Motor magnetic field analysis Magnetic field intensity, magnetic induction intensity, magnetic field line distribution analysis

Business Content:

Electromagnetic Simulation, Magnetic Field Simulation Analysis, Magnetic Field Intensity Analysis, Magnetic Line of Force Analysis, High-frequency / Low-frequency Electromagnetic Simulation

Various motors

Various motors  Transformers

Transformers  Reactors

Reactors  Surge Arresters

Surge Arresters  Insulating Bushings

Insulating Bushings  Actuators

Actuators  Electromagnetic Sensors

Electromagnetic Sensors  Wireless Charging

Wireless Charging

Antennas/Antenna Arrays

Antennas/Antenna Arrays  Radar Scattering

Radar Scattering  Microwave Devices

Microwave Devices  Electromagnetic Compatibility/Electromagnetic Interference

Electromagnetic Compatibility/Electromagnetic Interference  Signal Integrity Analysis

Signal Integrity Analysis  Electromagnetic Propagation and Scattering

Electromagnetic Propagation and Scattering

Application Value of Electromagnetic Field Simulation:

1. The electromagnetic field simulation analysis of motors covers magnetic field intensity analysis, magnetic induction intensity analysis, and magnetic line of force analysis, providing a reference for structural and performance optimization.

2. It realizes the visualization of phenomena, which helps to efficiently produce products with better safety and connection functions.

3. Electromagnetic field simulation is mainly used in multi-domain simulations such as the Internet of Things, wearables, antenna design, radio systems/RF, circuit and motor analysis, transformers, and wireless charging. When analyzing EMC-related problems, it is necessary not only to analyze the signal waveforms of noise sources but also to analyze the conductors and space of conducted signals. In short, EMC analysis is not a simple analysis. However, electronic products can provide an integrated simulation environment, seamlessly connect the time-domain waveforms of system circuit simulation signals with electromagnetic field simulation, achieve field-circuit collaboration, and thus efficiently build virtual EMI and EMS tests.

Application Cases of Electromagnetic Field Simulation Analysis:

Case 1 - Permanent Magnet Synchronous Drive Motor of a Certain Pure Electric SUV

According to the principle of electric motors, the rotor is placed in a rotating magnetic field. Under the action of the rotating magnetic field, it obtains a rotating torque, so the rotor rotates. The power range of asynchronous motors ranges from several watts to tens of thousands of kilowatts, which can provide power for various mechanical equipment and household appliances. Electromagnetic simulation plays a very important role in the design of motors and electrical appliances. Electromagnetic simulation can predict parameters such as the efficiency of electromagnetic conversion, losses and heat generation of various components, and electromagnetic force/torque. It is the basis for further thermal simulation and structural simulation.

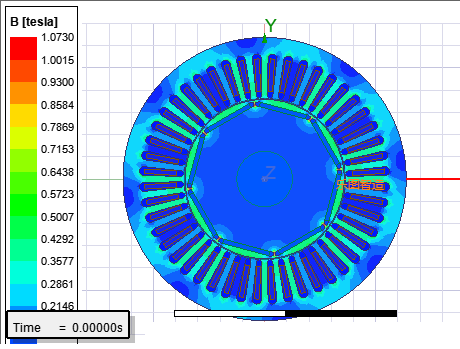

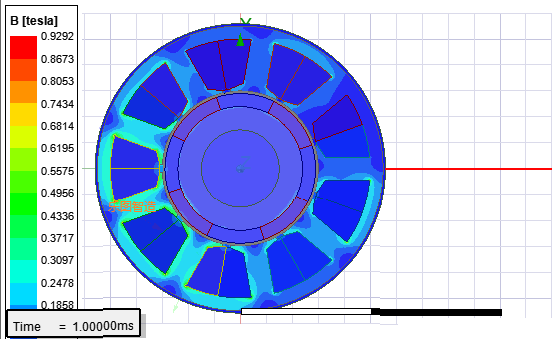

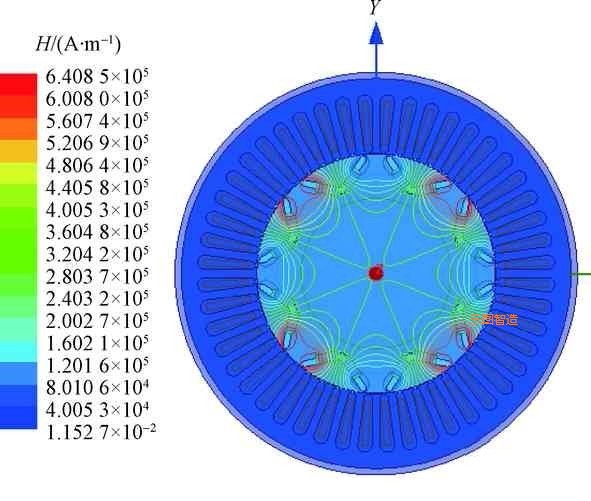

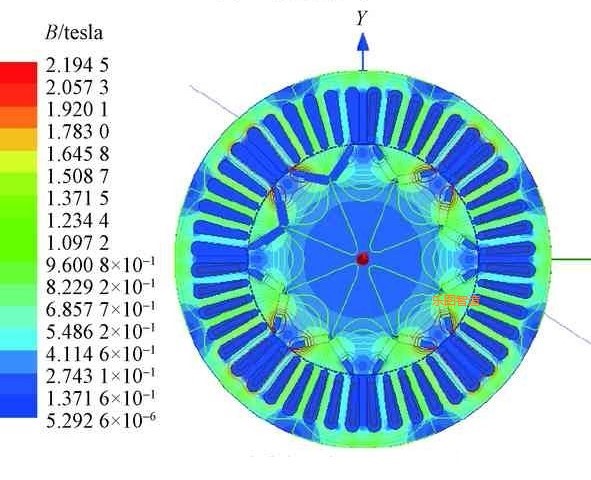

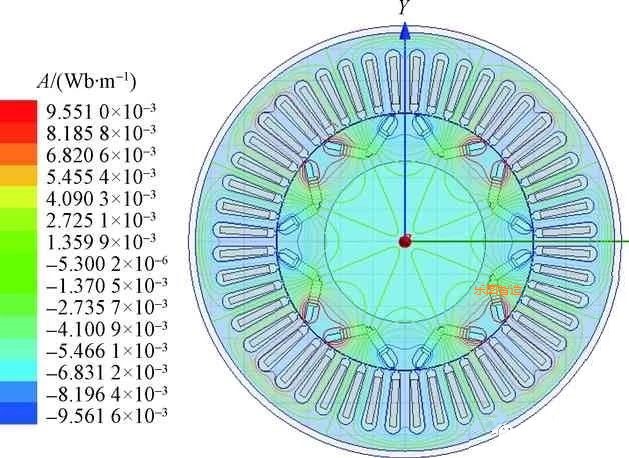

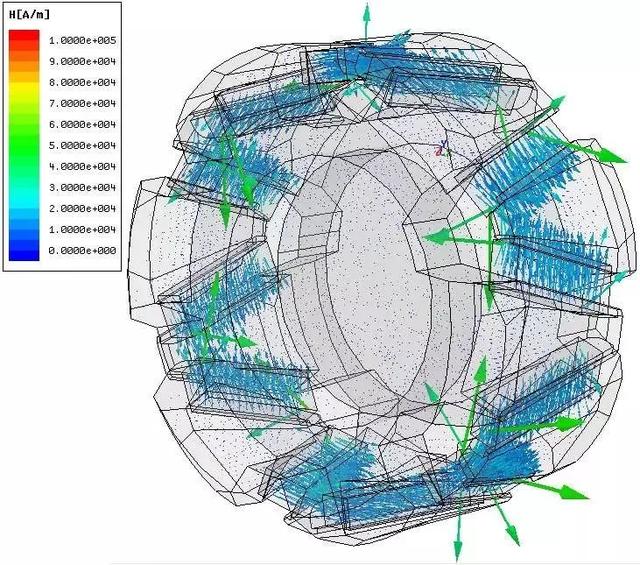

Preview of the Result Diagram of Magnetic Field Analysis of Permanent Magnet Motors

Comparison of Magnetic Flux Density Distributions of Two Design Schemes

Motors with 8 poles and 9 slots and motors with 8 poles and 48 slots are designed respectively. The following is the analysis and distribution of the magnetic lines of force of the motor magnetic field when the stator is energized.

Because the number of turns given during the design of the two motors is different, there are differences in the absolute values of the magnetic flux densities of the two. Judging from the magnetic flux density distribution of the two, for the fractional-slot motor with fewer slots (8 poles and 9 slots), since the windings are symmetrically distributed in space and are respectively distributed in a certain area of the motor, when a three-phase symmetrical current is applied, there will be a situation where the magnetic flux density is large in a certain spatial area of the motor, while the magnetic flux density in the remaining area is small, that is, the overall magnetic flux density distribution of the motor is uneven. For the integral-slot motor (8 poles and 48 slots), although the windings also show a symmetrical distribution in space, they are evenly distributed in the overall area of the motor, so the magnetic flux density distribution of the motor is relatively uniform.

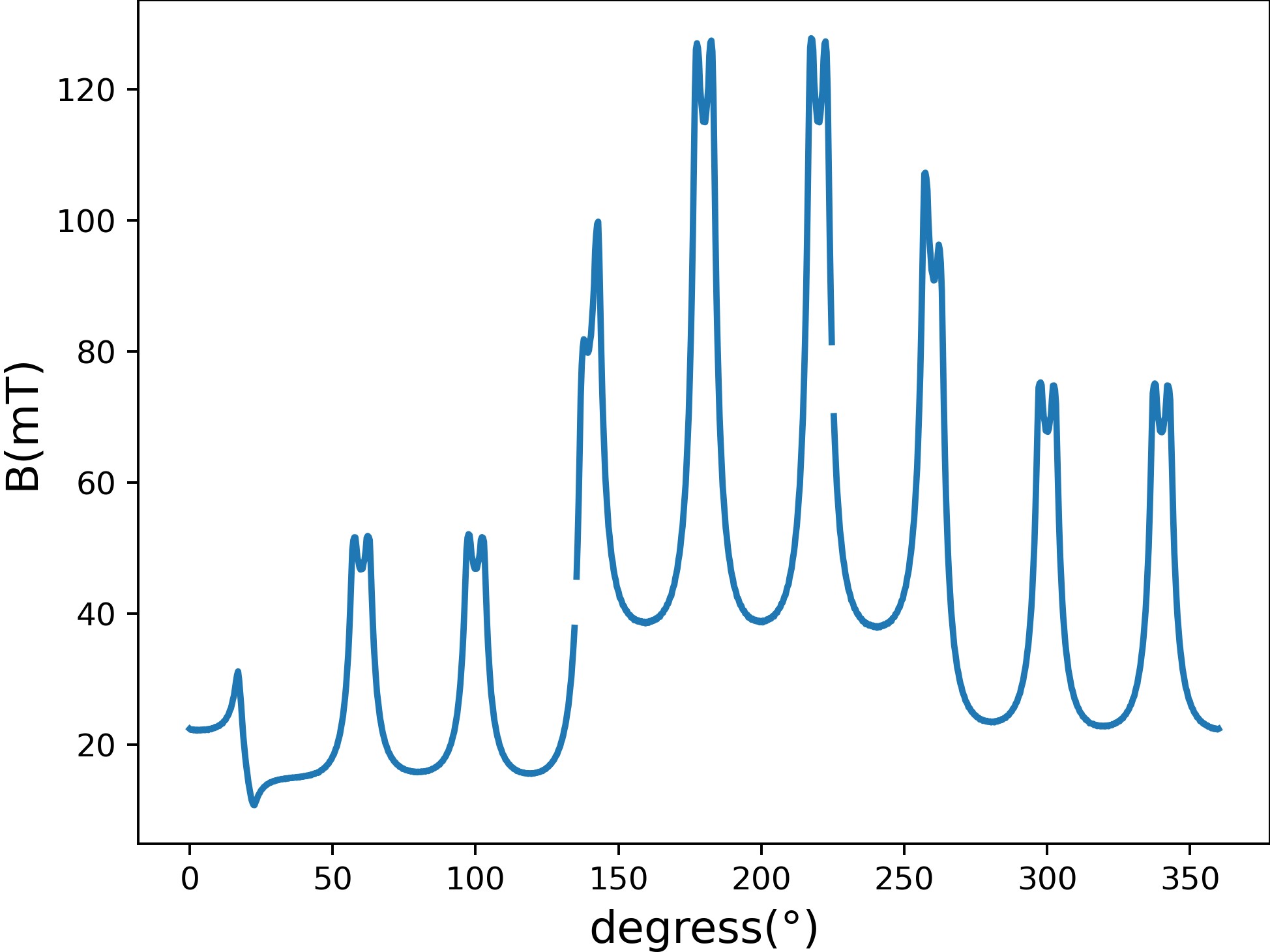

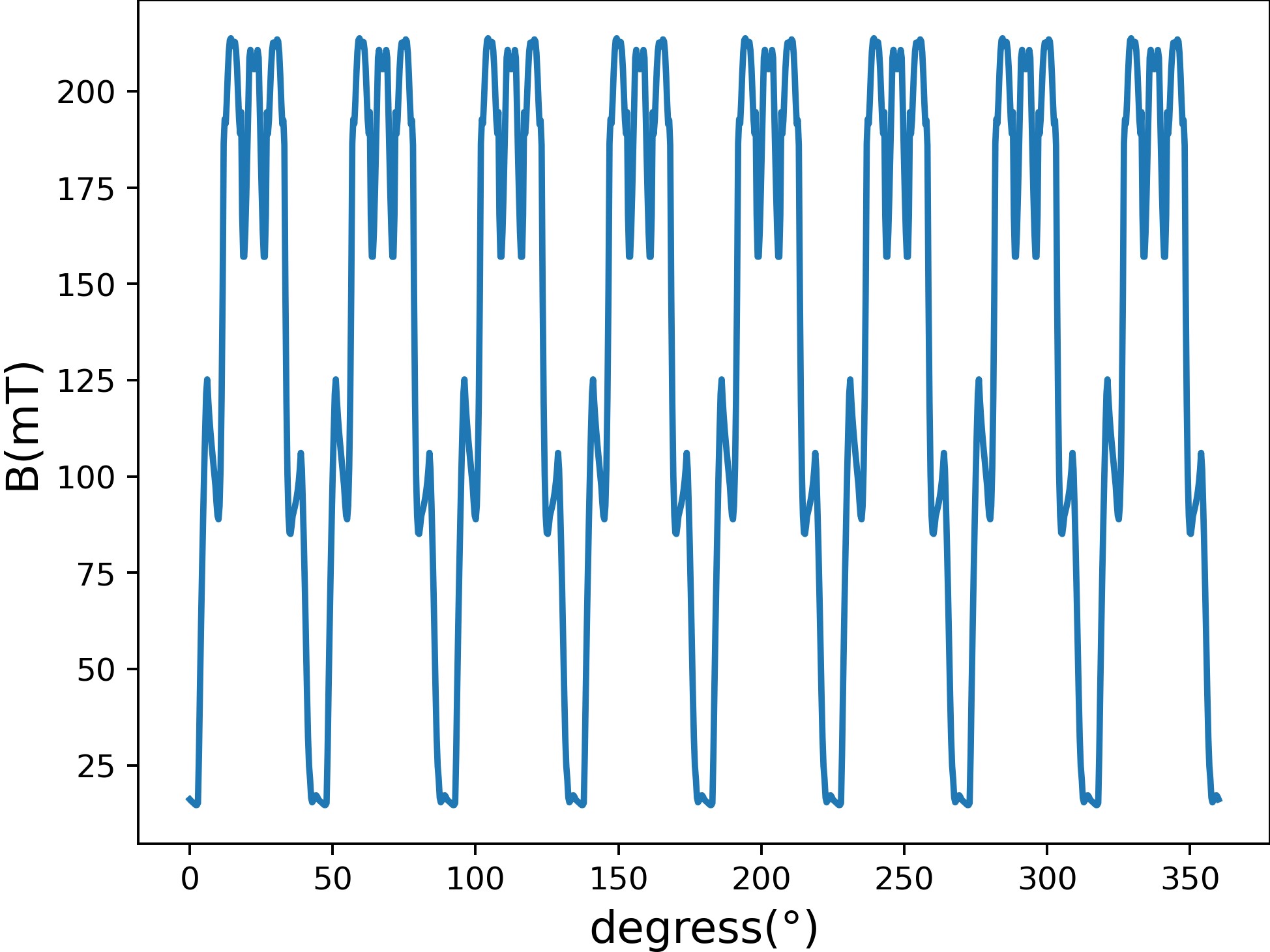

Magnetic Flux Density Waveform with Respect to Spatial Position (Mechanical Angle)

On the left is 8 poles and 9 slots, and on the right is 8 poles and 48 slots.

The result of the magnetic flux density waveform is consistent with the previous magnetic flux density distribution result. The magnetic flux density distribution of the integral 8-pole 48-slot motor has strong periodicity, while that of the 8-pole 9-slot motor is poorer. This result should not be judged only by looking at the stator. When we say that the sinusoidal property of the magnetic flux density of the 8-pole 48-slot motor is not good, it is not because the magnetic flux density waveform generated on the stator side has no periodicity, but because the magnetomotive force on the stator side is uneven in space and does not correspond to the rotor magnetic field. When it is superimposed with the magnetomotive force generated on the rotor side, the combined waveform is not good-looking. This superimposed magnetic field is what we really care about when analyzing vibration and noise problems.

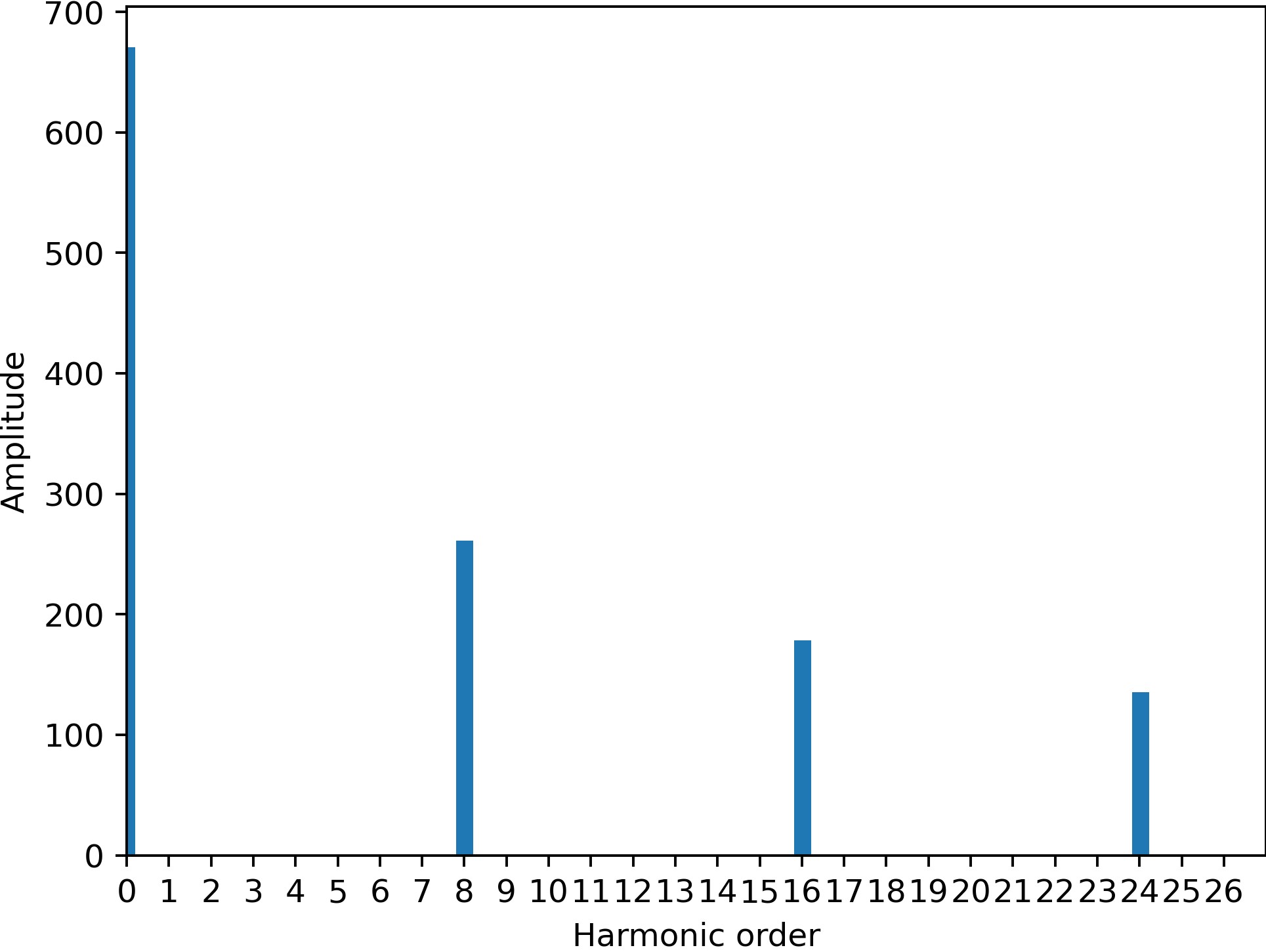

Fast Fourier Transform (FFT) was performed on the original data from the perspective of spatial angles, as shown in the following figures:

The difference in sinusoidal characteristics between the two can be seen from their FFT results. Due to the poor periodicity of the waveform, there are some low-order harmonics in the 8-pole 9-slot motor. The main harmonics are concentrated on multiples of 8 and 9. The existence of multiples of 9 is because the number of stator slots is 9 and the spatial distribution of the stator magnetic field and the rotor magnetic field is inconsistent. Therefore, harmonics that are multiples of 9 exist after decomposition. In contrast, the FFT result of the 8-pole 48-slot motor is much cleaner. The magnetic field distributions of the stator and rotor are consistent, and since the number of magnetic poles is 8, its harmonics are all multiples of 8.

Electromagnetic Field Analysis and Simulation of Water-cooled Permanent Magnet Synchronous Motors for Electric Vehicles

The results of magnetic field analysis include the magnetic field intensity of the motor, magnetic induction intensity, and the distribution of magnetic lines of force

Based on a certain pure electric SUV, the matching calculation of performance parameters and structural parameters of its permanent magnet synchronous drive motor was carried out, and the本体 design was completed. A circumferential spiral water-cooling structure was designed, the main heat sources of the motor were analyzed, the heat of the cooling system was calculated, and the electromagnetic characteristics of the motor were simulated by using Ansoft finite element software, covering the analysis of magnetic field intensity, magnetic induction intensity, and magnetic lines of force. Tests show that the designed motor can better meet the vehicle driving requirements. The selection and matching of drive motors need to be determined according to the dynamic parameters of automobiles. Currently, mainly based on the data of the maximum vehicle speed, the maximum gradeability of the vehicle, and the acceleration performance, the drive motor coordinated with the vehicle is selected and matched.

Case 2 - Hybrid Excitation Vehicle Generator

With the improvement of electrification and product intelligence, motors, transformers, and high and low voltage electrical appliances are increasingly applied in various equipment and daily life. Moreover, motors and electrical appliances are developing towards large capacity, small size, and intelligence. Today's motor and electrical design is facing more complex technical challenges, and only by making full use of modern engineering simulation technology can these challenges be met.

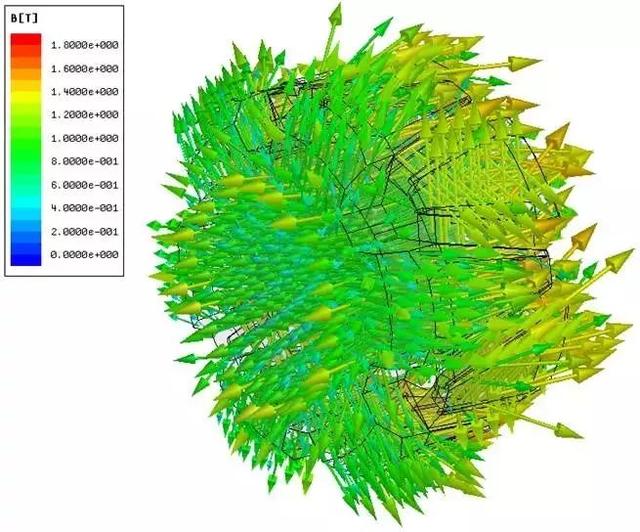

The following figure shows the magnetic flux density distribution and the rotor magnetic induction intensity vector.

The following figure shows the rotor magnetic field intensity vector (left) and the rotor magnetic field intensity vector (right).

Knowledge Expansion - Classification of Electromagnetic Simulation Analysis:

Steady-state magnetic field analysis: The excitation does not change with time, such as the magnetic field of permanent magnets, the magnetic field generated by steady current, etc.

Harmonic magnetic field analysis: The excitation changes according to the sine and cosine law, such as induction motors.

Transient magnetic field analysis: The excitation changes irregularly with time.

Declaration: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

View more cases:Die Casting Mold Flow Analysis Modal Analysis Electromagnetic Field Simulation Analysis Drop Analysis Fatigue Analysis CFD Analysis Casting Deformation Analysis Casting Simulation

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice