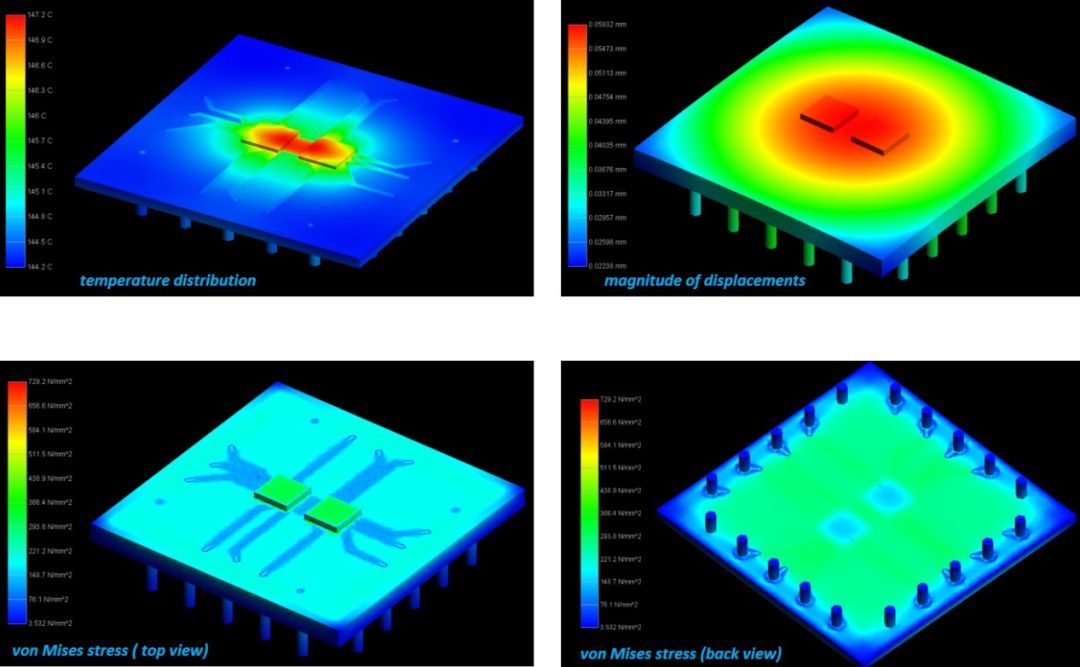

1. Thermal Simulation Analysis of Chip Packaging and Semiconductor Components

Packaging components composed of different materials will generate significant thermal stress in a temperature-changing environment, which may lead to packaging failure. Abaqus has powerful thermal-solid coupling analysis functions, including: steady-state heat conduction and transient heat conduction analysis, sequential coupling thermal-solid analysis, fully coupled thermal-solid analysis, forced convection and radiation analysis, thermal interface contact, thermoelectric coupling, etc.

Packaging Chip Thermal Simulation Analysis Temperature Distribution

Chip with Heat Sink Thermal Simulation Temperature Distribution

It can define complex material models, from simple elastoplastic models to thermoplastic, thermosetting, and high-temperature creep models with material constants that change with temperature, to simulate the thermal and mechanical properties of electronic materials such as metals, polymers, and composites.

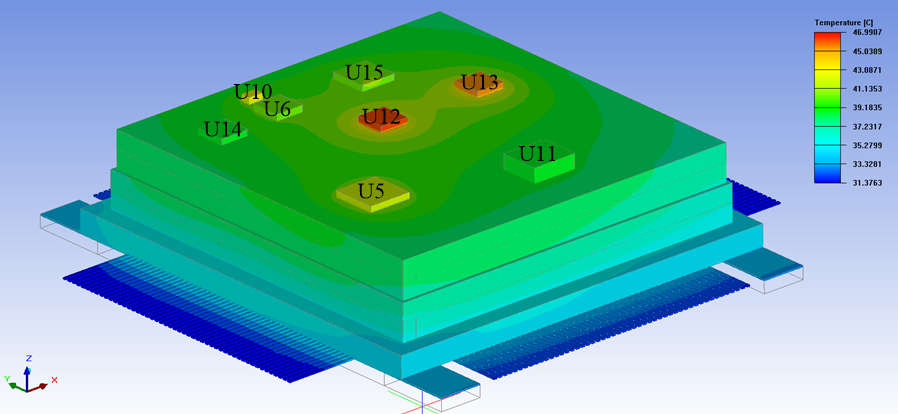

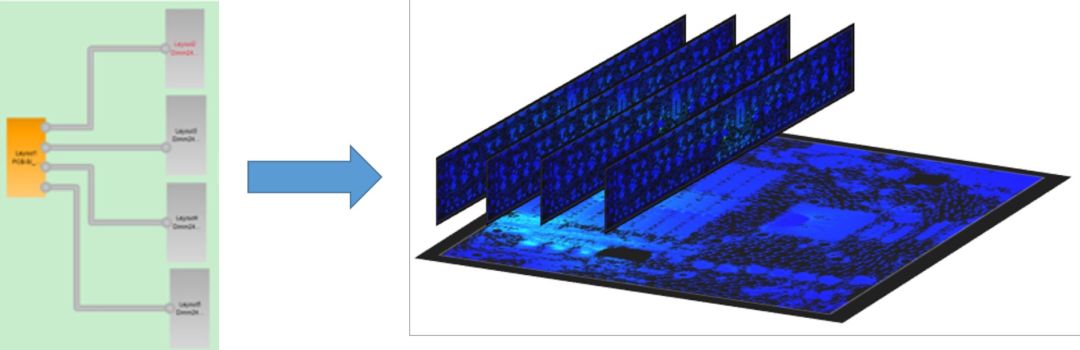

Temperature Distribution of PCB Board with Multiple Chip Packages in Thermal Simulation Analysis

PCB Board Thermal Stress Distribution

Nowadays, more and more packaging/PCB system designs require thermal analysis. Power consumption is a key issue in packaging/PCB system design, and the thermal and electrical domains need to be carefully considered. To better understand thermal analysis, we take heat conduction in solids as an example and utilize the duality of these two domains. Figure 1 and Table 1 describe the basic relationship between the electrical and thermal domains.

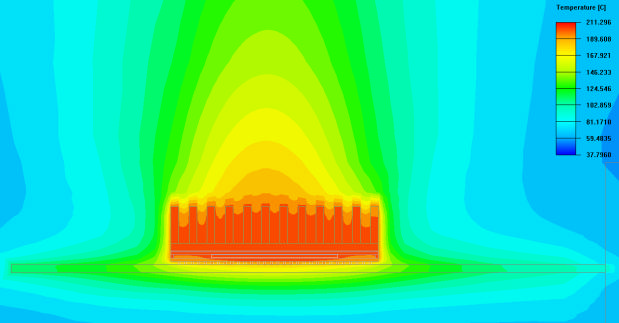

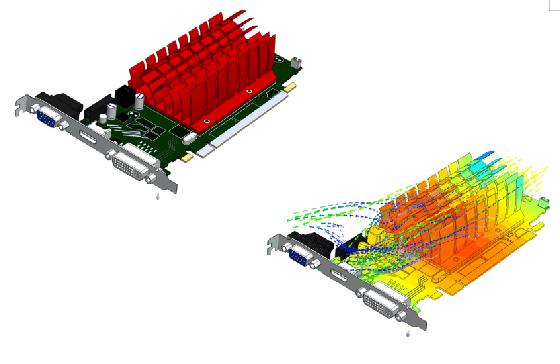

2. Thermal Simulation Analysis of Graphics Cards

The heat pipe radiator of the graphics card can effectively reduce the thermal resistance from the heat source to the radiator by adding heat pipes, thereby significantly improving the heat dissipation performance of the graphics card. The rapid development of electronic technology has triggered a revolution in the 20th century. Nowadays, the volume of electronic products has been greatly reduced, but the power consumption has increased. However, at the same time, the problem of overheating of the equipment has gradually become an important cause of electronic equipment failure. Therefore, in the design stage, how to use finite element simulation analysis software to optimize the product heat dissipation design to the greatest extent has become the top priority in the design of electronic products.

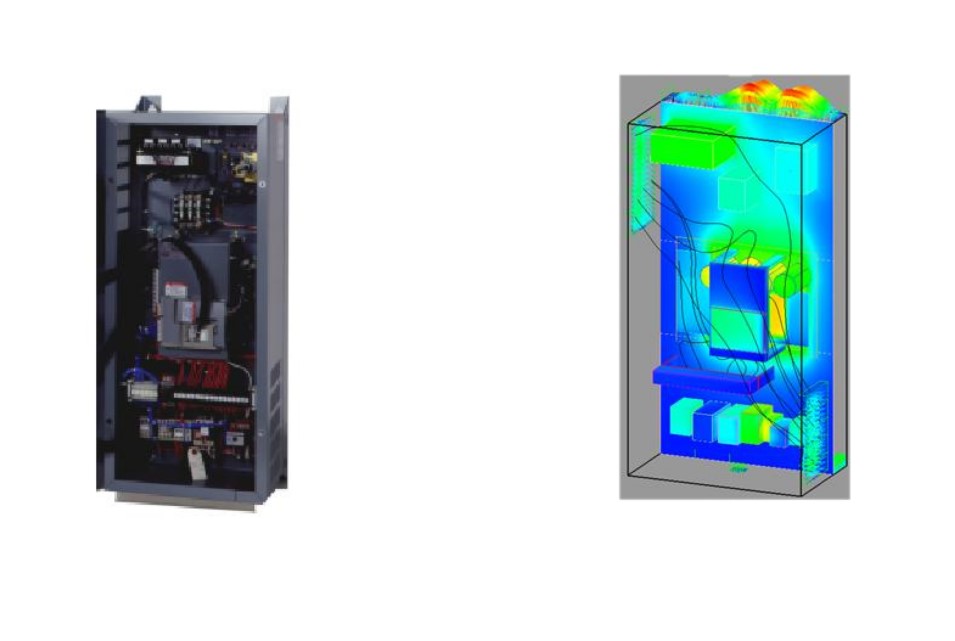

3. Thermal Simulation Analysis of Data Centers and Electrical Cabinets

By adjusting the structure, optimizing the heat dissipation path, and adding heat pipe radiators, the operating temperature of the electrical equipment in the cabinet can be effectively reduced. At the same time, the thermal environment and the temperature values of each module in the electrical cabinet are determined by calculation, and the heat dissipation performance of the cabinet and the module layout are optimized.

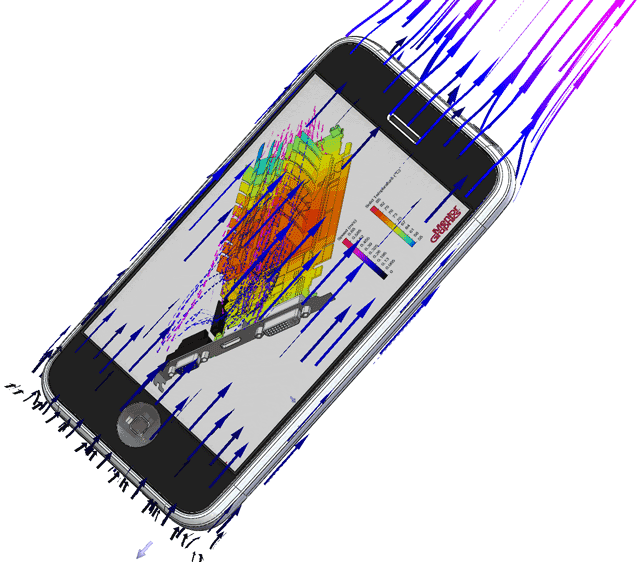

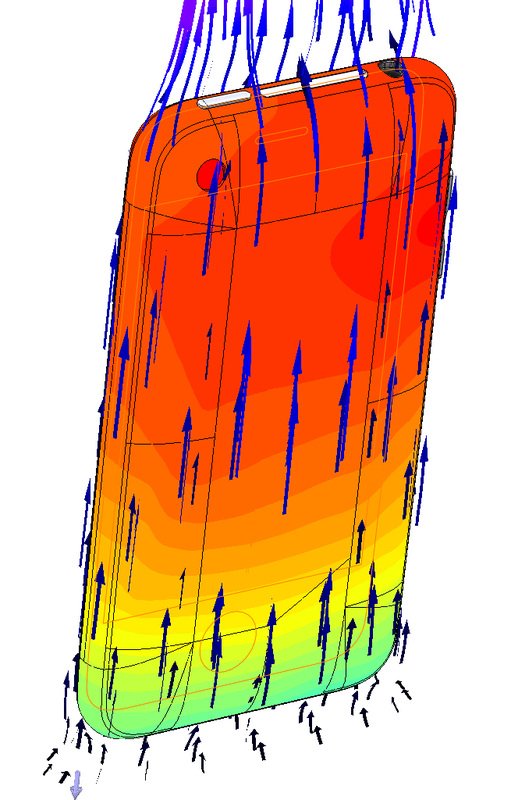

4. Heat Flow Analysis of a Mobile Phone

Currently, high-end manufacturers in the electronic and electrical industry have very high requirements for product reliability, with long life cycles and high development costs. There is a strong demand for CAE in the process of development and failure analysis. At present, the CAE analysis capabilities of domestic enterprises in the industry are not yet high. Electronic and electrical products are civilian daily consumables, featuring short life cycles, large product volumes, limited design space, high precision, and great difficulty in optimization.

The reason why some products have much better heat dissipation performance than those with the same chip models is closely related to the design of the heat dissipation system. With performance improved, the heat dissipation system plays a key role. The liquid cooling heat dissipation system covers the main heat source areas of mobile phones such as chips and motherboards, enabling them to always remain within a reasonable temperature range.

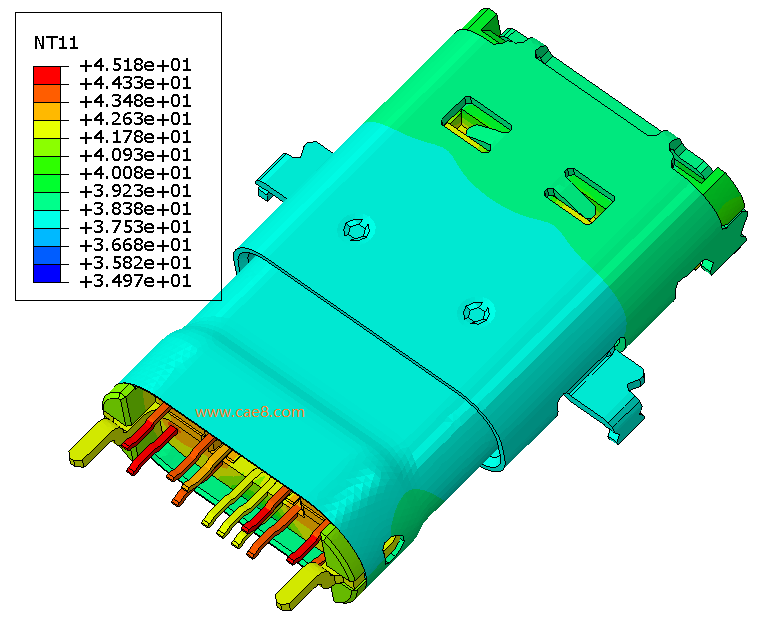

5. Thermal Simulation Analysis of Connector Terminals

There are a wide variety of electronic devices and complex usage environments. Especially for electronic devices used in the defense field that need to withstand harsh environments, they not only need to be resistant to salt spray, moisture, and vibration, but also need to be small in size, light in weight, and have good heat dissipation performance. Therefore, electronic devices that can withstand harsh environments usually adopt a fully enclosed structure, and the problem of overheating of components in electronic devices is more prominent than that of electronic devices used in the industrial field.

The relevant technologies for solving the problem of overheating of electronic devices to improve product reliability are called electronic device heat dissipation technologies, including thermal design, thermal simulation, and thermal testing. They are indispensable technical means for discovering and solving thermal defects of electronic devices and improving product reliability. By integrating and applying thermal design, thermal simulation, and thermal testing technologies in parallel in the development of electronic products, the product development cycle can be greatly shortened, product reliability can be improved, and the comprehensive performance of electronic products can be ensured.

Charging Standards:

Quotations are calculated based on the difficulty of specific projects. Due to the wide range involved in heat dissipation simulation, differences in projects, and variations in test items, as well as differences in the types of finite element analysis and their difficulty coefficients, it is impossible to unify the prices of standard projects. Guided by customer needs, the most suitable product solutions will be formulated and recommended for each customer. Emphasize integrity, prioritize quality, serve wholeheartedly, and win trust.

Contact for Consultation, Explore Scientific Casting Solutions, and Create Higher Added Value Together

Manager Xu, Tel: 199 4191 2022. Letu Zhizao Technology, providing finite element analysis engineering services, software sales, and scientific numerical technology solutions.

Declaration: This article is originally created on the official website of Letu Zhizao. Please indicate the source when reprinting.

View More Cases:Heat Dissipation Analysis Thermal Simulation Analysis EMC Simulation CFD Simulation CFD Analysis Electromagnetic Field Simulation Analysis Fatigue Analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice