Simulation of IC chip package mode flow analysis

Service Contents:

Gold and silver consultants, mold flow analysis of IC chip packaging, analysis of gold wire shift amount, optimization of molding defects, UDB material test fitting, and sales of Moldflow/Moldex3D software.

Application Value:

Many problems often encountered in the molding of IC chip packaging, such as substrate warpage, gold wire deformation analysis, chip shift, trapped gas during filling, and incomplete filling, can be simulated through Moldflow or Moldex3D mold flow analysis software for the simulation of IC chip packaging mold flow analysis.

The predictable problems are as follows:

1. Truly predict whether the gold wire shift amount is within the tolerance.

2. Predict the impact of gold wire density on the flow of molten glue.

3. Predict the maximum shift index value of each gold wire in the model.

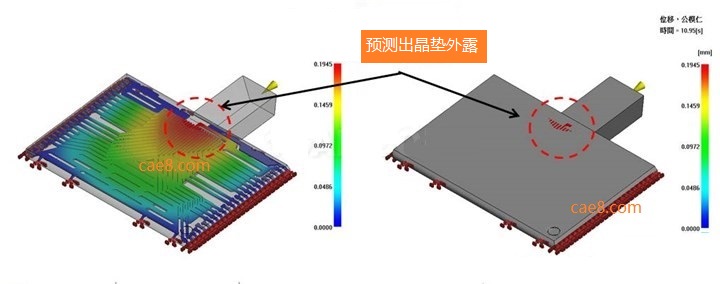

4. Predict whether the die pad shift amount is within the tolerance.

5. Predict the impact of forming conditions on the warpage deformation of the product.

6. Accurately simulate the impact of different structural designs of the product on warpage deformation.

7. Predict the impact of substrate materials on the warpage deformation of the product.

8. Optimize the forming conditions and filling patterns of thermosetting materials.

9. Predict the injection pressure and clamping force requirements.

10. Predict the positions of air holes and gold wires.

Application Cases (Moldflow Software IC Chip Packaging Mold Flow Analysis):

Introduction to the IC Chip Packaging Molding Process:

During the filling process of thermosetting epoxy resin materials in the plastic packaging process of IC components, high-viscosity molten glue and rapid flow may cause the problem of gold wire shift. Gold wire short circuit problems may occur due to gold wire shift. During the molding process, when gold wires are deformed or in contact with other gold wires, short circuit problems may occur.

The factors affecting packaging defects and failures are diverse, and material composition and properties, packaging design, environmental conditions, and process parameters all have an impact. Determine the influencing factors and the basic prerequisites for preventing packaging defects and failures. Influencing factors can be determined through experimental or simulation methods. Generally, the physical model method and the numerical parameter method are often used. For more complex defects and failure mechanisms, the trial-and-error method is often used to determine the key influencing factors, but this method requires a long test time and equipment modification, with low efficiency and high cost.

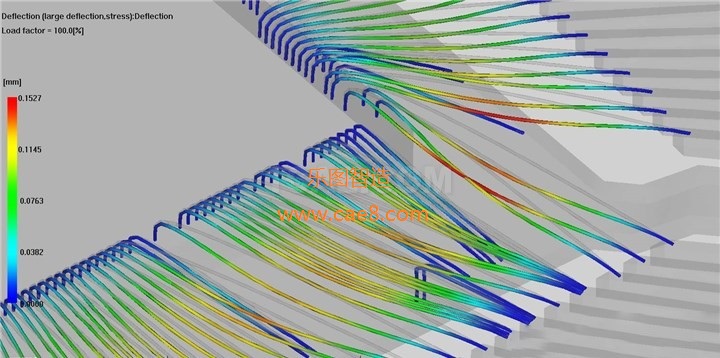

IC Chip Packaging Mold Flow Simulation —— Analysis of Gold Wire Shift Amount

1. The result is shown in the above figure: By simulating the injection filling process through Moldflow mold flow analysis software, it can be intuitively found that the gold wires have shifted and deformed, and interference has occurred between the gold wires. This is a serious problem that cannot be accepted in the requirements of the IC chip packaging molding process.

2. In addition, Moldex3D software also has the same function of analyzing the gold wire shift amount, which can provide gold wire shift prediction and the gold wire shift amount, helping users decide whether the parameter settings of the manufacturing process, the selection of materials, and the design of the lead frame are appropriate.

3. There is a certain rule that the smaller the diameter of the gold wire, the greater the degree of gold wire shift. The closer the gold wire is to the gate position, the greater the degree of gold wire shift. The greater the injection holding pressure, the more serious the shift. Therefore, this places high demands on parameter settings, material selection, and lead frame design.

4. The influencing factors include packaging design, lead layout, lead material and size, molding compound properties, wire bonding process, and packaging process, etc. The lead parameters affecting lead bending include lead diameter, lead length, lead breaking load, lead density, and so on.

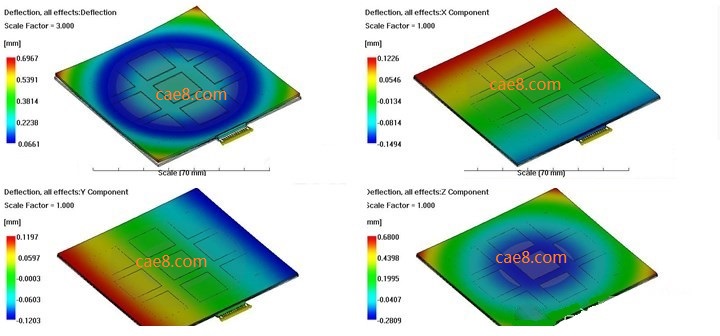

IC Chip Packaging Mold Flow Analysis Simulation —— Overall Warpage Deformation (Warpage) of Packaging Substrate

1. Warpage refers to the bending and deformation of packaged devices outside the plane. Warpage caused by the plastic packaging process can lead to a series of reliability problems such as delamination and chip cracking. Warpage can also lead to a series of manufacturing problems. For example, in plastic ball grid array (PBGA) devices, warpage can lead to poor coplanarity of solder balls, causing mounting problems during the reflow soldering process when the device is assembled onto a printed circuit board.

2. The factors affecting the shift include the fluidity of the molding compound, the assembly design of the lead frame, and the material properties of the molding compound and the lead frame. Packaging devices such as thin small-outline package (TSOP) and thin quad flat package (TQFP) are prone to base shift and pin deformation due to the thin lead frame.

IC Chip Packaging Mold Flow Analysis Simulation —— Analysis of Die Pad Shift and Exposure during the Injection Molding Process,

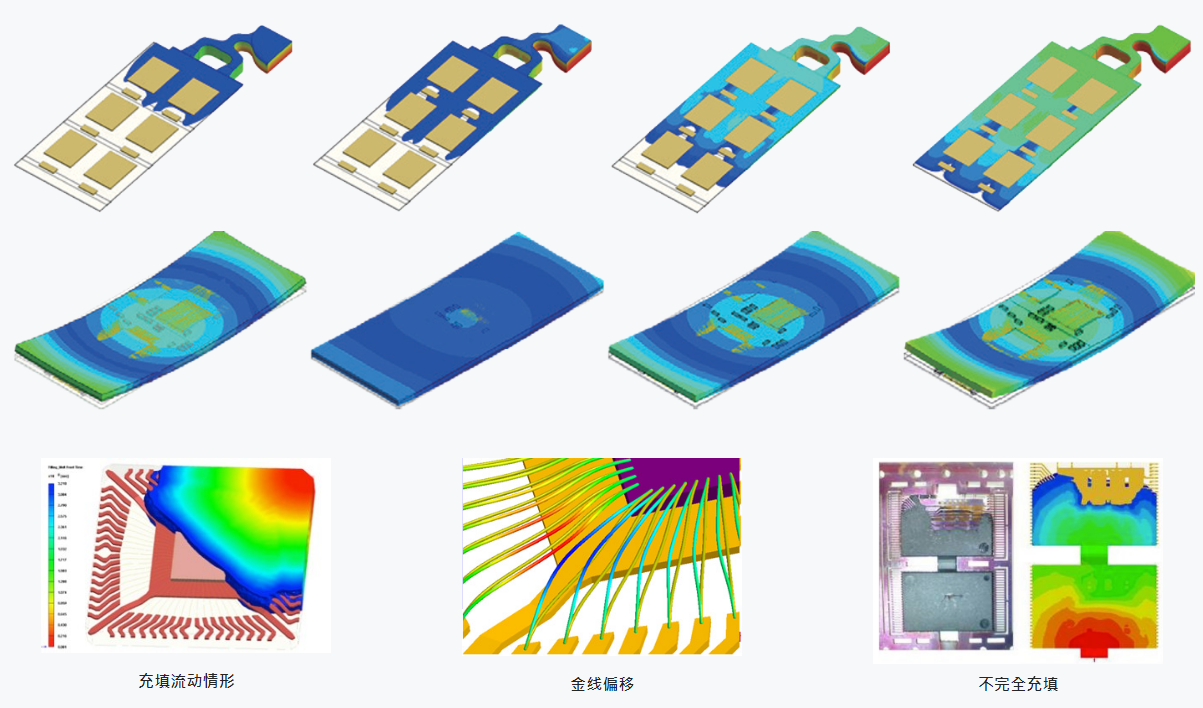

Mold Flow Analysis and Simulation of IC Chip Packaging —— Analysis of Trapped Gas Conditions in the Packaging and Injection Molding Process

1. The filling simulation analysis believes that it is the contact between the bottom melt front and the chip that leads to the obstruction of fluidity. Part of the melt front flows upward and fills the top of the half mold through the large opening area around the chip. The newly formed melt front and the adsorbed melt front enter the top area of the half mold, thus forming bubbles.

2. In the packaging process, bubbles are embedded in the epoxy material to form voids. Voids can occur at any stage in the packaging process, including transfer molding, filling, potting, and printing of plastic encapsulation materials in an air environment. Voids can be reduced by minimizing the amount of air, such as evacuation or vacuuming. It has been reported that the vacuum pressure range adopted is 1 - 300 Torr (one standard atmosphere is 760 Torr).

3. Electronic devices are a very complex system, and the defects and failures in their packaging process are also very complex. Therefore, to study packaging defects and failures, a systematic understanding of the packaging process is required so that the causes of defects can be analyzed from multiple perspectives.

Moldex3D Software Chip Packaging Module

The chip packaging module currently has quite complete supported analysis items. Besides the basic simulation of the flow filling and hardening process, it also extends to other advanced manufacturing evaluations, such as gold wire shift, chip shift, filler ratio, underfill packaging, post-curing process, stress distribution and structural deformation, etc. Through accurate simulation, major molding problems can be predicted and solved, which will help improve product quality and effectively prevent potential defects. By means of optimization, the design can be optimized, and the manufacturing cost and cycle can be reduced.

Core Advantages:

1. The genuine Moldex3D/Moldflow mold flow analysis software has accurate and reliable results.

It has the latest solution algorithms, the latest material library properties, and comprehensive result output. In the era when numerical manufacturing technology guides manufacturing, it is irresistible. By verifying the rationality of the mold design scheme and the product structure design through mold flow analysis, molding defects such as lack of materials, trapped gas, sink marks, cracking, and deformation are greatly reduced, the quality of products is improved for you, manufacturing costs are reduced, and numerical manufacturing technology enhances the market competitiveness of your enterprise.

2. Led by gold-medal consultants, having been in business for more than ten years, with rich practical experience in industry-university-research cooperation.

The gold-medal consultants are familiar with the high-precision and high-requirement standards and specifications of OEMs such as SAIC, BAIC, GAC, Changan, GM, BMW, and Tesla. What is provided to customers is not just a "mold flow analysis report", but powerful theoretical data that can guide production.

3. With a complete CAD/CAE/CAM product chain, it provides you with one-stop collaborative development.

From product design and analysis to mold forming design and analysis, experts in various fields can well connect each link and consider each link globally.

4. High-end servers with a capacity of hundreds of thousands can complete orders efficiently and meet the delivery requirements at all levels.

To meet the increasingly accelerated R & D cycle, the company is equipped with high-end hardware, experienced experts and the latest version of software solution software to achieve efficient operation.

5. The charging is honest and reasonable, customer-oriented, and the most suitable product solutions are formulated and recommended for each customer.

Good products are naturally expensive, but they may not be the most suitable. Customer-oriented, formulate and recommend the most suitable product solutions for each customer. Focus on integrity, prioritize quality, serve wholeheartedly, and win trust.

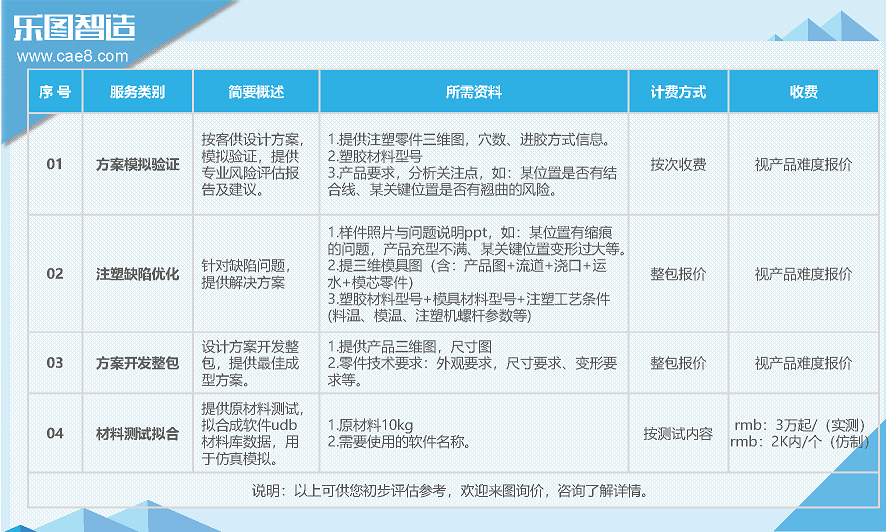

Charging Method:

Contact us for consultation, explore scientific casting schemes, and create higher added value together.

Letu Zhizao Technology is engaged in product performance optimization, finite element analysis engineering services, software sales, and provides scientific numerical information technology solutions for the manufacturing industry.

Declaration: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

View more cases: IC Chip Packaging Analysis Rubber/Silicone Mold Flow Analysis Gravity Casting Simulation Analysis Die Casting Mold Flow Analysis MAGMA Analysis and Simulation Drop Test Analysis Fatigue Analysis CFD Analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice