Mold flow analysis udb material library, material testing, udb fitting

Business Introduction:

Import PVT and other testing equipment+Professional mold flow analysis consultant fitting=Obtain accurate and reliable UDB material files.

Conduct material tests according to the testing methods of mold flow analysis software and write UDB data files as required. Reliable material testing, mold flow analysis UDB material library testing, and MTR material library testing and fitting services. 199 4191 2022

Which Materials' UDB Can Be Tested:

It can provide thermoplastic and thermosetting material testing and corresponding mold flow analysis UDB material data fitting, such as PVT, viscosity, specific volume, specific heat, Young's modulus, Poisson's ratio, crystallinity, viscoelasticity, D3, heat conduction, stress-strain curve, creep curve, etc.

Material UDB Fitting Test Items:

It has a full set of mold flow analysis UDB data testing and analysis capabilities, and can obtain material characteristic parameters such as stress-strain curves, tensile modulus, Poisson's ratio, PVT, CLTE, specific heat, thermal conductivity, viscosity, and related analysis UDB files, etc.

a. Thermoplastic Material Testing

Shear viscosity, specific heat capacity, thermal conductivity, density, transition temperature, PVT, mechanical properties, coefficient of thermal expansion, etc.

b. Thermosetting Material Testing, Rubber and Silicone LSR Material Testing

Reaction viscosity, curing kinetics, specific heat capacity, thermal conductivity, density (uncured and cured), PVT (uncured and cured), mechanical properties, coefficient of thermal expansion, and fit the test data into UDB files.

Why Seek a Mold Flow Analysis Company to Fit the UDB Material Library?

1.Data fitting is highly professional and very important (Having equipment doesn't mean having the ability to conduct UDB tests).

The software has its own testing standards and writing formats. Having equipment doesn't necessarily mean being able to measure the data required by the software. The originally measured data cannot be directly used for software analysis and needs to be converted and processed according to the software writing rules, and then fitted into a curve equation using professional fitting software, which requires a professional theoretical knowledge background and rich experience.

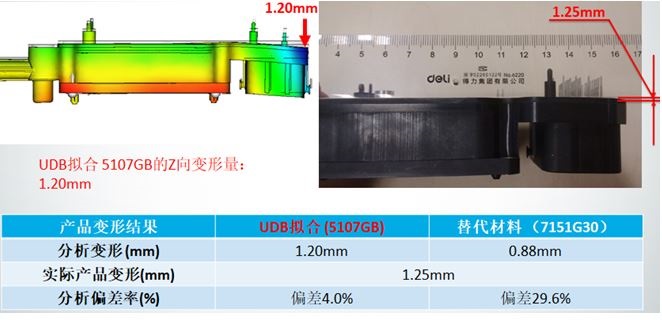

2. Whether the material UDB data is accurate or not can make a huge difference in the mold flow analysis results.

Materials from different manufacturers or with different grades, even of the same type, can show completely different results during the molding process, such as pressure, shrinkage, deformation, etc. Therefore, it is particularly necessary to conduct accurate material testing and fitting.

Once a test comparison was done. Compared with the actual deformation, the deviation of the results analyzed by the actually measured and fitted UDB materials was 4%, while the deviation of the results analyzed by the substitute materials was 29.6%. So the accuracy of the results of the actually measured and fitted UDB materials is much higher.

Testing Equipment Display:

Capillary rheometer, PVT measuring instrument, universal testing machine, differential scanning calorimeter, thermomechanical analyzer

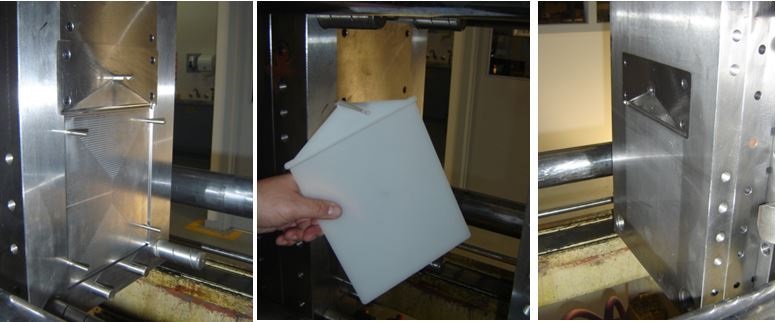

Custom Sample Molds:

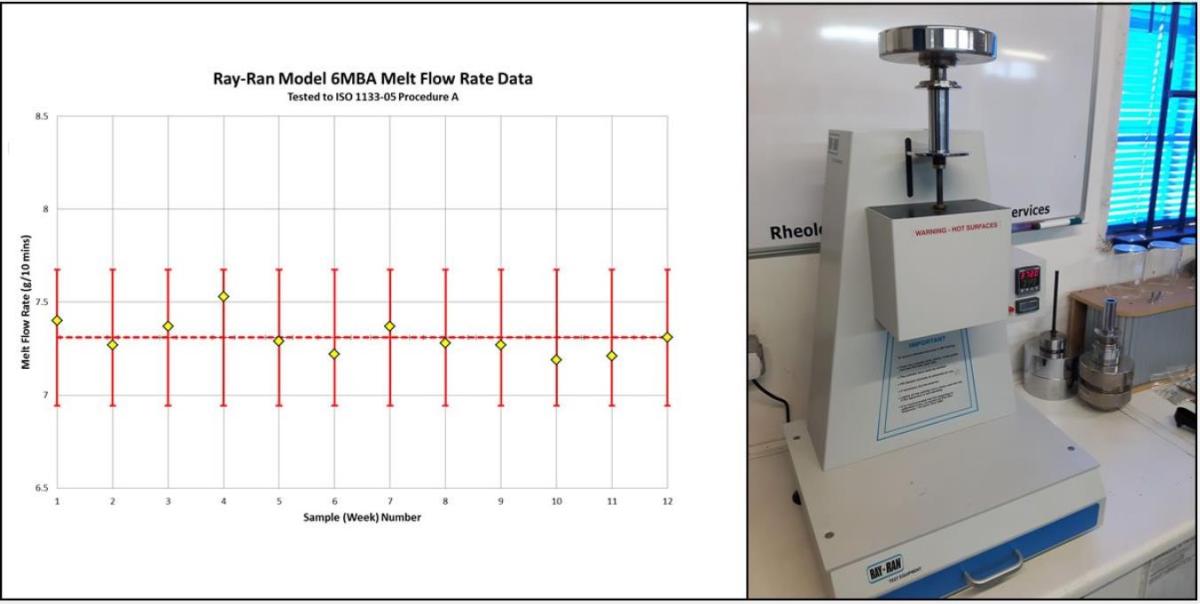

Melt Flow Rate (MFR) Test

Melt flow index (MFI), or later called melt flow rate (MFR), is one of the widely used rheological quality control tools in the plastics industry. There are various shapes and configurations of testing instruments, but the basic form is the capillary rheometer. The MFI value quoted for a specific material is the average weight of the "cut-off" of the material collected at set time intervals under isothermal and constant load extrusion. This instrument is also used to determine the melt volume rate (MVR), which is the time required for a known volume of material to be extruded through a mold under a given load and temperature. We use the Ray-Ran Model 6MBA melt flow rate instrument to provide measurements according to the MFR of ISO standard 1133 procedure A (ASTM D1238 procedure A) and the MVR of ISO standard 1133 procedure B (ASTM D1238 procedure B).

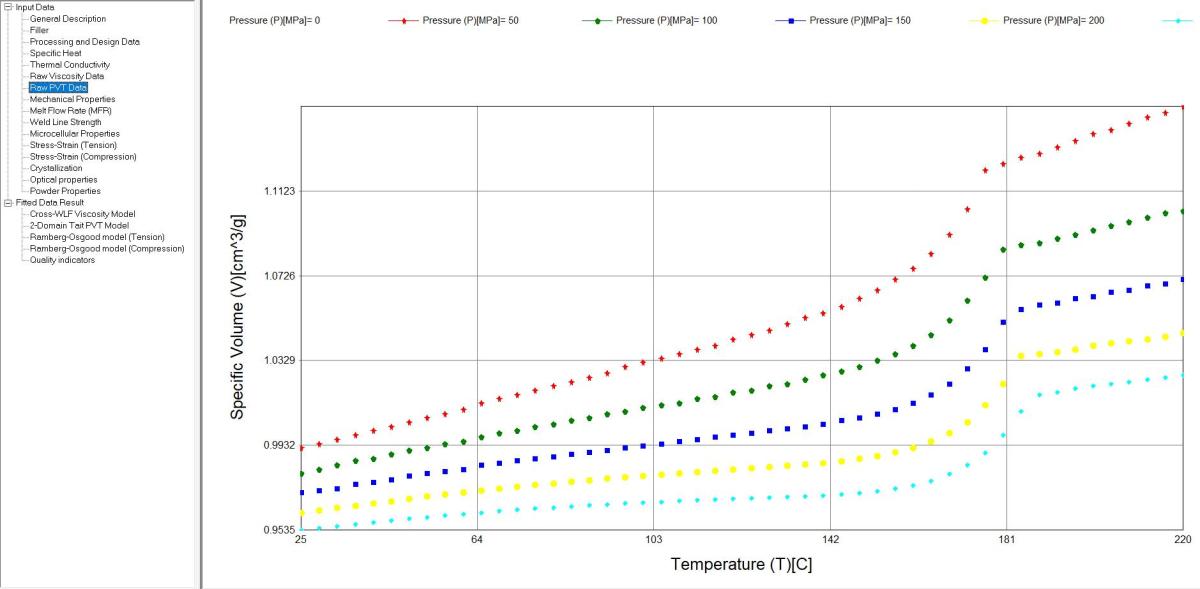

PvT (Pressure, Volume, Temperature) Test

Use the PvT equipment of Rapra Technology to measure PvT data (pressure, volume, temperature). The PvT data describes how the specific volume of the material changes with pressure and temperature. The specific volume will change significantly under the high temperature and high pressure encountered in processes such as polymer injection molding and is a major factor in the holding and cooling stages of the molding cycle. PvT information is crucial for flow simulation software to accurately predict shrinkage and warpage. The PvT behavior is measured using a high-pressure indirect expansion measurement system. This technology uses a stainless steel bellows test cell with mercury as the containing fluid. The volume changes related to temperature and pressure changes are monitored by a displacement sensor, and samples containing fluid can be characterized in solid and liquid forms. The test cell is surrounded by high-temperature oil in a sealed pressure vessel. Measurements can be made within a range of temperatures (23 °C to 420 °C) and pressures (5 MPa to 200MPa). The family of curves obtained from the tests is fitted into a mathematical model to provide the coefficients required by the mold flow analysis software Moldflow.

Which Mold Flow Analysis Software Are Applicable:

Mainly provide mold flow analysis material UDB fitting and MTR material library for Autodesk Moldflow software, Moldex3D software, and Sigmasoft3D software. These software have high accuracy, but if there is no accurate material data UDB, their results will be very different.

Common Questions about the UDB Material Library:

What is a UDB file? What does UDB mean? What is a plastic's UDB file? What does mold flow analysis UDB mean?

Answer: UDB is a file format of Moldflow software. It is a repository file for recording material physical property information. The Moldflow software can read the information in the UDB file. It is a storage file for obtaining material physical property information and is used for mold flow analysis solution calculation.

How to interpret the material UDB file?

Answer: The material UDB file mainly contains information such as rheological properties, thermal properties, PVT properties, mechanical properties, shrinkage properties, and filler properties.

How to open a UDB file?

Answer: The UDB file needs to be opened with Moldflow software to view the information in the UDB file.

Contact for Consultation, Explore Scientific Manufacturing Schemes, and Create Higher Added Value Together

Letu Zhizao Technology, Mold Flow Analysis Service on Behalf of Clients, Molding Defect Optimization, Software Sales, Providing Scientific Numerical Information Technology Solutions for the Manufacturing Industry.

Declaration: This article is originally from the official website of Letu Zhizao. Please indicate the source when reprinting.

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice