Finite Element Simulation Analysis of Drop Simulation

Undertake drop simulation analysis and testing for various industries. We are a professional finite element analysis company. 199 4191 2022

3C Products

Drop analysis of mobile phones, drop of home appliances, drop of computers, servers, drop of display screens, drop with packaging / protective cases, drop of PCB boards, drop of mice, drop of cameras, drop of smart watches

Aerospace

Crash of helicopters / unmanned aerial vehicles, forced landing of aircraft on land / water, recovery of satellites on land / water, parachute simulation, simulation of airdrop process, bird strike analysis,

Transportation

Drop analysis of battery packs, drop of BMS, collision of the A-pillar of commercial vehicles, ship entry into water, slamming of sea waves, container cargo

Homeland Security

Penetration and explosion simulation, drop of nuclear fuel containers, impact resistance of nuclear power facilities,

Medical Devices

Drop of medical equipment, drop of special tools, design of protective nets, protective helmets

Get to Know the Backbone of the Team

Application Value of Drop Simulation Experiments:

Drop analysis is about checking the strength, stiffness and stability of structural components when they impact different material surfaces at different heights and speeds.

Regarding the impact strength of structures, the strength of key structural components, connection reliability and failure analysis, simulation can be used to calculate the stress and strain during the process of the whole machine dropping at different angles, so as to evaluate the failure risk of components.

CAE analysis technology can not only optimize structures and improve product quality, but also greatly reduce the number of tests and lower testing costs.

Drop Analysis Cases (Only Part of the Content is Displayed):

☑️ Drop analysis of the whole machine with packaging ☑️ Drop analysis of the bare machine ☑️ Palletizing drop analysis ☑️ Collision analysis in usage scenarios

Case 1: Drop Simulation of Laptop Computers

The drop of a laptop computer generates a non-linear and complex dynamic response due to violent collision and dynamic load in an extremely short time. This belongs to a transient dynamic process. Structural dynamics is used to calculate the structure when the load changes over time. The velocity, acceleration, displacement and force of the structure can all change over time. This case is about the simulation analysis process of the corner drop of a laptop computer.

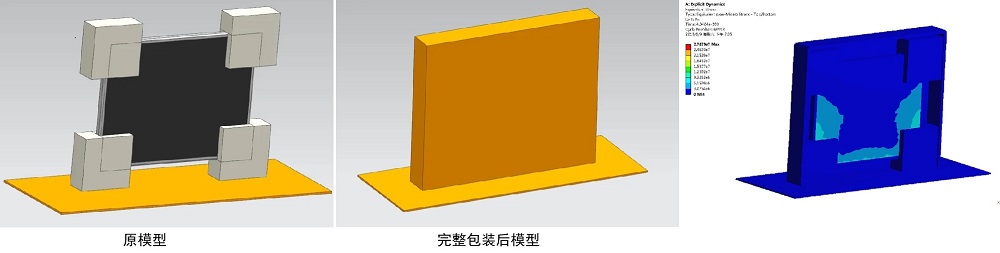

Case 2: Drop Simulation of Television Sets (Packaging Cushioning Foam Material)

With the rapid development of the global electronics industry, the design of electronic products is becoming more and more refined and complex. Market competition requires that electronic products not only greatly improve their performance indicators but also become increasingly miniaturized. CAE simulation has a wide range of applications in the electronics industry, such as the drop of electronic products, the research and development and manufacturing of new electronic materials, and the design and evaluation of the sound field characteristics of audio equipment.

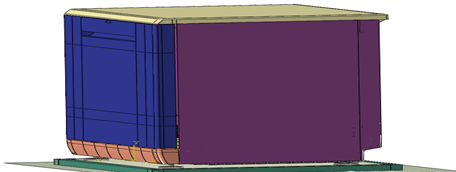

Case 3: Introduction to the Dishwasher Drop Analysis Model

The following diagram shows a CAE three-dimensional model, and the parts indicated in the figure are several components mainly focused on in the simulation:

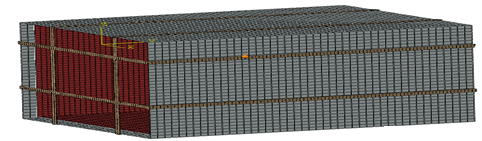

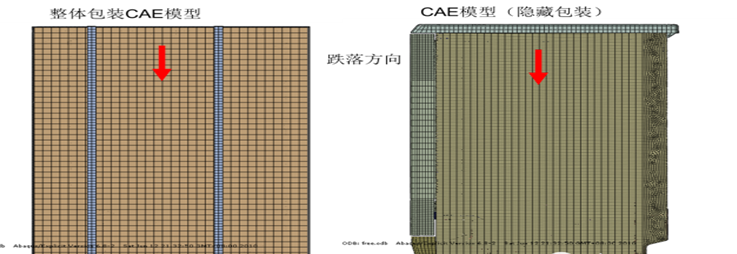

Mesh of the Drop Analysis Simulation Model:

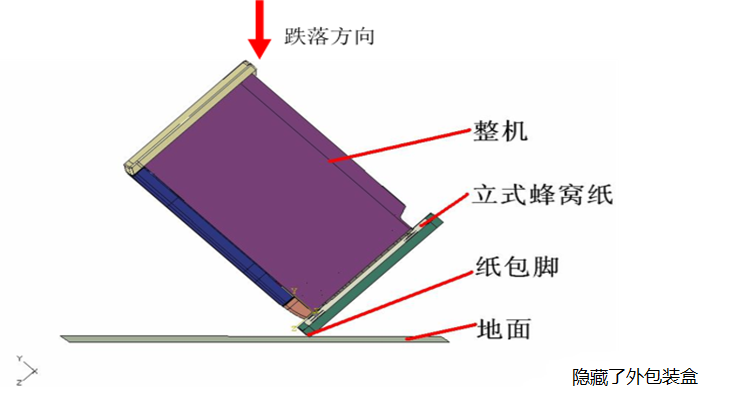

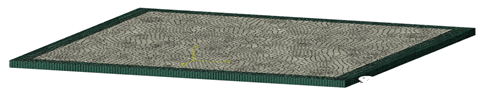

The following are the simulation models of the paper corner protector and the bottom packaging material:

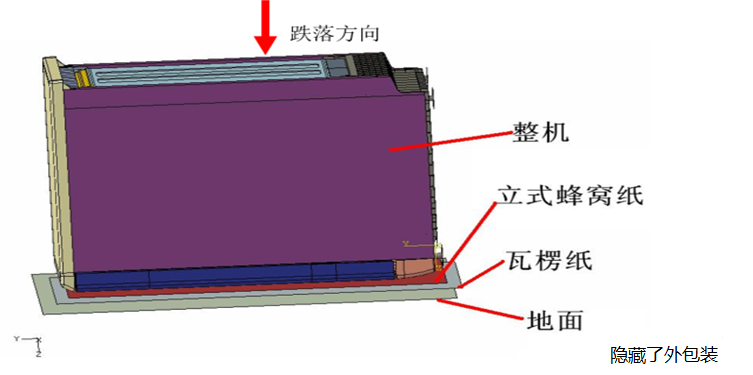

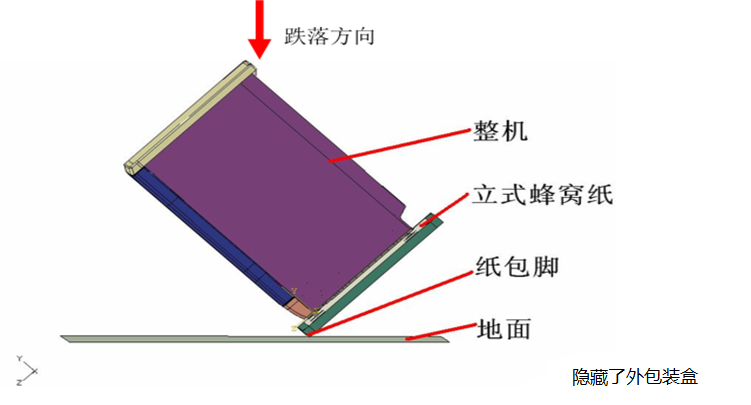

Brief Introduction to the Working Conditions of the Drop Simulation Analysis:

The simulation of drops includes the following common drop methods.

Working Condition 1: Bottom Drop Analysis

Working Condition 2: Front Drop Analysis,Working Condition 3: Edge Drop Analysis

Results of the Drop Simulation Analysis

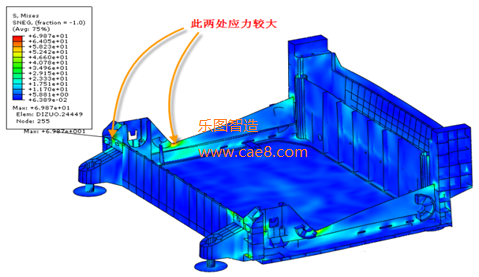

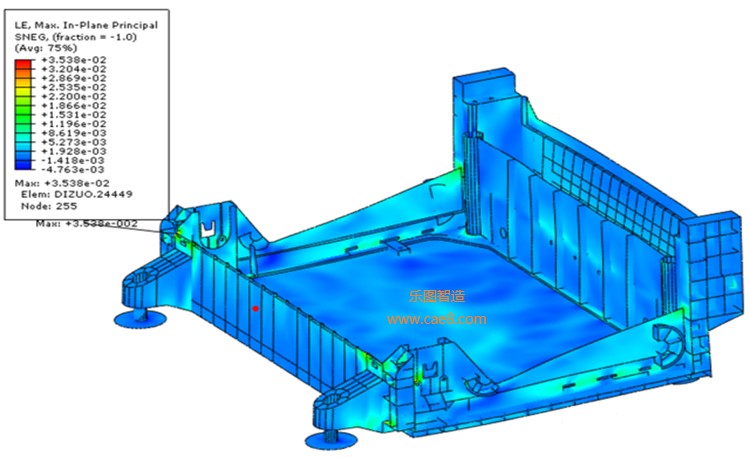

Working Condition 1: Bottom Drop Analysis

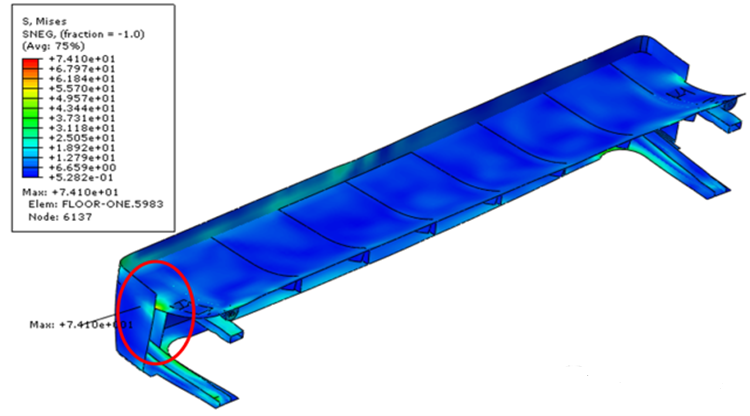

For the bottom drop, the base assembly bears the maximum stress. The maximum stress point is shown in the following stress and strain diagrams. It has exceeded the yield point of the material, but it will not break. However, the structural strength at this point needs to be strengthened.

The skirting board also needs to bear relatively large stress. The red-marked part may cause fractures, and the structural strength at this part needs to be strengthened.

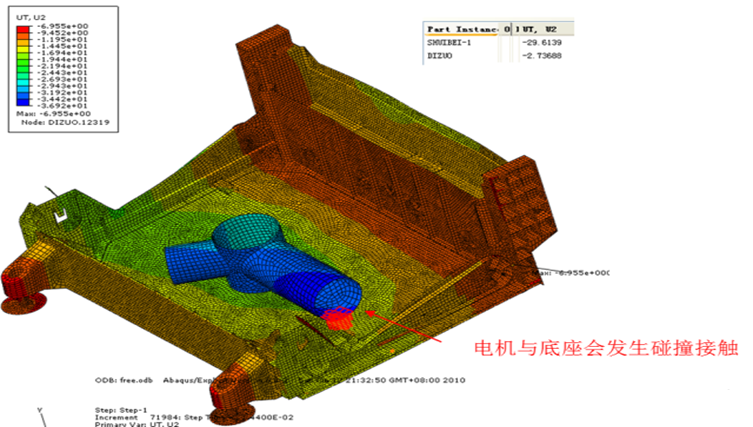

The following figure shows the vertical displacement of the end of the water cup motor and the part directly below it. The relative displacement is 27 mm, while the maximum distance measured in CAD is 11.6 mm. Therefore, there is a high possibility that the water cup motor and the base will collide.

Working Condition 2: Front Drop Analysis

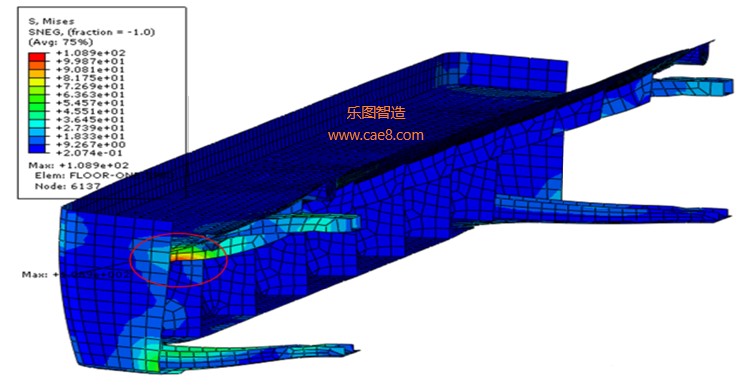

For the front drop, the maximum stress of the skirting board is 132 MPa. For the materials used, this stress value is relatively large. Since the materials used are brittle materials, the red area in the figure may break and needs to be optimized.

Working Condition 3: Edge Drop Analysis

For the edge drop, the stress of the part of the skirting board shown in the figure is too large (108.9 MPa) for the materials used, and there is a relatively high risk of fracture, so it needs to be optimized.

Conclusions of the Drop Analysis

Working Condition 1: Bottom Drop Analysis

Judging from the analysis results of the bottom drop, the front drop and the edge drop, the bottom drop is the worst. In view of this, it is recommended to increase the cushioning performance of the bottom packaging during the design process.

Working Condition 2: Front Drop Analysis

When the bottom drops, the stress of the stiffeners at the front independent adjusting feet on the base is relatively large. Although it will not break due to the large fracture elongation of the material, there is still a risk. When the bottom drops freely, the motor and the base collide. Both of these two points need to be avoided by strengthening the structural strength.

Working Condition 3: Edge Drop Analysis

In the simulations of the three drop methods, it can be seen that the skirting board is one of the weak areas most likely to break and needs to focus on studying its optimization scheme.

Declaration: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice