Mold flow analysis of stator windings of plastic-sealed motor, deformation analysis of iron parts

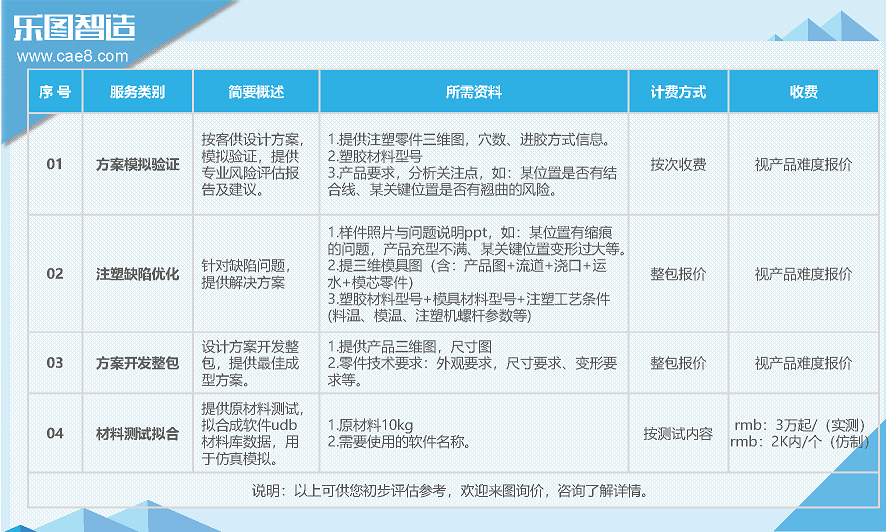

Service Contents:

Gold and silver consultants, mold flow analysis verification, optimization of molding defects, development of molding schemes, UDB material test fitting, and software sales.

Application Value of Iron Part Deformation Analysis:

1. Predict the deformation situation under the action of inserts, the offset of iron parts, etc., maximize the optimization of product and mold schemes, reduce the risk of molding defects, and reduce manufacturing costs.

2. It can predict the shrinkage of products in advance, whether they can be filled fully, and whether the dimensions such as flatness and roundness are within the control range. Since iron parts affect the shrinkage of plastics, it is easy to have dimensional errors if estimated according to the conventional shrinkage rate.

3. Clarify the number and position of hot runners. The needle valve hot runner is expensive. Try to reduce the number of needle valve hot runners on the premise of meeting the molding requirements, which is beneficial to reducing the cost.

4. Verify the rationality of product structure design through Moldflow mold flow analysis, greatly reduce injection molding defects such as lack of glue, trapped gas, shrinkage, cracking, and deformation, improve the quality of injection molded parts for you, reduce manufacturing costs, and enhance the market competitiveness of your enterprise. The results of the genuine Moldex3D/Moldflow mold flow analysis are accurate and reliable, with the latest solution algorithms, the latest material library properties, and comprehensive result output. The era when numerical manufacturing technology guides manufacturing is irresistible.

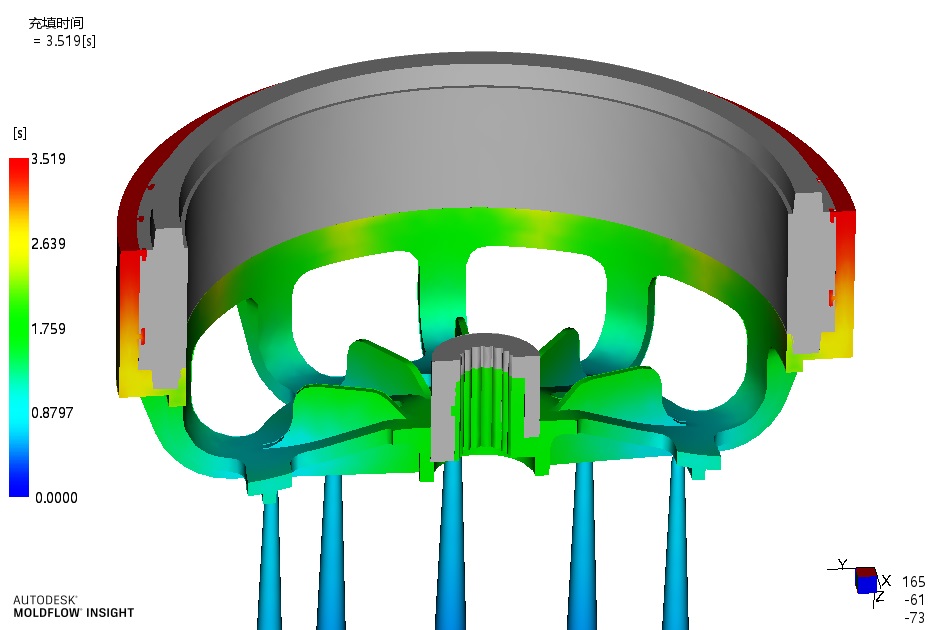

Application Cases:Mold flow analysis of the encapsulation mold for the stator winding of the plastic-encapsulated motor

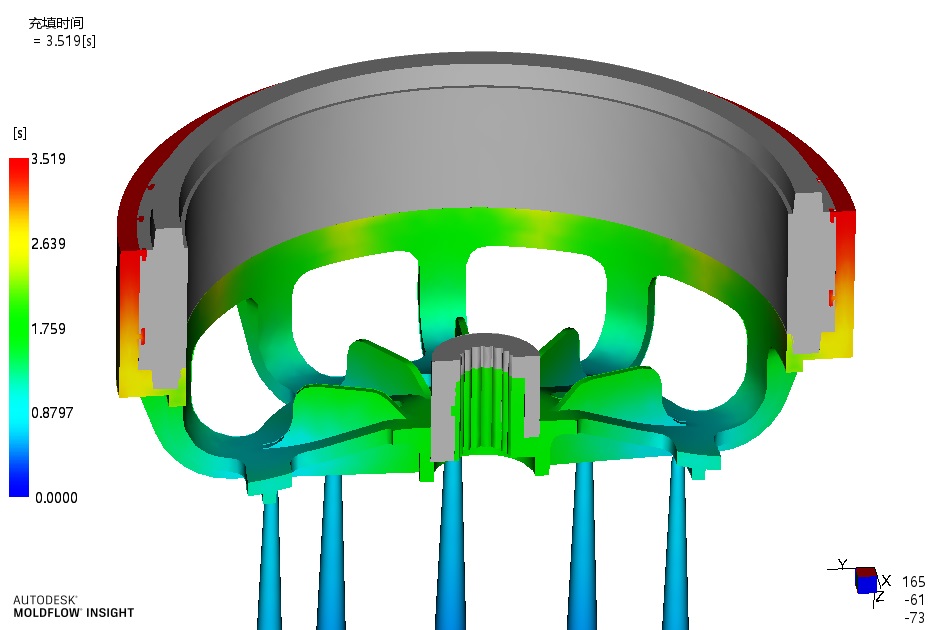

Highlights: The iron part deformation analysis includes the overall real deformation of the insert. The encapsulation mold flow analysis shows that the plastic shrinkage is affected by the insert, and only the coupled simulation can obtain the real deformation state.

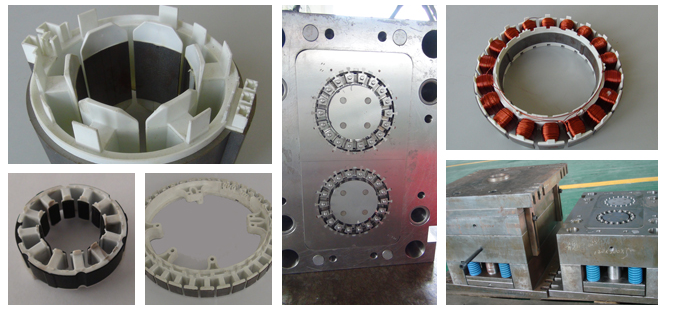

This is the stator winding of the plastic-encapsulated motor produced by our company in 2010. It adopts the integrated injection molding of the whole circular iron core and uses Moldflow software for simulation analysis. It is a typical engineering case of mold flow analysis for iron-encapsulated parts. For the stator winding of the plastic-encapsulated motor, the injection molding process is adopted. The metal iron parts are fixed in the mold, and then the plastic is injected to form an integral whole with the iron parts.

There are usually 5 - 6 different structural design schemes for the injection molds of this kind of products. It is very challenging to try each design form.

Functions:

1. From the deformation results of the mold flow analysis, the overall deformation process and values can be clearly seen. The final deformation of the product can be predicted in advance, and whether the dimensions such as flatness and roundness are within the control range. Since iron parts affect the shrinkage of plastics, it is easy to have dimensional errors if estimated according to the conventional shrinkage rate.

2. Clarify the number and position of hot runners. The needle valve hot runner is expensive. Try to reduce the number of needle valve hot runners on the premise of meeting the molding requirements, which is beneficial to reducing the cost.

The left picture shows the assembly status of plastic parts and iron parts. The green area is the plastic part, and the brown is the metal part. The right picture shows the cross-section view of the filling time, including iron parts, so that the influencing factors of metal iron parts can be considered.

This kind of product is prone to incomplete filling. The reason is that the local wall thickness is relatively thin, and the heat conduction and heat dissipation ability of iron parts is relatively strong, resulting in a large heat loss during plastic filling. This greatly tests the feasibility of the gate design scheme.

Charging Standards:

Contact us for consultation, explore scientific casting schemes, and create higher added value together.

Letu Zhizao Technology, product performance optimization, finite element analysis engineering services, software sales, provides scientific numerical information technology solutions for the manufacturing industry.

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice