Friction thermal stress analysis of brake disc

Business Content:

Finite element analysis consultation on thermal management, design scheme development, and software sales in industries such as electronic appliances, medical devices, and automobiles.

Application Value of Thermal Stress Analysis:

1. Improve the driving safety of automobiles. The braking system is an important part of automobiles. The braking process of disc brakes is a typical thermo-mechanical coupling process. The distribution and changes of its temperature field and stress field will have a direct impact on the working performance and service life of the brakes, which is an important consideration in the design and research and development of automobile brakes.

2. Improve the driving comfort of automobiles. The squealing sound during automobile braking will harm people's physical and mental health. Studying the vibration characteristics of brake discs plays an important role in controlling the squealing sound.

Thermal Stress Analysis Industry Cases:

Simulation Background of Thermal Stress Analysis

Frictional heat exists in almost all engineering practices. Heat generation due to friction is a common problem encountered in engineering practices. However, the problems involved are not simply thermal analysis but the combined effect of multiple physical fields. The thermal stress analysis of brake discs involves the thermal stress coupling problem of temperature field and stress field. During the analysis process of the problem, the effect of each physical field and the influence among them need to be considered simultaneously.

Thermal Conduction Analysis of Brake Discs - Temperature Distribution Results

Brief Introduction to the Results of Thermal Conduction Analysis of Brake Discs:

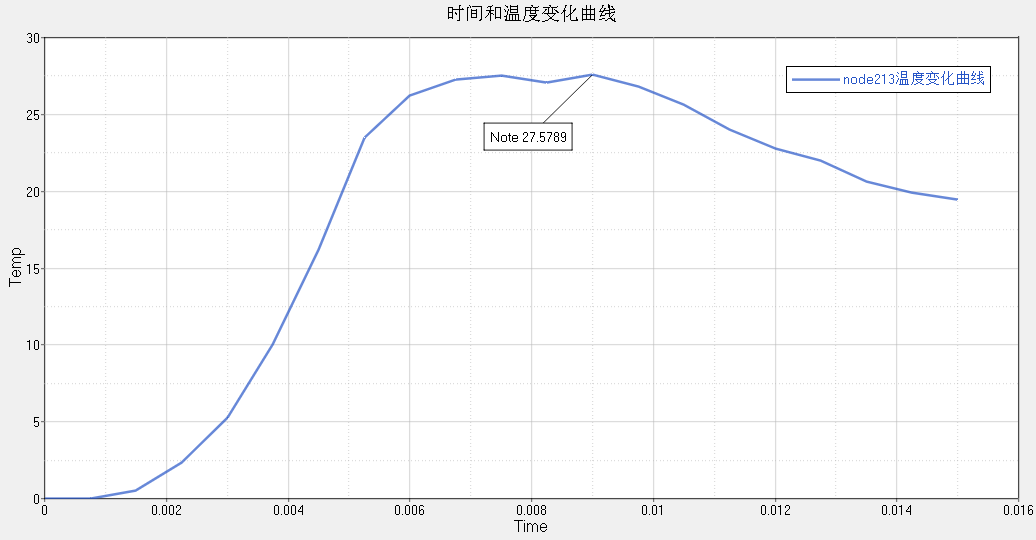

As can be seen from the figure, with the passage of time, the brake disc generally experiences a process of first heating up and then cooling down, which is caused by the gradual reduction of the rotational speed of the brake disc. The temperature field on the brake disc is not axisymmetrically distributed. At different points in the circumferential direction on the same radius, due to the different times of contact with the friction lining, there is a time difference in the temperature fluctuation. There is also a relatively large temperature gradient along the radial direction of the brake disc. On the same radius direction, as the radius increases, the temperature on the disc surface first increases and then decreases. In addition, the temperature on the friction surface of the brake disc is higher than that inside the material because the rate of frictional heat generation during the operation of the brake is higher than the rate of heat conduction inside the material. Since the inner diameter of the brake disc is far from the friction area, the frictional heat generated is difficult to be transferred to its vicinity in a short time, so the temperature rise at the inner diameter of the brake disc is very small.

The braking device is an indispensable and important component system for any motor vehicle. The quality of the braking system is directly related to people's lives and property safety. Brake discs are widely used in the braking systems of motor vehicles. When a motor vehicle brakes, the kinetic energy of the vehicle is converted into thermal energy generated by the friction between the brake pads and the brake discs. Most of the generated thermal energy will be absorbed by the brake discs in a short time, resulting in a sharp increase in the temperature of the brake discs and relatively large thermal stress. Meanwhile, the high temperature caused by the heat generated by the brake discs will have a great impact on the material properties and braking performance of the brake pads, which will lead to safety problems in the braking system.

Thermal Conduction Analysis of Brake Discs - Thermal Stress Distribution Results

During the braking process of a motor vehicle, a large amount of heat will be generated due to the friction between the brake pads and the brake discs. The generated heat will have a great impact on the material properties and braking performance of the brake pads. In this example, we take this as an example to analyze the thermal stress during the braking process. Through the thermo-mechanical coupling analysis of Abaqus, the distribution of the temperature field, stress field, and thermal deformation of the brake disc and the friction plate are obtained.

Charging Standards for Thermal Stress Analysis:

The quotation is calculated according to the difficulty of specific projects. Since CAE analysis covers a wide range, there are differences in engineering and various test projects, and there are differences in the types of finite element analysis and their difficulty coefficients, so it is impossible to unify the prices of standard projects. Guided by customer needs, the most suitable product solutions are formulated and recommended for each customer. Integrity is emphasized, quality comes first, and we serve wholeheartedly to win trust.

Declaration: This article is originally created on the official website of Letu Zhizao. Please indicate the source when reprinting.

View More Cases: Modal Analysis CFD Analysis Electromagnetic Field Simulation Analysis Die Casting Mold Flow Analysis Drop Test Analysis Fatigue Analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice