FEM analysis of die, thermal stress fatigue analysis of die

Business Content:

Plastic, die casting mold FEM analysis, mold structural strength optimization, mold program development, product research and development end cae analysis, mold molding end finite element analysis engineering services, manufacturing problem solving and improvement, finite element analysis software sales

Mold FEM analysis application value:

The traditional way of guessing by experience has been unable to keep up with the international situation, and the production side of "design, processing, assembly, test mold, repair mold, and N re-test molds" is characterized by low precision, short life, long design and manufacturing cycle, and higher cost, which seriously weakens the competitiveness of China's high-end molds in the international market.

Let's take a look at the application practice of Leto using finite element analysis technology in mold manufacturing and how to improve the service life of the mold.

Mold FEM analysis Case:

Mold structural strength analysis 1: Problem: Mold fatigue cracking (inner mold cracking)

It can be seen from the figure above that there is a local cracking problem in the mold. During the injection molding process, the mold often fails to reach the design life. For example, the preset life of the production is 300,000 times, and the actual situation is 200,000 times. This is a classic fatigue failure problem. This directly causes the mold to be unusable. It seriously affects the service life of the whole mold, increases the use and maintenance cost of the mold, and greatly reduces the production efficiency of the product manufacturer, so it is of great significance to study how to improve the strength of the mold parts.

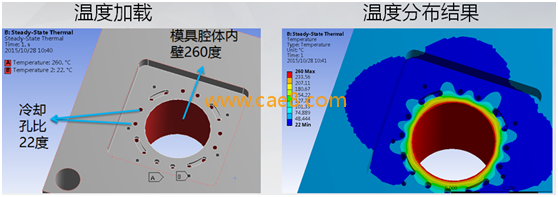

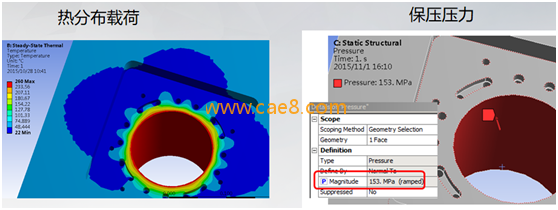

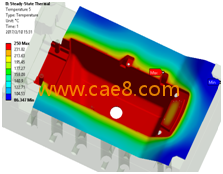

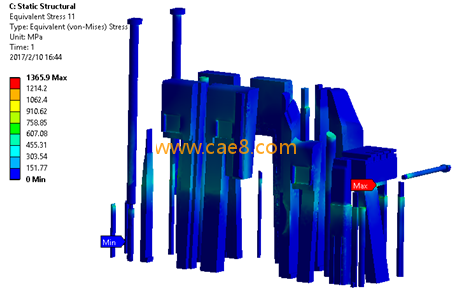

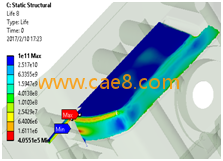

Finite element simulation analysis results, heat transfer analysis:

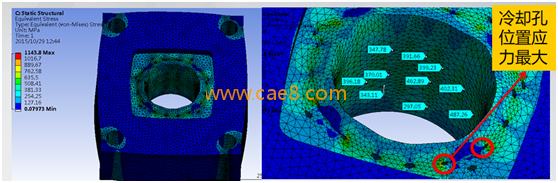

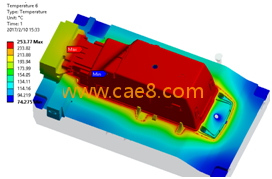

Thermostructural coupling analysis results:

The internal wall stress of the cavity is basically about 400MPa, and the local opening position stress is 1144MPa. The ultimate strength of the material "Cr-Mosteel SAE4142_400_QT" is 1550MPa, so the static strength of the cavity meets the requirements!

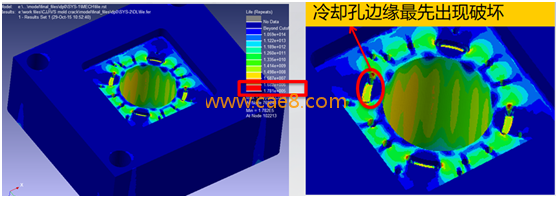

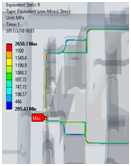

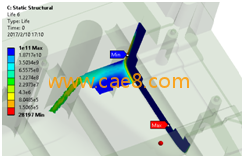

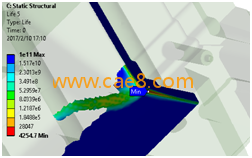

Fatigue analysis result

Cavity wall fatigue can meet the requirements theoretically. However, after 178,100 times of use, fatigue damage occurs first at the position of the cooling hole, and then the damage develops along the direction of the opening hole, resulting in fatigue damage to the entire inner wall of the cavity.

Conclusion:

1. The static strength of the mold cavity meets the requirements.

2. The mold cavity was first damaged at the position of the cooling hole, and later developed to the entire cavity wall.

3. In the fatigue analysis, it is found that when the pressure is set as a variable, the strength and fatigue will get different results. When the pressure is 130MPa, the life is 327,700 times, and the fatigue is mainly caused by too high pressure holding.

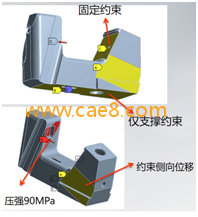

Mold structural strength analysis 2:

Thermal stress analysis content:

1) Mold temperature analysis: detailed temperature distribution of the front and back molds

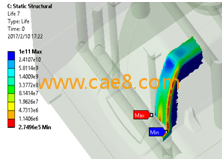

2) Stress nephogram of main parts of the master die: the stress is larger at the four corners of the inner cavity of the master die, and the maximum stress is 1718.5MPa. The four corners are more dangerous, and there is a risk of damage.

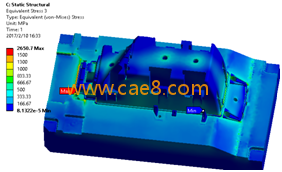

3) Stress cloud diagram of the main parts of the mold: the stress in the edge slot of the mold is large, the maximum stress is 2650MPa, and there is a risk of damage.

4) Stress cloud map of other components: the local stress concentration of other ejecting mechanisms, the maximum stress is 1366Mpa

5) The fatigue life cloud of one side of the inner cavity of the master die: the side is more dangerous, and the minimum life is 4254 times. Risk of fatigue damage.

The fatigue life cloud of the other side of the inner cavity of the master die: the minimum life of this side is 275,000 times.

6) Fatigue life cloud of the male mold: the fatigue life of the inner groove around the male mold is relatively low, and there is a risk of fatigue damage.

Sum up

1. Find out the dangerous area of the mold structure through simulation.

2. The fatigue life of the two dangerous areas is 4254 times and 27.5w times respectively.

3. Suggestions for structural optimization:

It is recommended to reduce the hole size or round the corner in the dangerous area.

The shape of the contact surface is optimized to reduce local stress concentration.

4. Process optimization suggestions: High stress amplitude is often the main cause of fatigue failure, so reducing the peak pressure during injection molding can effectively improve the life of the mold structure.

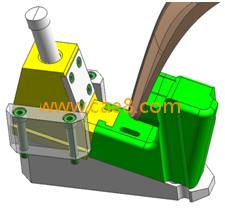

Die structural strength analysis application case 3- (slider deformation and fracture) :

Problem: In the actual production, the slider is deformed during the forming process, which affects the size of the product buckle, and finally the inner slider is broken, and the mold structure is modified in a wide range.

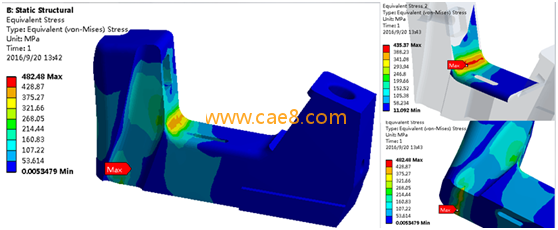

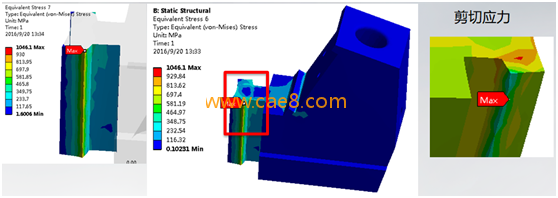

Finite element analysis results of the original scheme:

The maximum stress of the mold appears at the buckle, and the maximum stress is 1046MPA> the yield limit of the material 1000MPa, which does not meet the requirements.

Finite element analysis results of the original scheme - internal buckle

The maximum stress appears in the internal buckle, and the maximum stress is 1046MPA> the yield limit of the material 1000MPa, which does not meet the requirements.

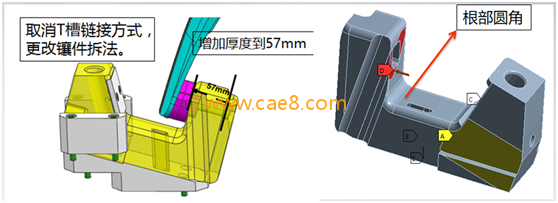

Optimization suggestions: Improve the mold structure as shown below.

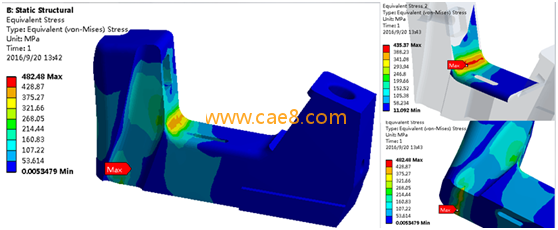

优化方案有限元分析结果:

改进后的模型最大应力值为482.48MPa,安全系数:1000/482.48=2.07,符合要求。改进后的模具在使用过程中再没有出现问题。

In our country, the mold industry is known as the "mother of industry". With the rapid growth of industrial production, it has become a high-tech industry supported by the state. Relying on the traditional method of experience guessing "design, processing, assembly, mold repair, mold repair, and mold trial" to design and manufacture molds. Compared with foreign advanced developed countries, domestic molds show the disadvantages of low precision, short life, long design and manufacturing cycle, and high cost, which seriously weakens the competitiveness of high-end molds in our country in the international market.

Due to the extremely complex working conditions, the entire mold is subjected to clamping force in the clamping state, and the strong prestress will cause pre-deformation of other structural inserts such as the die base and row position. These deformations will wrap the oblique push rod in the template chute where the oblique push rod plays a guiding role. During the working process, the mold temperature is high and the change range is large, which will also cause internal thermal stress on the oblique push rod. Poor lubrication will increase the friction between the oblique push rod and the guide chute, which is not conducive to the oblique push rod being successfully pushed out to complete the core pulling movement. Due to factors such as manufacturing, processing, and assembly, the movement of the oblique push rod in the guide chute will also be blocked. Once the oblique push rod movement is blocked, the wear and ablation of the oblique push rod will be accelerated, and the phenomenon of bending or even breaking will occur, which will seriously affect the service life of the whole mold, increase the maintenance cost of the mold, and greatly reduce the production efficiency of the product manufacturer. Therefore, it is of great significance to study how to improve the strength of the mold mechanism.

FEM analysis fee standard:

Calculate the quotation according to the specific technical requirements. Due to the differences in mold structure and test items, involving the types of finite element analysis and the differences in their difficulty coefficients, it is impossible to unify the price of standard items. Guided by customer needs, we will develop and recommend the most suitable product plan for each customer. Integrity first, quality first, dedicated service, to win trust.

Contact for consultation, explore scientific and intelligent manufacturing solutions, and create higher added value together

Letu Intelligent Manufacturing Technology, manufacturing solution development, finite element analysis engineering services, software sales, providing scientific numerical information technology solutions for the manufacturing industry,

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice