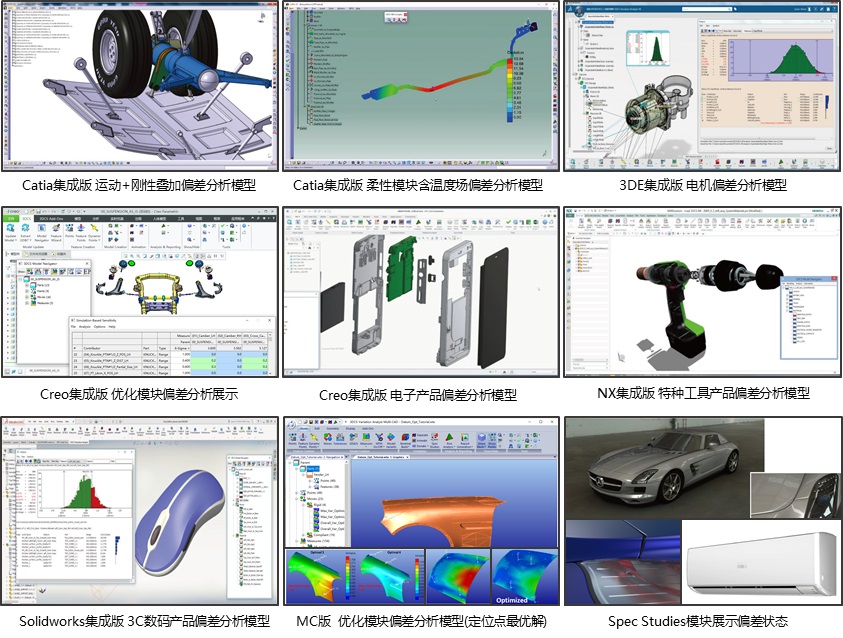

3DCS software, dimension chain calculation and tolerance analysis software

Sales of Genuine 3DCS Software, Dimension Chain Tolerance Analysis Services

Apply for free software trials, dimension chain calculation and tolerance analysis services, pre-sales inquiries, and technical support. 199 4191 2022

Welcome to call for detailed software introductions and quotations.

Overview of 3DCS Software:

3DCS is a software for dimension chain calculation and tolerance analysis, which can provide digital visual size inspection interaction for the actual manufacturing process.

It is a widely used dimensional tolerance simulation software.

The 3DCS deviation analysis software is used by the world's leading OEM manufacturers to reduce their quality costs. By controlling deviations and optimizing designs while taking into account inherent process and part tolerances, it helps engineers reduce the costs of nonconforming products, scrapping, rework, and warranties.

It is a leading software solution for dimension chain calculation and tolerance analysis.

The 3DCS tolerance analysis software based on NX is an integrated solution paired with NX. This enables users to directly activate the 3DCS workbench from within NX and use many of NX's inherent functions to support deviation modeling.

Simulate the deviation of part and process dimension chains.

The software uses a three-dimensional simulation method to emphasize the sources of deviations and potential assembly problems of products. By accurately simulating the assembly process, users can vividly simulate products in a virtual environment and test and verify design goals by creating digital prototypes.

Digital visual interaction enables new insights into the design.

Through simulating products in a digital environment, the dimension chain calculation and tolerance analysis software allows engineers to consider deviations in key areas, reducing rework, nonconforming products, and product scrapping during final assembly. In addition, some unimportant specifications can be relaxed to increase tolerances, allowing the use of cheaper manufacturing processes, thereby reducing costs without affecting overall quality. The 3DCS software has the function of automatically generating reports, which can quickly and effectively communicate analysis results and facilitate collaboration with colleagues.

The 3DCS tolerance analysis software is a leading technological product that provides solutions for dimensional engineering. In the actual manufacturing and process production of products, dimensional engineering is a crucial component in Product Lifecycle Management (PLM).

The 3DCS software emphasizes the simulation of dimensional deviations in digital assembly and the data management of actual production data, ultimately forming a digital twin architecture system for closed-loop quality improvement. Dimensional engineering requires that actual components and assembly processes match predetermined relevant dimensional requirements, and the 3DCS tolerance analysis software can more accurately determine and communicate assembly and measurement contents, simplify product verification processes, and reduce production and manufacturing costs.

The 3DCS dimension chain calculation and tolerance analysis software has expanded modules such as 3DCS Mechanical, 3DCS FEA CM, 3DCS AAO, and 3DCS Visualization Export on the basis of the original standard tolerance analysis module, providing excellent solution capabilities for product design and manufacturing, dimension and quality control, etc., fully supporting customers to achieve dimensional quality goals, enabling new products to be quickly launched into the market and enhancing the market competitiveness of products.

Introduction to the Functions of 3DCS Tolerance Analysis Software:

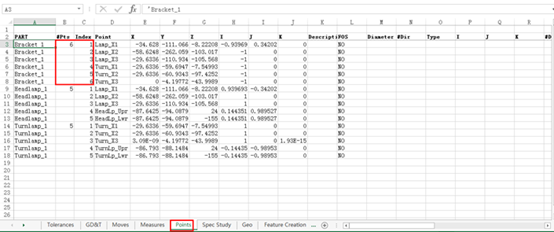

3DCS Excel Create Function

It is used to export model information such as Point, Move, Tolerance, and Measurement in the 3DCS model to Excel. After batch renaming, adding, and deleting models in Excel, the models can be imported back into 3DCS to achieve batch and rapid editing of existing 3DCS models. The introduction is as follows:

Click "Write to Excel" on the 3DCS interface to export the 3DCS Data of the model to Excel, and an Excel document will pop up automatically.

Modify the existing points in the model in the "Points" list. You can modify the Name, coordinates, direction, tolerance attributes, etc. If you need to create a new point, you need to modify "#Pts", "Index", copy and paste a new row, and add the information of the new point in the new row according to the original data format.

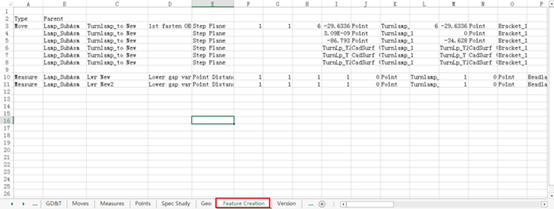

Modify the existing MTM in the "Tolerances", "Moves", and "Measures" lists. To create a new MTM, you need to call the Excel Create license, copy the existing MTM to the "Feature Creation" list in the "Feature Creation" list, and modify it according to the existing format, as shown in the above figure. After modification, click "save as" to save it as a.xls or.xlsx format document, and then close the document.

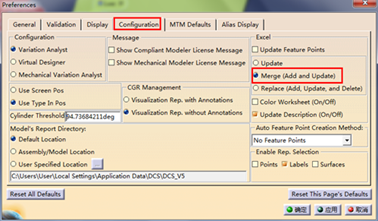

In the "Preference>Configuration" column, check "Merge (Add and update)", click "OK" to exit; click "Read from Excel", select the document saved in the previous step, and click "update model" to complete data reading and refreshing.

Visualization Export Function

The 3DCS appearance quality perception module, combined with the 3DCS deviation analysis function, shows the impact of tolerances and deviations on the appearance of the final product through Gap and Flush. It allows engineers to evaluate and analyze the appearance quality effect of the product from the user's perspective. 3DCS can be seamlessly combined with 3DE Live Rendering and VR devices to achieve quality perception analysis based on virtual reality.

1. Export the virtual deviation state created by Spec Study to third-party rendering software to obtain a realistic visual perception effect.

2. Output fbx files and use high-end visualization tools (Deltagen, VRED, Showcase) to create a seamless workflow;

3. Convert your model into visual images to show the appearance of the actual product under given design specifications.

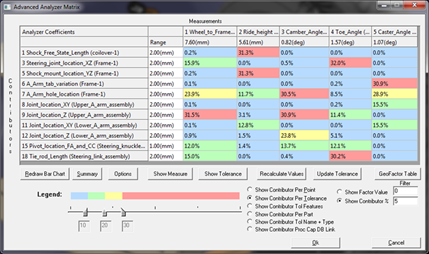

3DCS Advanced Analyzer and Optimizer Function:

- Analyzers can quickly process large models and obtain a global view of deviations.

- Optimizers are used to determine the best tolerances and designs and automatically assign optimal tolerances.

- LSA positioning sensitivity analyzers test positioning schemes and determine the best options.

- SBS performs simulation calculations on the tolerance sensitivity and correlation of nonlinear models based on the Monte Carlo algorithm.

- Sequence Optimizer determines the best connection/clamping sequence from a set of candidate connection/clamping schemes. Users can optimize the clamping order or connection order.

Joint Simulation Function of 3DCS and Finite Element Software:

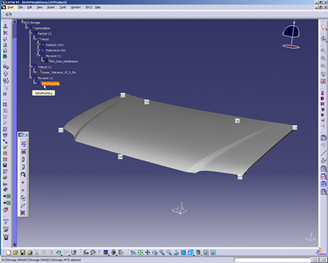

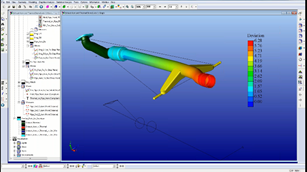

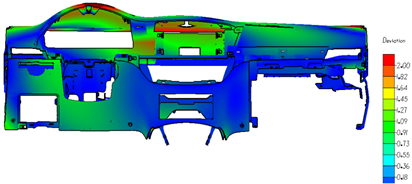

The 3DCS FEA Compliant Modeler flexible module uses the finite element simulation analysis method to accurately simulate the deviation changes in the manufacturing and assembly processes of parts. It is used to analyze the impact of deformation deviations on product quality goals when parts are subjected to loads such as over-constraints, clamping, gravity, temperature fields, and torque under different tolerance states. It is often used for flexible parts that are prone to deformation, such as automobile side panels, front and rear bumpers, hoods, fenders, interiors, aircraft fuselage skins, wings, tail fins, and electronic product boards.

Highlights of the Functions of 3DCS Tolerance Analysis Software:

1. Determine the deformation effect of the assembly and manufacturing process on flexible materials (aluminum, sheet metal, plastic);

2. Apply forces to parts to determine the impact on the overall deviation;

3. Optimize processes, such as welding sequence, riveting, bolt and tool installation;

4. Incorporate finite element analysis into tolerance analysis. It belongs to the joint simulation of finite element analysis software and dimension chain calculation and tolerance analysis software.

FEA_CM simulates the over-positioning deformation of the hood.

Application of FEA_CM in the temperature field analysis of the exhaust pipe.

Application of FEA_CM in the IP&CCB assembly analysis.

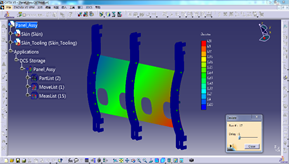

Application of FEA_CM in the positioning of aircraft skin tooling.

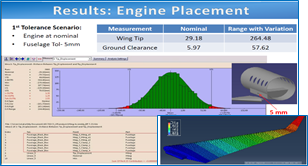

Application of FEA_CM dimensional tolerance simulation analysis software in the analysis of the wing ground clearance.

Today's design and manufacturing industries are changing rapidly. To reduce costs and bring products to the market before competitors, it is necessary to ensure the correctness of the engineering design scheme at the early stage of design. In the entire engineering definition, the ability to quickly and accurately analyze dimensional deviation problems is a key requirement to meet this challenge. Based on this engineering background, the 3DCS tolerance analysis software integrates advanced tolerance analysis and visualization technologies into multiple mainstream three-dimensional CAD environments such as CATIA V5. In this way, before processing and production, engineers can visually define, test, and modify product dimensions and processes in a three-dimensional digital environment.

Contact us for consultation and get detailed software introductions and quotations.

3DCS Software, 3DCS tolerance analysis services, 3DCS dimension chain calculation and tolerance analysis software sales, finite element simulation matching software, pre-sales technical consultation, pre-sales quotations, software trials, after-sales technical training, after-sales technical support. 24-hour business hotline: 199 4191 2022

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice