flexsim software Production line logistics simulation software

Production line/logistics simulation service, Purchase flexsim software, pre-sale inquiry, application for software trial, technical support. 199 4191 2022

FlexSim software Introduction:

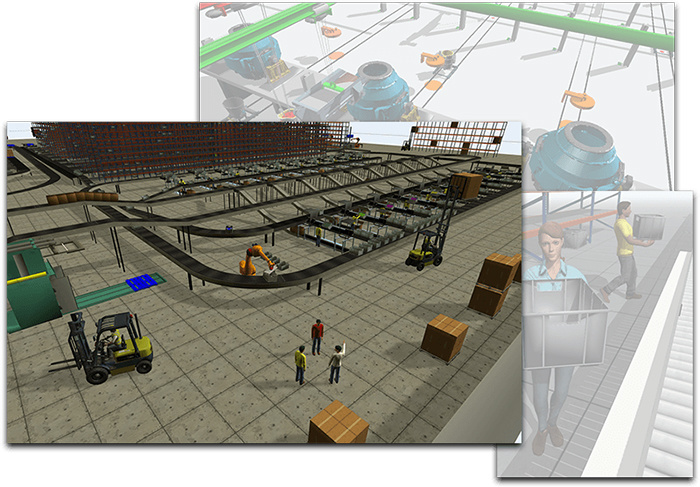

FlexSim software is a powerful discrete event simulation software developed by FlexSim. <span style="text-wrap: wrap;" The FlexSim software allows you to visually demonstrate, test, and analyze any type of process, manufacturing, material handling, logistics, warehouse, or management change in the fastest way possible, without the cost, risk, and time required to try and error in the real world. The simulated system can be analyzed, optimized and improved through trial and error.

Industry Application:

FlexSim has been successfully used in many industries, including manufacturing and logistics, including 3C, automotive, battery, semiconductor, furniture and home appliances, steel, heavy machinery, airports. Tobacco, chemical, wood, transportation, port, medical and other industries, covering production, packaging, warehousing, transportation, distribution, information processing park and other supply chain solutions, strong to build a discrete system simulation brand.

Used in automated manufacturing :

Flexsim can simulate any process from unit operation, assembly line, shop floor to the entire plant, taking into account various variables (such as order/production schedule, quantity of resources, inventory, scrap, MTBF MTTR, cost, etc.). Present the current state of the system and identify waste, validate and optimize resources in the form of visual and statistical reports.

Virtual modeling of computers based on real production systems. Warehousing, assembly, transportation, and production can all be modeled to make decisions that maintain or improve efficiency at the lowest possible cost.

Applied to logistics warehousing:

FlexSim has a wealth of storage system modeling elements (shelves, conveyor belts, robots, trucks, AGVs, etc.) to improve operational efficiency by optimizing resource allocation, improving storage utilization, optimizing storage efficiency, reducing travel distances, etc., thereby reducing logistics costs and helping you better understand and improve your real storage system.

Warehouse simulation

Warehouse simulation uses computer models to better understand and improve real warehouse conditions systems. Simulation is a proven technique that enables organizations to analyze and experiment with base warehouse processes in a hypothetical environment, thereby reducing the time and cost involved in physical testing. Storage, head stations, conveyor belts, AGVs, and even people can be quickly introduced and adjusted in a simulation model. Let businesses determine how best to make the most of their resources and maximize efficiency.

Full 3D simulation, jump out of the outdated environment and into our custom realistic 3D environment!

Flexsim brings a better visual experience to simulation modeling, providing rich,3D objects to make your models look more realistic,3D simulation modeling brings the system to life, and helps promote communication between people at all levels.

For medical systems :

For modeling and optimization of hospitals and healthcare systems. Flexsimn HC Medical Simulation software allows you to analyze every aspect of a patient's medical process and assess how potential changes will affect your healthcare system, all in a patient-centered virtual environment where the solution you find will be accurate and will help your healthcare organization be as efficient as possible.

Changing real-world medical processes is risky, costly, and time-consuming - simulation with the FexSim HC first to make sure the risks and costs are manageable!

Patient flow simulation

In a real life healthcare environment, the patient drives all activities, and the patient Flow Generator makes this behavior possible in the fexsimnHC model, where you can drag out and arrange flowcharts of activities and processes based on the patient's vision, diagnosis, and any other user-defined characteristics, which is the most complex part of creating the model. We spent countless hours making it as intuitive and simple as possible.

Patients do not move like parts in a manufacturing plant, they are not pushed from one process to another, instead, patient proces fow Buider simulates human power

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice