Silicone rubber/liquid silicone mold flow analysis

Service Contents:

Outsourcing of liquid silicone mold flow analysis in industries such as medical, automotive, and electronics, material test fitting for UDB, optimization of injection molding defects, and development of injection molding schemes.

Application Value of Liquid Silicone Mold Flow Analysis:

1. Determine the injection pressure to avoid problems such as incomplete filling, excessive injection pressure, and flash. Maximize the optimization of product and mold schemes, reduce the risk of molding defects, and reduce manufacturing costs.

2. Determine the number of cavities. For liquid silicone key products, the difficulty lies in their extremely thin wall thickness, which is only 0.3mm. If there are too many cavities, it is easy to have the problem of incomplete filling. Moreover, due to the high cost of molds with multiple cavities in one mold, in order to avoid mold development failure, it is necessary to conduct mold flow analysis in advance to verify and optimize the design scheme and eliminate potential risks to reduce development costs.

3. Verify the rationality of the mold design scheme and the product structure design through Moldflow mold flow analysis, greatly reduce injection molding defects such as lack of glue, trapped gas, shrinkage, cracking, and deformation, improve the quality of injection molded parts for you, reduce manufacturing costs, and the numerical manufacturing technology of Moldflow mold flow analysis can enhance the market competitiveness of your enterprise. The results of the genuine Moldex3D/Moldflow mold flow analysis are accurate and reliable, with the latest solution algorithms, the latest material library properties, and comprehensive result output. The era when numerical manufacturing technology guides manufacturing is irresistible.

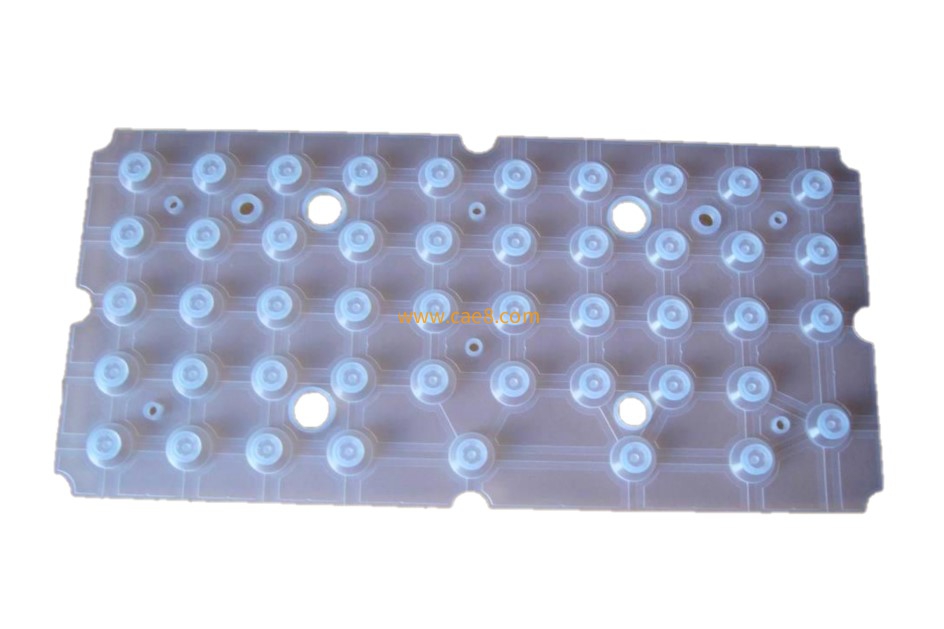

Brief Introduction of Successful Cases of Liquid Silicone Keys:

Transparent liquid silicone rubber, as the name implies, is silicone rubber in liquid form. After cross-linking and curing, it forms solid silicone rubber with certain light transmittance, which we call transparent liquid silicone rubber or transparent liquid silicone. It can be used for coating, impregnation, and pouring. This kind of rubber has good fluidity, low viscosity, and excellent physical and mechanical properties.

The main characteristics of this kind of product are excellent transparency and perfectly retaining the original dielectric insulation, stability, high and low temperature resistance, resistance to yellowing, softness, safety, environmental protection, and biocompatibility of silicone materials.

The product is only 0.3mm thick. The feasibility of multiple cavities in one mold directly affects the success or failure of mold opening. The cost of its mold is relatively high. Therefore, in order to avoid mold development failure, it is necessary to conduct mold flow analysis in advance to verify and optimize the design scheme and eliminate potential risks to reduce development costs.

Characteristics of Liquid Silicone:

1. Excellent demolding performance.

2. It can be heated to accelerate curing if necessary.

3. Its translucent appearance allows for precise cutting from the block mold along the dividing line.

4. Extremely low shrinkage rate and good dimensional stability.

5. Medium to high hardness (40 Shore A), but with elasticity and toughness.

6. It can be used in high-temperature casting applications.

Application Areas of Liquid Silicone Products:

1. Encapsulation and protective adhesives for transparent materials required by medical devices, LED electronic products, display screens, optical devices, etc.

2. As an environmental isolation potting adhesive, it can relieve stress for products such as sensors, thyristors, IGBTs, semiconductor rectifier devices, and precision electronic modules, avoid short circuits between charged bodies of electronic components, and play a certain sealing and protective role.

3. Transparent liquid silicone rubber, because it is in liquid form and can automatically undergo an addition curing reaction after mixing and has certain hydrophobic properties, is used in some high-end umbrella fabrics. Coating transparent liquid silicone rubber on the outer layer of the umbrella fabric forms a hydrophobic protective layer, and the treated umbrella fabric has certain hydrophobicity and can resist certain ultraviolet hazards.

3. Transparent liquid silicone rubber, due to its liquid form, can automatically undergo an addition curing reaction after mixing and has certain hydrophobic properties. It is used in some high-end umbrella fabrics. By coating transparent liquid silicone rubber on the outer layer of the umbrella fabric, a hydrophobic protective layer is formed. The treated umbrella fabric has certain hydrophobicity and can resist certain ultraviolet hazards.

Core Advantages:

1. The genuine Moldex3D/Moldflow mold flow analysis software has accurate and reliable results.

It has the latest solution algorithms, the latest material library properties, and comprehensive result output. In the era when numerical manufacturing technology guides manufacturing, it is irresistible. By verifying the rationality of the mold design scheme and the product structure design through mold flow analysis, molding defects such as lack of materials, trapped gas, sink marks, cracking, and deformation are greatly reduced, the quality of products is improved for you, manufacturing costs are reduced, and numerical manufacturing technology enhances the market competitiveness of your enterprise.

2. Having been in business for more than ten years, led by gold-medal consultants, with rich practical experience in industry-university-research cooperation.

Familiar with the high-precision and high-requirement standards and specifications of OEMs such as SAIC, BAIC, GAC, Changan, GM, BMW, and Tesla. What is provided to customers is not just a "mold flow analysis report", but powerful theoretical data that can guide production.

3. With a complete CAD/CAE/CAM product chain, it provides you with one-stop collaborative development.

From product design and analysis to mold forming design and analysis, experts in various fields can well connect each link and consider each link globally.

4. High-end servers with a capacity of hundreds of thousands can complete orders efficiently and meet the delivery requirements at all levels.

To meet the increasingly accelerated R & D cycle, the company is equipped with high-end hardware, experienced experts and the latest version of software solution software to achieve efficient operation.

5. The charging is honest and reasonable, customer-oriented, and the most suitable product solutions are formulated and recommended for each customer.

Good products are naturally expensive, but they may not be the most suitable. Customer-oriented, formulate and recommend the most suitable product solutions for each customer. Focus on integrity, prioritize quality, serve wholeheartedly, and win trust.

Charging Method:

Contact us for consultation, explore scientific manufacturing solutions, and create higher added value together.

Letu Zhizao Technology is engaged in manufacturing solution development, finite element analysis engineering services, software sales, and provides scientific numerical information technology solutions for the manufacturing industry.

Declaration: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

View more cases: Finite Element Simulation IC Chip Packaging Analysis Rubber/Silicone Mold Flow Analysis Gravity Casting Simulation Analysis Die Casting Mold Flow Analysis MAGMA Analysis and Simulation Drop Test Analysis Fatigue Analysis CFD Analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice