Sand casting magma analysis and simulation, casting shrinkage analysis and optimization

Business Content:

Authentic Flow3D, authentic magma casting simulation (recasting, sand casting, die casting, low pressure), casting defect optimization, casting program development, software sales.

Charge per set: Simulate customers with small needs.

Annual service: This method is recommended within 100 products a year.

Purchase software: More than 100 products a year recommended to buy software more cost-effective, detailed cost accounting comparison list, please consult 1586 2324 033

Application value of MAGMA analysis simulation:

1.MAGMA analysis and simulation can predict the possible location of shrinkage/shrinkage hole in advance, optimize the pouring and product design scheme, and improve the yield of castings. Authentic magma soft analyzes simulation results accurately and reliably, with the latest solution algorithms, the latest material library properties, and comprehensive results output.

2. Reduce cost and shorten development cycle. The rationality of the pouring system and the design of the product structure were verified by magma analysis and simulation. The era of numerical manufacturing technology guiding manufacturing is unstoppable.

3. Reduce the porosity, shrinkage, cold insulation, cracking and other sand casting molding defects, for you to improve the quality of castings, reduce manufacturing costs, numerical manufacturing technology magma simulation analysis to enhance your company's market competitiveness.

Casting shrinkage defect optimization case (forecast and optimized shrinkage) :

Part background (cast iron brake caliper) :

The casting is a ductile iron brake caliper, using sand casting process, developed and produced by Shanghai SSF Casting Co., LTD. Shanghai SSF Foundry Co., LTD. (SSF) is a subsidiary of Huayu Automotive Systems (Holdings) Co., LTD., located in Anting International Automobile City, Shanghai. The company manufactures GJL, GJS and CGI castings for the automotive industry with an annual output of 160,000 tons and a turnover of 1.9 billion euros. Production is mainly completed in 3 DISAMATIC production lines and 1 HWS production line. The company also has a dedicated test foundry and shell forming plant. SSF's customers include automotive Oems worldwide.

1. Original scheme - casting shrinkage defects:

Initially with the experience of the design of the casting program, the casting shrinkage is serious, a large number of shrinkage is found in the casting, and the scrap rate has reached more than 5.5%, because the production of this casting is very large, so this problem has become crucial. The customer decided to use an advanced scientific tool, magma simulation analysis, to identify the underlying cause of the defect and optimize the design solution to minimize shrinkage.

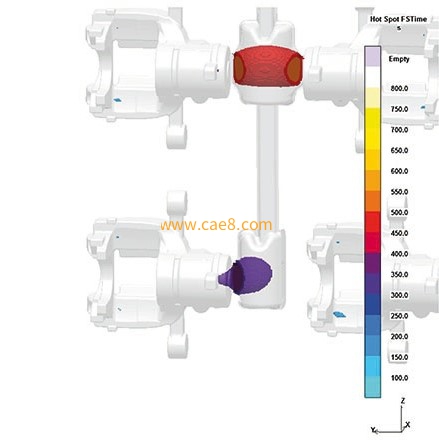

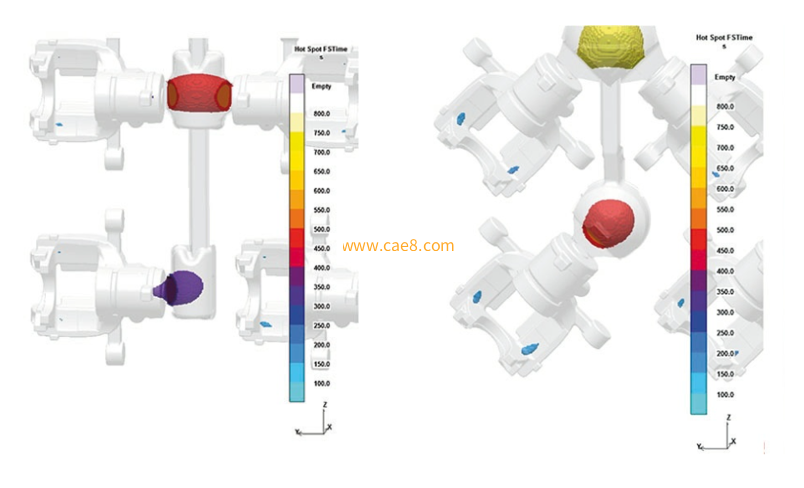

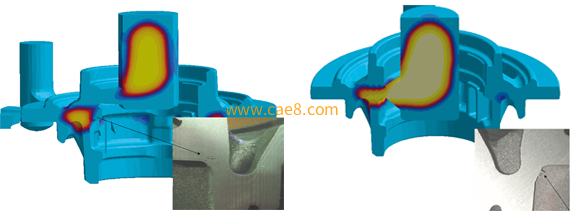

magma analyzed the simulation results (original casting scheme) :

The magma analysis and simulation results of the original mold show that there is a tendency of shrinkage in the neck area of the riser, which is consistent with the actual sample results.

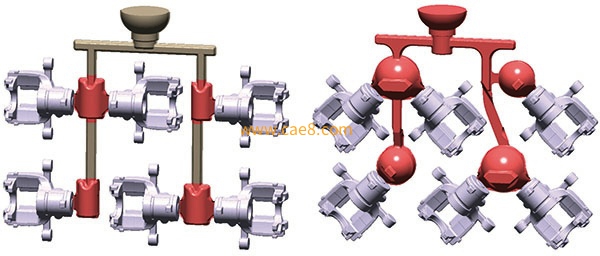

Optimization Scheme - Casting shrinkage improvement measures:

The gating system and flow channel design were optimized, the gating parameters and casting arrangement were optimized, which was more conducive to the material supplement during casting solidification.

Original casting layout (left) Optimized casting layout (right)

magma analyzed the simulation results (optimized casting scheme) :

Left side: original design plan Right side: optimized gate riser plan

Measures: Through the adjustment of gate parameters, the solidification time of gate and riser is synchronized, which effectively guarantees the metal solution feeding. The physical picture shows that the shrinkage problem can be solved.

3. Large-scale complex casting solution development a casting success:

Initially consider machining and material costs and other factors, subjectively do not want to place the riser at the arrow, and experience can not determine whether it will lead to shrinkage loose, this large complex casting sand shell is manufactured by 3D printing technology, and it will be a difficult thing to increase the riser after the test, and the cost of reprinting a higher cost. Therefore, the need to analyze and simulate with MAGMA during the development process will be a key link to achieve the goal of "forging success once".

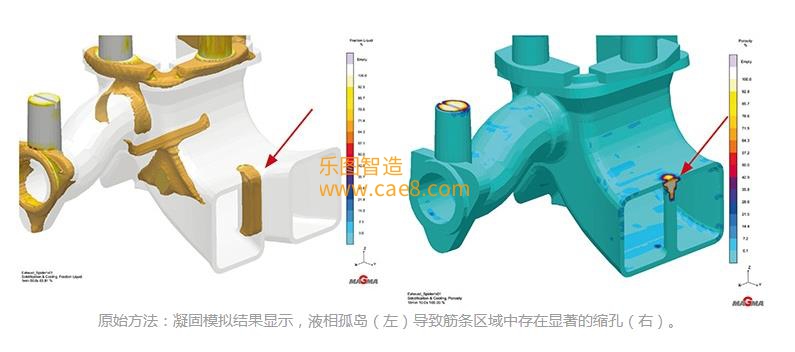

To solve this problem, engineers conducted magma analysis and simulation of the initial scheme. The solidification results of the lower left figure showed that there was a large area of isolated molten steel during solidification, and the shrinkage results of the lower right figure showed that the casting had a high risk of shrinkage holes.

Optimization scheme:

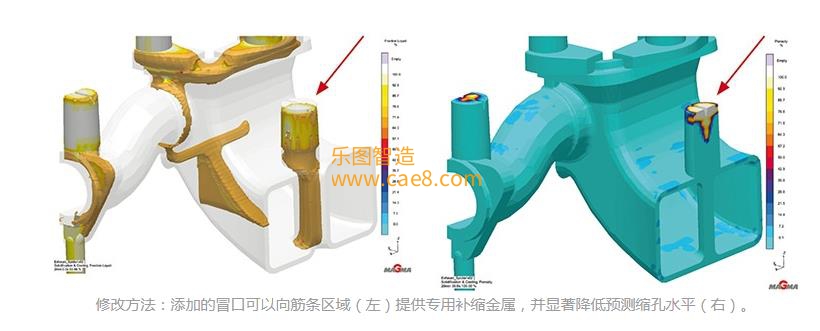

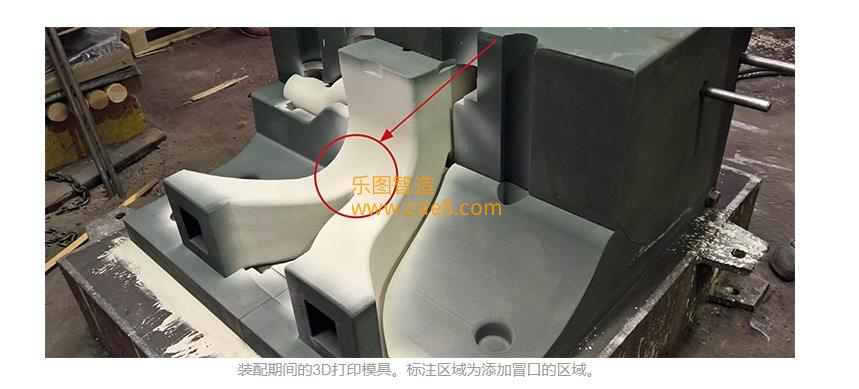

After a review of the design, it was determined that it was necessary to add a riser above the loose bar area, and a magma simulation was performed again to verify that the lower left image showed that the riser solidified later than the product and could be effectively filled, and the lower right image showed the shrinkage result, which significantly reduced the risk of shrinkage holes.

Based on the above magma software analysis and simulation results, with the support of reliable theoretical analysis data, we can rest assured that the sand shell can be printed. The following picture shows parts of 3D printed sand core and mold.

试样结果对比:

The manifold sample of the cast sample was machined to remove the riser and was inspected without shrinkage holes, exactly as MAGMASOFT's analytical simulation guessed. Because the output of large and complex castings is small, the process plan of using 3D printing sand mold is the most suitable, and the cost is also high. If you repeatedly redesign and 3D print new sand shell, it will cost a lot of money and time. Therefore, combining the needs of MAGMASOFT analysis and simulation in the development process will become the key link to achieve the goal of "forging success once".

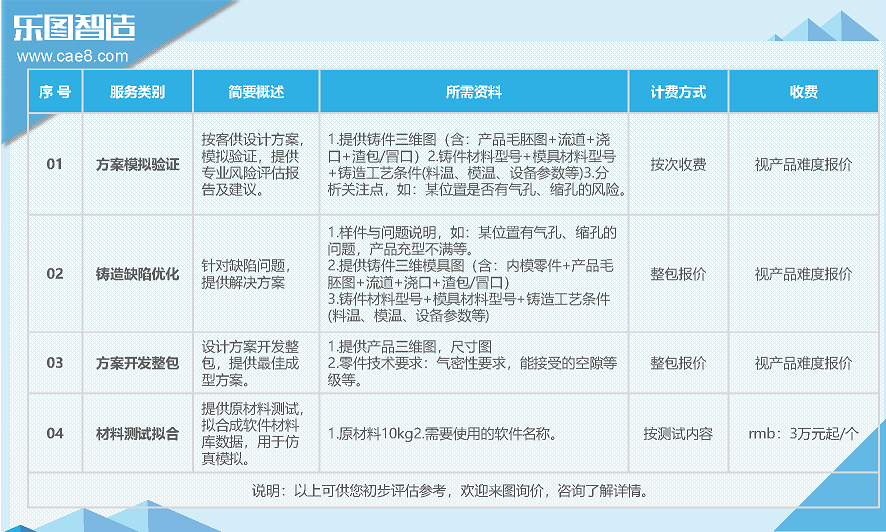

Charge method:

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice