Cfd simulation of planetary gear splash lubrication

Service Contents:

We have a professional CFD simulation team, which can provide you with professional CFD simulation technical services, agency services for finite element software, product performance optimization, mould forming optimization, prototype sample processing and other supporting services related to research and development.

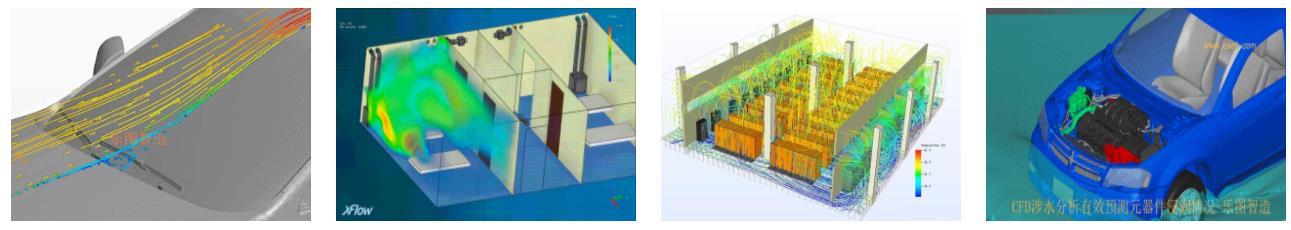

Application Value of CFD Simulation for Gear Splash Lubrication

Why does the gearbox need CFD simulation for gear splash lubrication?

Reason 1:

For traditional sample preparation and testing, the lubrication experiment with transparent shells has poor observability and cannot conduct quantitative analysis in a data-based manner. We can only confirm whether the lubrication is sufficient through experiments and blindly change the amount of oil for attempts.

Reason 2:

Lubrication simulation can greatly reduce the design risks. Through CFD simulation software, physical quantities such as the distribution, velocity, density and pressure of the lubricating oil at any time can be calculated, and the flow rate of the lubricating oil in the specified oil channels, oil loss due to splashing, etc. can be counted. Engineers can know the specific situation of the lubrication system through the results and optimize the design. They can even conduct simulations multiple times to accurately design the amount of oil at the design stage.

Reason 3:

It can shorten the project cycle and reduce the development funds. The design of a gearbox will surely undergo several modifications. Each time the model changes, a series of problems will arise, which will waste the project cycle. If the oil circuit needs to be modified due to problems with the lubrication system, considerable modification costs and uncontrollable design time will be faced. The finite element analysis and simulation of gearbox lubrication can complete the analysis and simulation of gear splash lubrication in a short time, which is much more efficient than traditional sample preparation and experimental testing.

What problems can the CFD simulation of gear splash lubrication evaluate?

1. Predict the oil splashing mode inside the gearbox for proper lubrication.

2. Predict the oil flow to bearings and other parts, optimize the oil volume design. Too much or too little lubricating oil will reduce the life and performance of planetary gears.

3. Predict the agitation losses at various speed ratios.

4. Optimize the design of vents in the gearbox.

5. It can simulate any number of gear sets.

The planetary gearbox is an important part of the transmission systems in many industries, including internal combustion engines, hybrid or electric vehicles. Oil splashing lubricates the gearbox, reduces friction and provides cooling for its optimal operation. For different situations of the movement of planetary gear sets, the model can be automatically set through finite element analysis of gear meshing. It predicts the oil splashing mode caused by gear rotation, agitation losses, oil drainage through vents, wet areas on gear surfaces and oil flow to bearings.

Lubricating oil is a necessary condition to ensure the good operation of the gearbox. However, too much lubricating oil will lead to a decrease in transmission efficiency, and too little lubricating oil will affect the life and performance of gears. During the operation of the transmission system, working conditions, the amount of lubricating oil and its viscosity-temperature characteristics are crucial to the performance of the gearbox. Since the experiment on gear splash lubrication is relatively complicated, the analysis and simulation research on gear splash lubrication can reduce the workload of costly experiments.

There are relatively complicated lubrication problems in planetary gear mechanisms. Different from ordinary gearboxes, too much or too little lubricating oil will reduce the life and performance of planetary gears. By using CFD simulation technology, detailed flow field information can be obtained in the early stage of research and development. Then, with low cost and accurate analysis and simulation results of gear splash lubrication, it can help to realize the forward design of gear transmission lubrication systems. It can be applied to crescent gear pumps, external gear pumps, screw pumps/compressors, helical gear pumps, Roots pumps, triple screw/gear pumps, planetary gears, internal gear pumps, etc.

Contact us for consultation, explore scientific manufacturing solutions and create higher added value together.

Letu Zhizao Technology is a professional CAE analysis company, providing scientific numerical information technology solutions, finite element analysis engineering services, software sales and manufacturing solution development for the manufacturing industry. Welcome to call us for inquiries. We are looking forward to your calls.

Disclaimer: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

View more cases: Battery Pack Heat Dissipation Analysis Die Casting Mold Flow Analysis Modal Analysis CFD Analysis Electromagnetic Field Simulation Analysis Drop Test Analysis CFD Simulation

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice