Moldex3D Software _ Leading brand of injection mold flow analysis software

As a first-level distributor in the Chinese region, we provide professional mold flow analysis technical services, material test fitting UDB, and sales of mold flow analysis software.

We will match software for you, offer pre-sales technical consultation, pre-sales quotations, software trials, after-sales technical training, and after-sales technical support. 1586 2324 033

Overview of Moldex3D Software:

Moldex3D is an injection molding simulation software and a leading brand of mold flow analysis software in the global plastic injection molding industry. With the most advanced real three-dimensional simulation analysis technology, it helps users in various industries around the world solve various plastic product design and manufacturing problems, shorten the product's time to market, and maximize product profits. Moldex3D completely provides different analysis tools required at various stages of the design chain. The eDesign series is a complete set of product and mold design tools, facilitating mold designers to quickly conduct verification before mold processing. Professional and Advanced are high-end plastic injection molding engineering analysis and optimization software, providing in-depth and complete analysis functions for various advanced manufacturing processes.

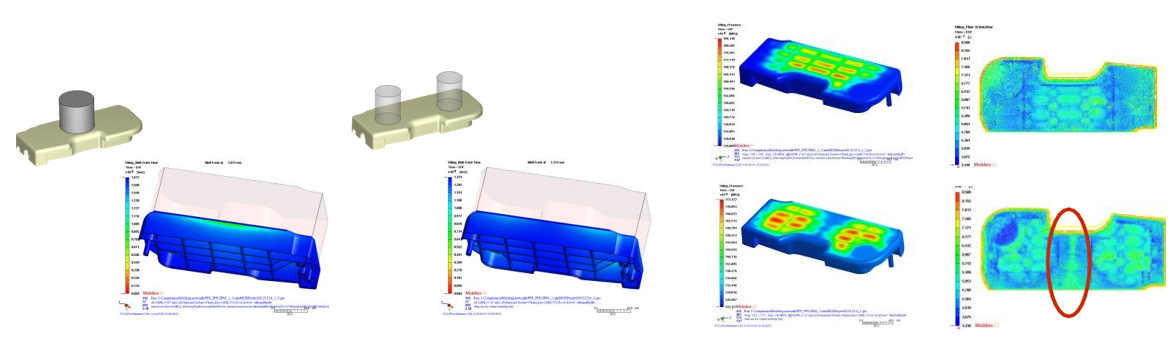

Core Functions of Moldex3D Software (Superior to Other Mold Flow Analysis Software)

Besides simulating and analyzing the injection process situations such as plastic filling, packing, molding cooling, fiber orientation, and plastic part warpage, Moldex3D can also be paired with various special modules to successfully simulate various high-end and special manufacturing processes, ensuring that users obtain comprehensive solutions.

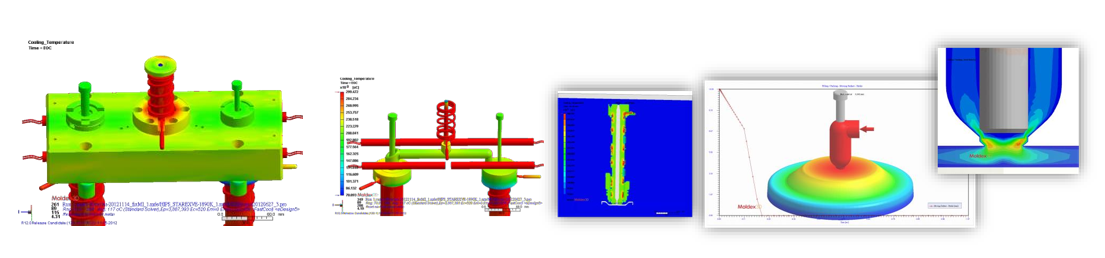

Hot Runner Temperature Analysis

It supports steady-state analysis and can make rapid pressure drop predictions for hot runner systems.

It can easily create meshes in air gap areas, visualize the temperature distribution within the hot runner system, and conduct more accurate heating rod/coil design verification.

It supports dynamic valve pin simulation, taking into account the position and operation of valve pins to observe the impact on the flow of molten glue.

It evaluates the thermal effects of the hot runner system (heat released to the mold base) and potential molding problems that may result.

It improves thermal uniformity, optimizes the heating cycle, and avoids the degradation of plastic materials.

Moldex3D software provides the best simulation tools for mold design engineers, enabling them to obtain key temperature distribution information in hot runner molding. Users can review the manufacturing process, discover potential problems, and then optimize the design to gain international competitiveness.

Injection Compression Molding Analysis

Grasp the process changes after compression and determine the optimal amount of filler.

Predict the optimal compression molding conditions to ensure that both large and precision parts have a perfect appearance.

Simulate fiber length orientation to avoid potential problems such as degradation or burrs and optimize product strength.

Integrate with LS-DYNA to provide a complete and accurate analysis of the compression molding process from the solid deformation stage to the liquid flow stage.

Moldex3D software provides a comprehensive injection compression molding simulation tool that can simulate the interaction of filling, compression, cooling, and warpage stages. During the mold compression stage, it allows the molten glue to pause or be injected simultaneously. Users can adjust different compression molding conditions to simulate real process parameters. Gas-assisted Injection Molding - The Moldex3D gas-assisted injection molding module provides simulation of gas entering the mold cavity from the gate position or other air inlets. The real three-dimensional technology allows users to view the flow of gas in the mold cavity at each stage, which is beneficial for optimizing mold design and molding conditions. It completely simulates complex manufacturing processes, accurately completes design verification and optimization, and successfully reduces development time and production costs.

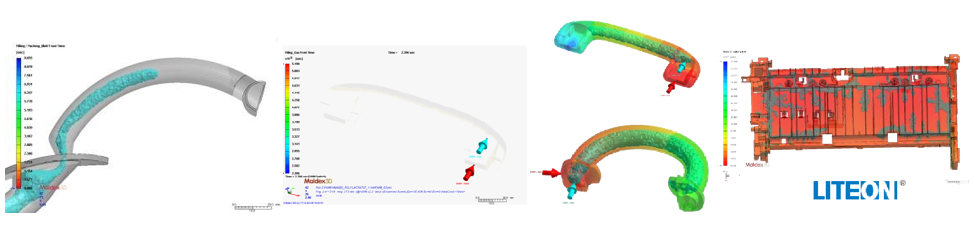

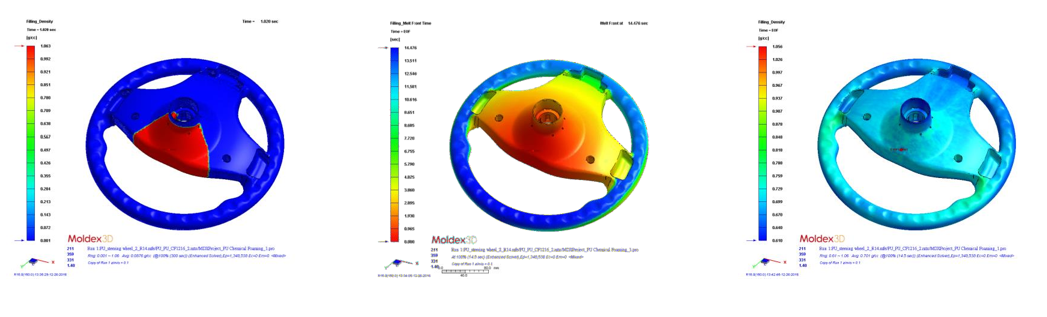

Water-assisted Injection Molding Analysis

Determine the injection time and injection volume of plastic and gas/fluid, and optimize the inlet positions of plastic and gas/fluid.

Optimize the thickness of the skin layer and the distribution ratio of the hollow core, predict adverse penetration, corner, and blow-through effects, and improve product defects.

The Moldex3D software's fluid-assisted injection molding module provides a complete set of tools to simulate the water-assisted injection molding process. The real three-dimensional technology allows users to view the flow behavior of molten glue and water at each stage, which is beneficial for optimizing mold design and molding conditions. It completely simulates complex manufacturing processes, accurately completes design verification and optimization, and successfully reduces development time and production costs.

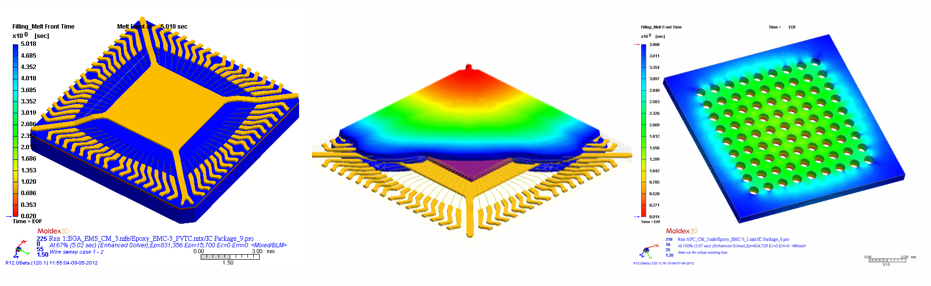

Microelectronic Component Plastic Packaging Analysis

Provide a complete series of chip packaging simulation solutions.

Clearly present the overall packaging process from filling, hardening to warpage, combining the characteristics of plastics and various components.

Fully consider the mutual influence between chip components and plastics.

The Moldex3D software's chip packaging module provides a complete 3D solution to assist engineers in analyzing the complex physical phenomena unique to the packaging process, thereby optimizing the design and process. Co-injection Molding - Moldex3D provides a powerful molding solution, allowing users to obtain key characteristics in the manufacturing process, such as materials and distribution, enabling enterprises to create more competitive advantages in process optimization and streamlined development costs.

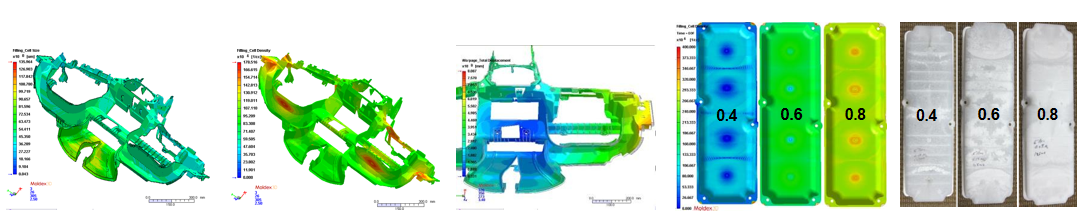

Microcellular Foaming Injection Molding Analysis

Visualize the flow behavior of gas-containing polymer melt in the mold cavity during the microcellular foaming molding process.

Consider the phenomena of bubble nucleation and growth, and simulate the distribution of bubble size and bubble density.

Evaluate surface quality and bubble effects, increase the weight reduction ratio, and improve the degree of shrinkage.

Support the core-pulling function to enhance foam simulation and better understand the changes and proportions of gas volume within bubbles.

Be able to output bubble size and bubble density data to Digimat for structural strength verification.

Support CBA material simulation in the initial gas concentration option for thermoplastic material analysis.

The microcellular foaming injection molding solution provided by Moldex3D software reveals the principle of the microfoaming process and provides an important reference basis for design, shortening the time from product design to market launch and effectively evaluating cost savings.

Investment Casting Wax Injection Molding Analysis

Moldex3D software can help precision casting manufacturers optimize the injection molding conditions of wax, reduce the occurrence probability of potential defects in the molding process, accurately predict the size of the wax pattern after shrinkage, and achieve optimization of the mold size.

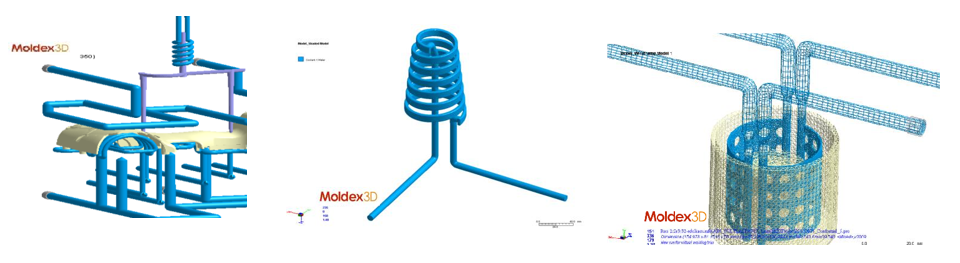

Special-shaped Waterway Analysis

Provide fast and convenient construction of complex geometric waterways.

Evaluate dead water areas through streamlines, pressure drop losses, and velocity/temperature results.

Verify the effect of the surface roughness of water pipes as a basis for modifying the current waterway design.

Reduce the overall flow rate difference.

Moldex3D software has advanced technology for simulating the flow in waterways. Product designers and mold developers can use the results such as viewing streamlines and velocity vectors to achieve design optimization.

PU Chemical Foaming Module Analysis

New simulation technology for the polyurethane (PU) chemical foaming process.

Predict the change in bubbles and density distribution under chemical effects.

Ensure that the product reaches the required bulk density ratio.

The advantages of polyurethane foamed products are that they can reduce the weight of the product itself, save material costs, increase the comfort of use, and have the effects of corrosion resistance, heat insulation, and sound absorption.

Moldex3D Mesh

Moldex3D mesh supports various mesh types, including 2D triangular and quadrilateral meshes, 3D tetrahedral, prismatic, hexahedral, voxel (brick), and pyramidal meshes. Moldex3D mesh provides multiple mainstream meshing methods: pure triangular surface, tetrahedral-based surface mesh; pure tetrahedral mesh, boundary layer mesh, pure voxel mesh, hybrid solid mesh, and mid-surface simplified mesh. Customers can choose from them to meet their own special simulation needs to build mesh models.

Top Ten Reasons for Choosing Moldex3D

1. Seamless integration with mainstream CAD platforms

2. Parametric gate/runner/waterway wizards

3. Real 3D runners can clearly observe the phenomenon of flow imbalance.

4. Real injection molding machines and mold considerations (real machine interface, screw fiber breakage, advanced cooling analysis)

5. A high-precision fiber orientation model that has been fully verified.

6. Excellent parallel computing, with a four-core system that can accelerate by 3 times; also provides cluster parallel computing.

7. Outstanding R&D capabilities and support, with the headquarters in Asia and Chinese communication available.

8. Cost-effective paid support from professional material laboratories.

9. Focus on plastic injection CAE, with a faster development speed than Autodesk Moldflow.

10. Excellent customer service.

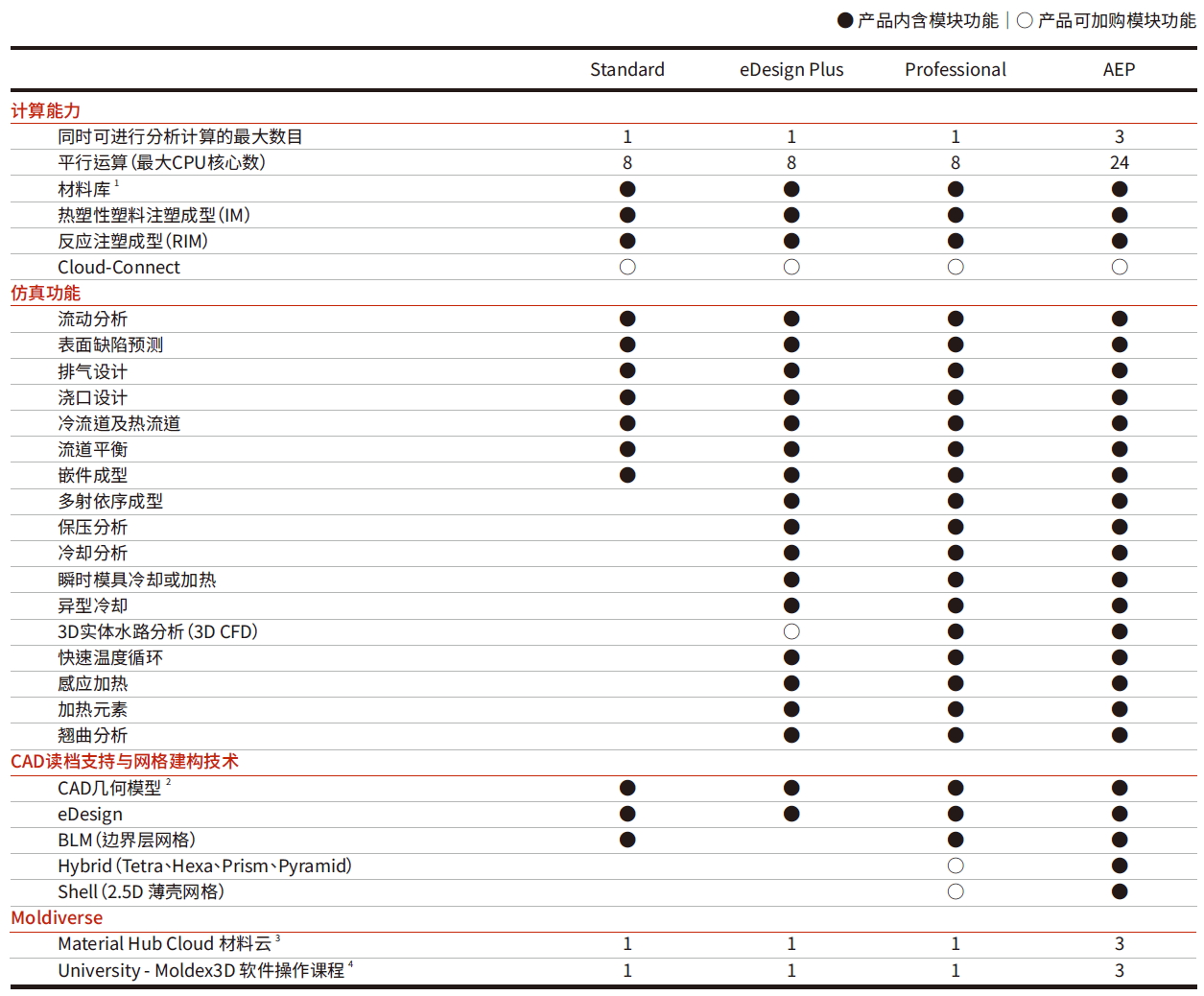

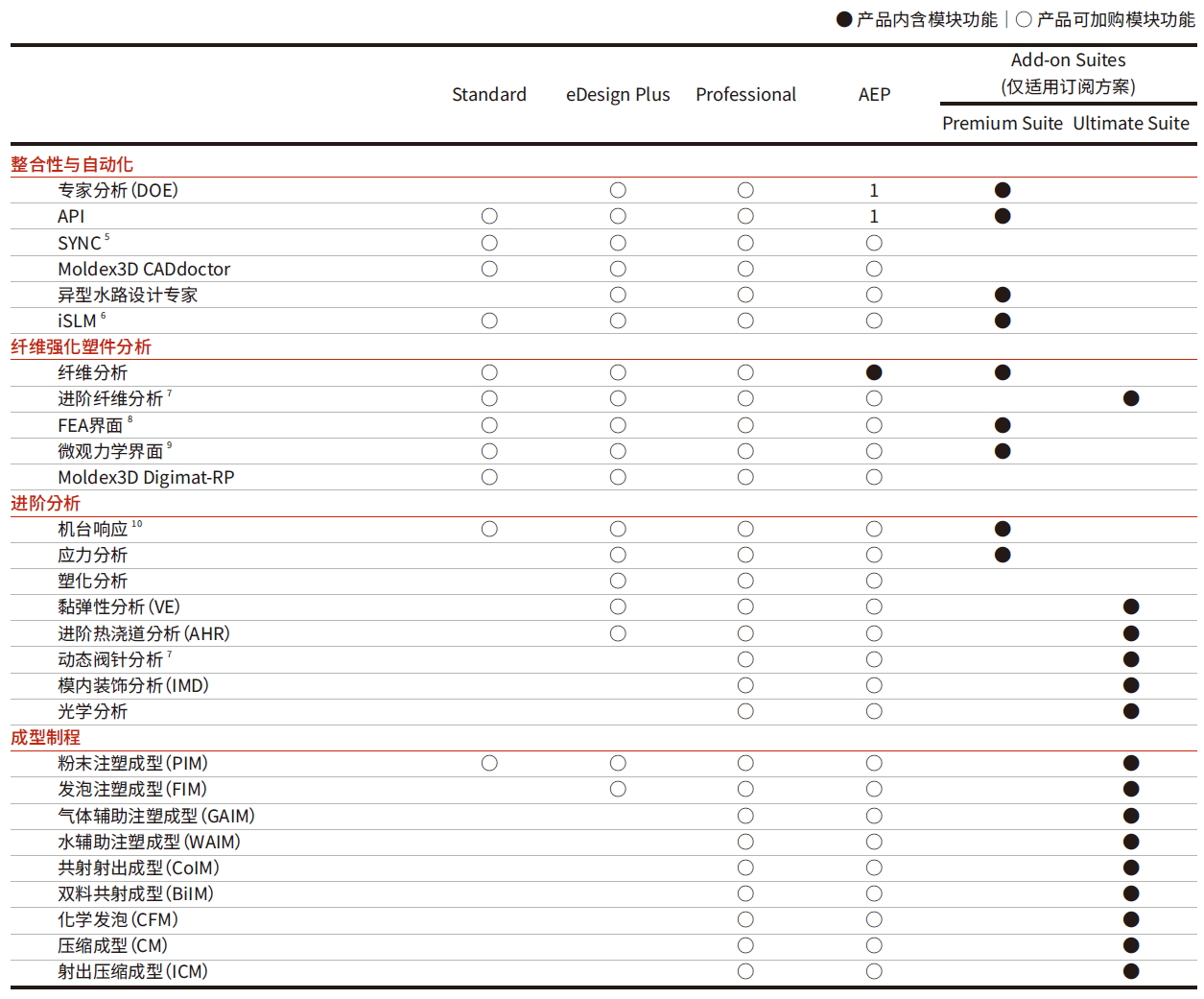

Product and Module List

Contact us for consultation and get detailed software introductions and quotations.

We will match software for you, offer pre-sales technical consultation, pre-sales quotations, software trials, after-sales technical training, and after-sales technical support. 24-hour business hotline: 1586 2324 033

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice