Scan QR code and communicate with project manager

We look forward to your voice on wechat 24 hours

Business consulting/Technical consultation/ Technical consultation/ Technical consultation

Finite Element Simulation, What is Finite element analysis? What is the application value of finite element analysis?What is finite element analysis?Finite element analysis uses co

Finite Element Simulation, What is Finite element analysis? What is the application value of finite element analysis?

What is finite element analysis?

Finite element analysis uses complex mathematical equations, models, and simulations to understand how objects interact with physical forces. This helps engineers understand the persistence of an object and how to optimize it.

Finite element analysis is a structural analysis method that uses mathematical processes. FEA requires you to break up larger, more complex objects into more manageable parts. As you keep breaking down the structure, you get a better idea of how objects will respond to stressors. This method of decomposing structures for FEA is called the Finite element method (FEM).

What is the value of finite element analysis?

1, increase the design function, reduce the design cost;

2. Shorten the cycle of design and analysis;

3, increase the reliability of products and engineering;

4, the use of optimized design, reduce the consumption of materials or costs;

5. Identify potential problems in advance of product manufacturing or engineering construction;

6. Simulate various test schemes to reduce test time and cost.

What are the specific categories of finite element analysis?

Its applications cover almost all aspects of interest, such as force, shock, earthquake, temperature, noise, vibration, friction, durability, stiffness and weight.

1. Static/quasi-static analysis

Check the structural strength of all kinds of engineering structures, parts and assemblies

2. Vibration/modal analysis

Structure natural frequency extraction, transient response analysis, DDAM, steady state response analysis, random response analysis, complex eigenvalue analysis, etc

3. Highly nonlinear analysis

Geometric, material, boundary nonlinear analysis, using flexible and efficient automatic incremental step size to ensure convergence, adaptive mesh technology to solve large deformation problems

4. Contact analysis

Precise solution of large-scale contact problems, surface contact, automatic contact

The motion of the mechanism is analyzed, and the coupling analysis of structure and machinery is combined with the finite element function, and the contact and friction in the movement of the mechanism can be considered

6. Explosion and impact analysis

Explosion, airburst, high-speed impact

7. Drop and collision analysis

System level analysis and consideration of prestressing

8. Failure and fracture analysis of composite materials

Virtual crack closure technique, crack propagation simulation, progressive material failure

9. Thermal simulation analysis

Computers and data processing

Telecommunications equipment and network systems

Semiconductor devices, integrated circuits and components

Aerospace and defense systems

Cars and transportation systems

Consumer electronics

10. Electromagnetic simulation analysis

Wireless and wired communications, computers, satellites, radar, semiconductor and microwave integrated circuits,

Aerospace and other fields, from millimeter wave circuit, RF circuit package design verification,

To hybrid integrated circuits, PCB boards, passive board level devices, RFIC/MMIC designs,

Antenna design, microwave cavity, attenuator, microwave adapter, waveguide recorder design, etc.

Common process steps of finite element analysis:

Step 1: Model

When modeling an object, you should ignore complex geometric features and look at the basic structure of the object. Notice features that exist for structural reasons rather than aesthetic appeal. Learn why you want to remove one geometric aspect while keeping another.

Step 2: Material definition

As the name of the step implies, the material properties should be defined here. These depend on the type of analysis being performed. Experiment with different materials to check which one meets the desired requirements.

Step 3: Define the load

Your structure cannot exist in a vacuum. This step helps you determine which external forces are acting on the structure. How does it affect one component versus another?

Step 4: Boundary conditions

As we have done before in mathematical problems, setting the conditions under which the structure will exist is mainly to reduce the complexity of the problem. If we know the conditions in advance, it can help us save a lot of time when calculating.

Step 5: Mesh

The geometry of your structure is divided into smaller shapes, called finite elements. Meshing simply means connecting these finite element calculations to create a grid structure.

Note: The denser the grid structure, the more accurate the results will be. However, as you add nodes, complex calculations will increase.

Step 6: Solution

Simply put, it is to convert partial differential equations into algebraic equations. This will help to express the equation as a matrix. The singular matrix is then assembled into a global matrix, and the unknown variables are then solved.

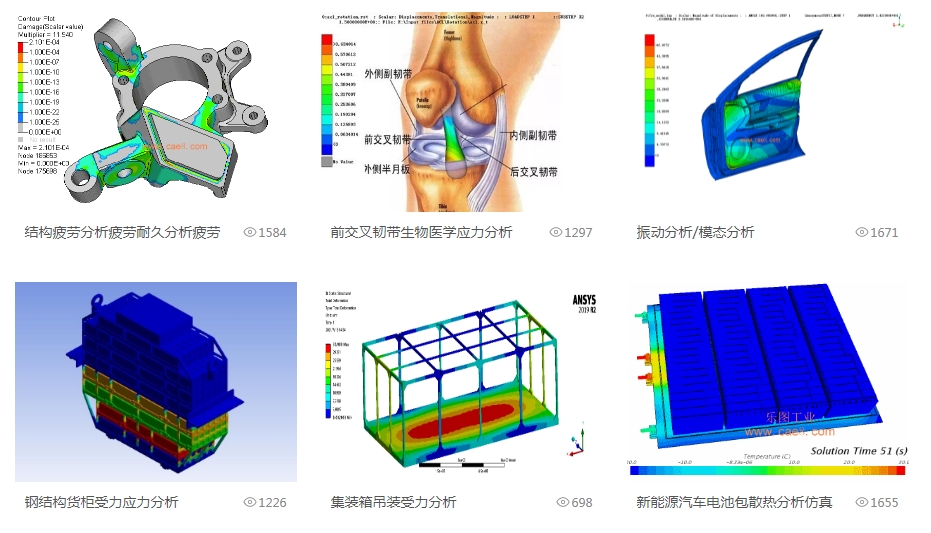

Finite element analysis case:

Modal Analysis CFD Analysis Electromagnetic Field Simulation Analysis IC chip Package analysis Rubber/silicone mold flow analysis

We look forward to your voice on wechat 24 hours

Business consulting/Technical consultation/ Technical consultation/ Technical consultation