Simulation and analysis of thermal runaway directional detonation smoke of battery pack

Business Content:

Thermal management engineering consulting: Thermal management development analysis such as thermal analysis of new energy battery packs, thermal analysis of electronic components, and solar radiation analysis.

Application Value of Thermal Runaway Management:

Thermal runaway of battery packs is a technical barrier for new energy vehicles:

New energy vehicle models are becoming mainstream. Currently, there are still problems such as high manufacturing costs, limited driving range, long charging time, and residual value. The thermal stability of high-nickel batteries largely determines the success or failure of the performance of new energy vehicles. As the nickel content increases, the stability of the cathode material decreases, resulting in an increased risk of battery spontaneous combustion caused by thermal runaway.

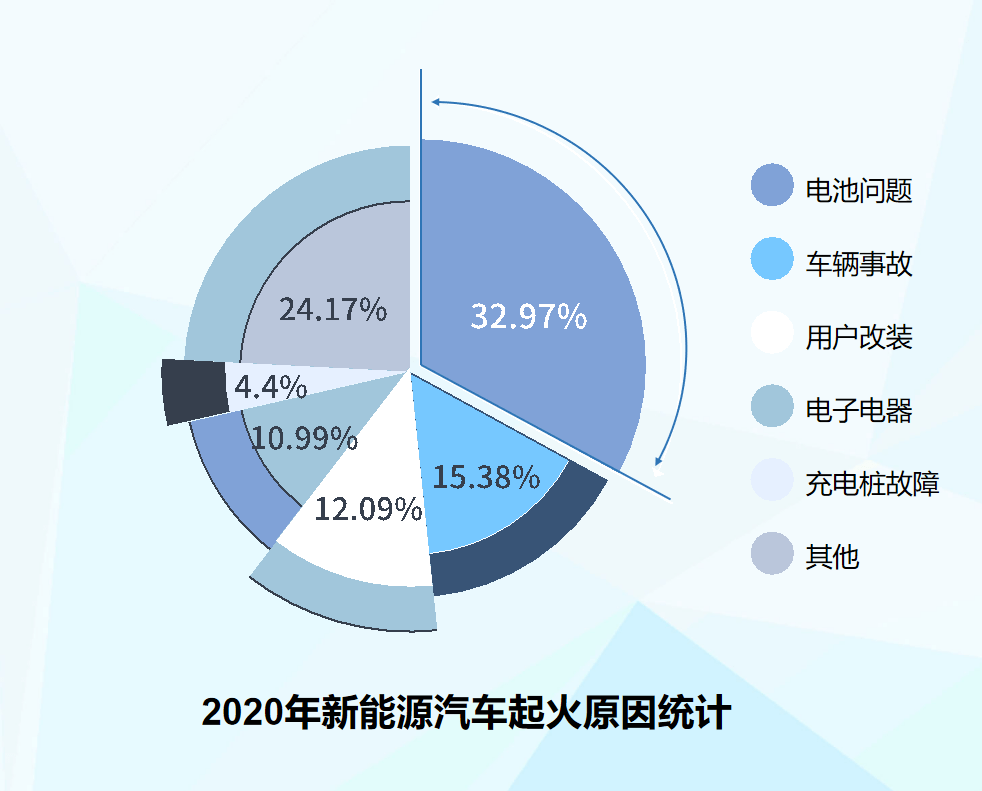

The problem of thermal runaway of battery packs has become the main cause of accidents in new energy vehicles.

Data shows that in the accidents of new energy vehicles in China in 2020, accidents caused by battery problems accounted for the majority, and among them, the problem of thermal runaway became the main cause.

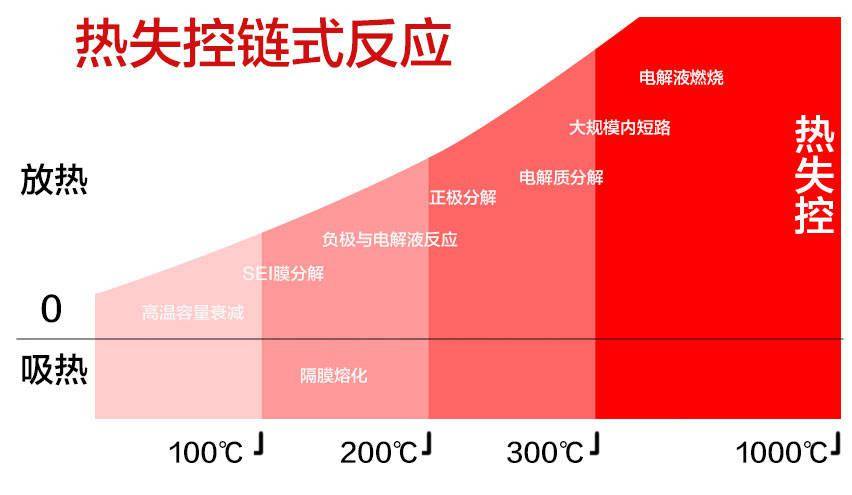

During the discharging process of the battery, the "side effect" it generates is heat release. If the heat dissipation conditions are poor, the "side effect" of heat release may cause the temperature to exceed the standard. When the battery reaches 450 °C, it will cause the electrolyte to burn, thus triggering thermal runaway. When a single battery cell experiences thermal runaway, the adjacent cells will also experience thermal runaway one after another under the influence, resulting in a chain reaction caused by the spread of thermal runaway and then leading to safety accidents.

To solve the problem of thermal runaway, finite element analysis plays a crucial role.

Objectives to be achieved:

In order to improve the competitiveness of electric vehicles compared with traditional fuel vehicles, the energy density of the equipped batteries is moving towards more than 350 Wh/kg, and the driving range on a single charge exceeds 800 km. To a large extent, this depends on the design scheme of high-nickel battery packs.

The development of power batteries can be divided into pack design, module design, cell design, and material design. It requires the joint cooperation of engineers in various specialties such as mechanical, electrical, software, simulation, materials, and chemistry to design the final product for delivery and use in the whole vehicle. Therefore, the investment in human resources and test costs in the early stage is very large, and the entire development cycle is also very long. Theoretical simulation can solve this problem well, shorten the R & D cycle, and provide a powerful theoretical basis for scheme evaluation.

Effectively simulate the thermal distribution of battery packs.

When a single battery cell experiences thermal runaway, the adjacent cells will also experience thermal runaway one after another under the influence, resulting in a chain reaction caused by the spread of thermal runaway and then leading to safety accidents. Finite element analysis can effectively predict the heat release of battery packs, clarify the maximum temperature value of the modules, and the distribution of high and low temperatures. Designers need to control them within the allowable temperature range.

Simulation analysis of the smoke flow direction in the directional explosion-proof of thermal runaway.

The design of the heat source barrier will block the batteries or the entire battery pack that may cause combustion and explosion due to thermal runaway in a predetermined space, and guide the released flame heat flow to the explosion-proof outlet for release through the predetermined route. In this process, the directional explosion-proof technology can quickly reduce the high-temperature gas exceeding 1000 °C to within 200 °C, and then quickly disperse it so that the temperature of the gas discharged outside the battery pack is lower than 100 °C.

Based on the temperature situation of the simulation results of the thermal analysis of the battery pack, if the temperature rise cannot be avoided, it is necessary to control it within a certain range at the early stage when it is about to break out. Designers have carefully designed a heat source barrier system for it: a "firewall" established between cells.

Simulation analysis of the fire flow temperature in the directional explosion-proof of thermal runaway.

The high-temperature gas ejected through the directional explosion-proof outlet was effectively suppressed within less than 3 seconds, and the overall temperature was also reduced to below 100 °C.

In the application of this project, a pack-level thermal runaway combustion model was adopted to achieve multi-dimensional explosion-proof analysis and fitting simulation of air flow and fire flow, realizing the function verification of the design model built entirely through virtual digital simulation without actual sample testing, overturning the traditional development method of developing first and then testing.

Declaration: This article is originally created on the official website of Letu Zhizao. Please indicate the source when reprinting.

View More Cases: Die Casting Mold Flow Analysis Modal Analysis Drop Test Analysis Fatigue Analysis CFD Analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice