Structural fatigue analysis, fatigue durability analysis, fatigue life analysis

Business Scope:

Fatigue life analysis and simulation services in various fields such as fatigue analysis of mechanical heavy industry structures fatigue analysis, fatigue durability analysis in the vehicle industry, and fatigue analysis of industrial equipment..

Application Cases of Fatigue Analysis:

1. Development of Vehicle Fatigue Durability Performance

Automobile fatigue durability analysis is a set of tests to assess the reliability of the whole vehicle, systems, subsystems and components. Fatigue life analysis is the focus of durability test assessment and also a key factor in determining the quality of automobiles. More than 90% of automobile component damages belong to fatigue damages.

The above figure shows the traditional bench test. The traditional way of developing automobile fatigue performance is to conduct reliability test verification after the prototype is manufactured, and then make design modifications for the discovered problems. It is a repetitive process of retesting and modifying again, which has problems such as time lag, long development cycle and large capital investment.

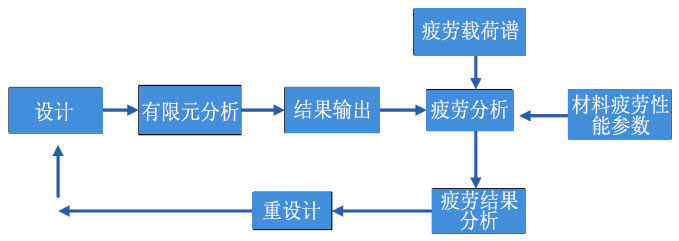

Thoughts on Fatigue Simulation Analysis Based on Finite Element

When using finite element analysis for fatigue analysis, the basic idea is as follows: Firstly, conduct static or dynamic strength analysis, and then enter the post-processor to extract relevant stress and strain results. Then define load events in the post-processor, cycle the material properties, and then calculate the life of each load event according to the required fatigue criteria. Finally, judge whether to start damage according to the cumulative damage theory.

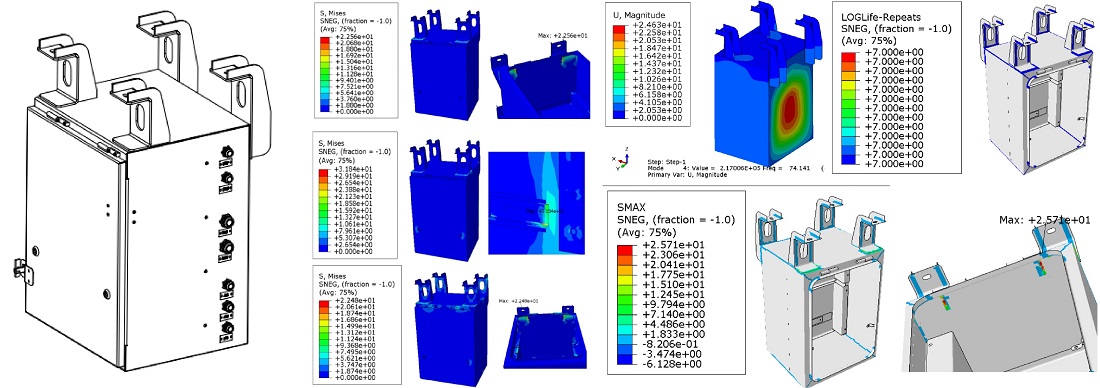

2. Life Prediction of Power Distribution Boxes for Train Hanging Equipment

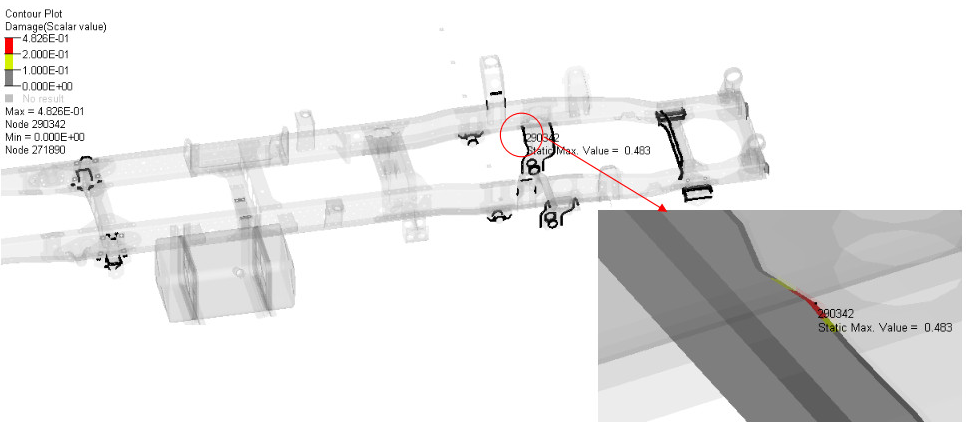

Contour Map of Fatigue Life Analysis of Chassis Components

Conduct fatigue life simulation analysis on these components and the whole vehicle based on the dynamic time-domain loads of the components and the whole vehicle to determine whether they meet the formulated fatigue durability target requirements. If not, optimization design is needed until the analysis results meet the requirements.

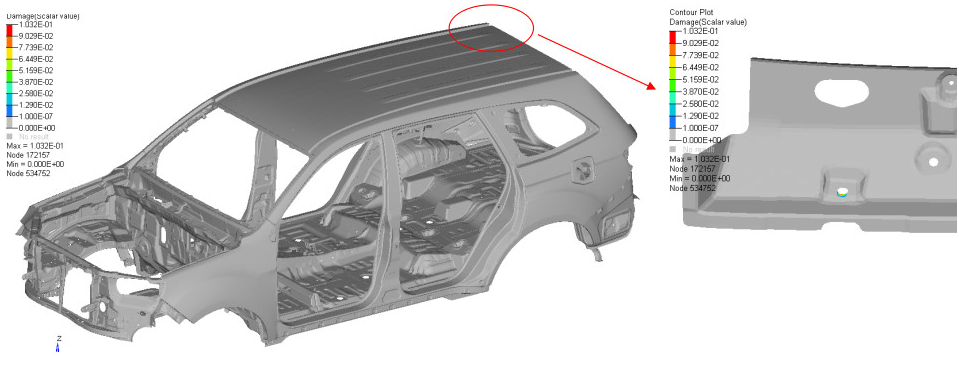

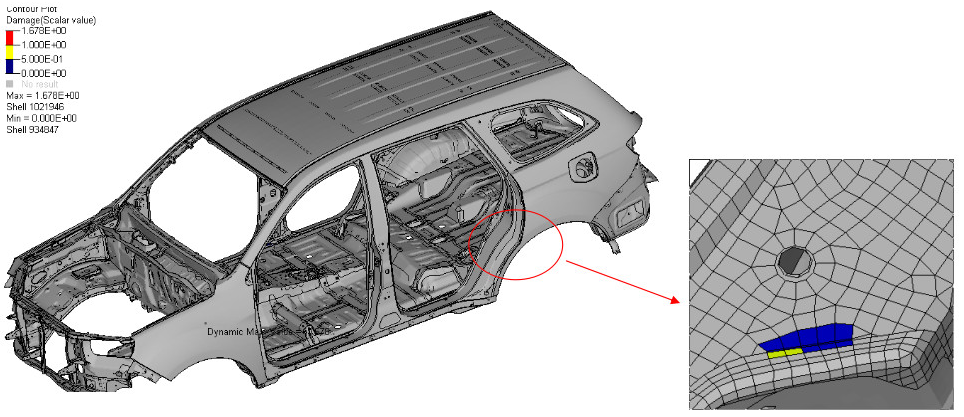

Damage Contour Map of Body Fatigue Analysis

From the damage contour map of the body in white, the maximum damage value of the body in white is 0.103 (equivalent life of 29,000 kilometers), which exceeds the target value. The position of the maximum damage is at the hole on the lower plate of the seventh crossbeam on the top, and the damages of other parts are all less than the target value.

Damage Contour Map of Body Weld Fatigue Analysis

The maximum damage value of the welds of the body in white is 1.678, which exceeds the target value. The damage values in the yellow area are greater than 0.5 and less than 1, and the damage values in the red area are greater than 1.

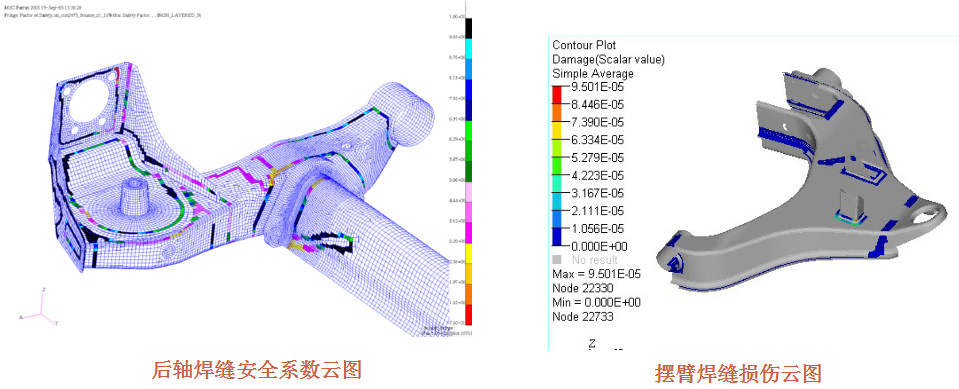

Fatigue Life Analysis of Chassis

Fatigue Analysis of Chassis Welds

Fatigue Analysis of Frame Welds

As shown in the figure, there is relatively large damage at the welding position of the engine bracket, while the damage at other parts is less than 0.1.

By applying the finite element analysis technology, fatigue analysis engineers carried out 20 rounds of optimization calculations for the scheme, which lasted for as long as 200 hours. Eventually, on the premise that the fatigue performance met the requirements of the set goals, the durability was improved by about 50%. After bench tests and real vehicle road tests for verification, there was no fatigue cracking problem, and the durability was greatly improved, which verified the accuracy of the simulation analysis.

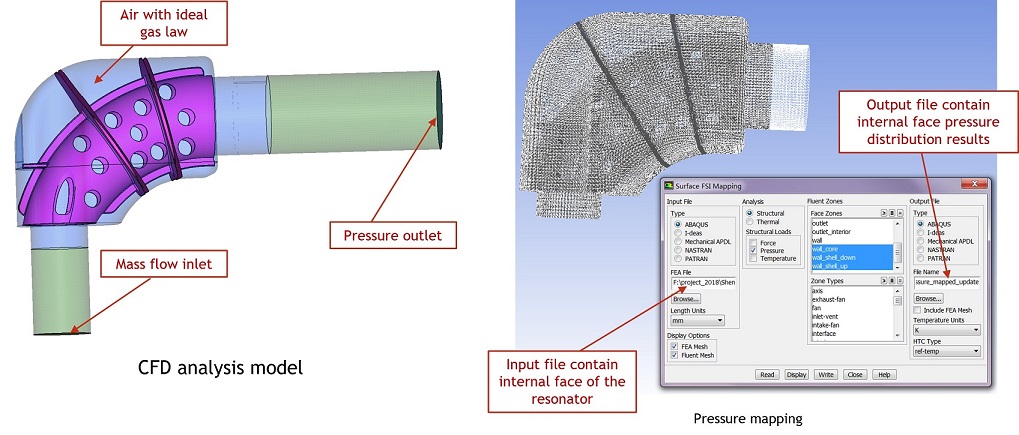

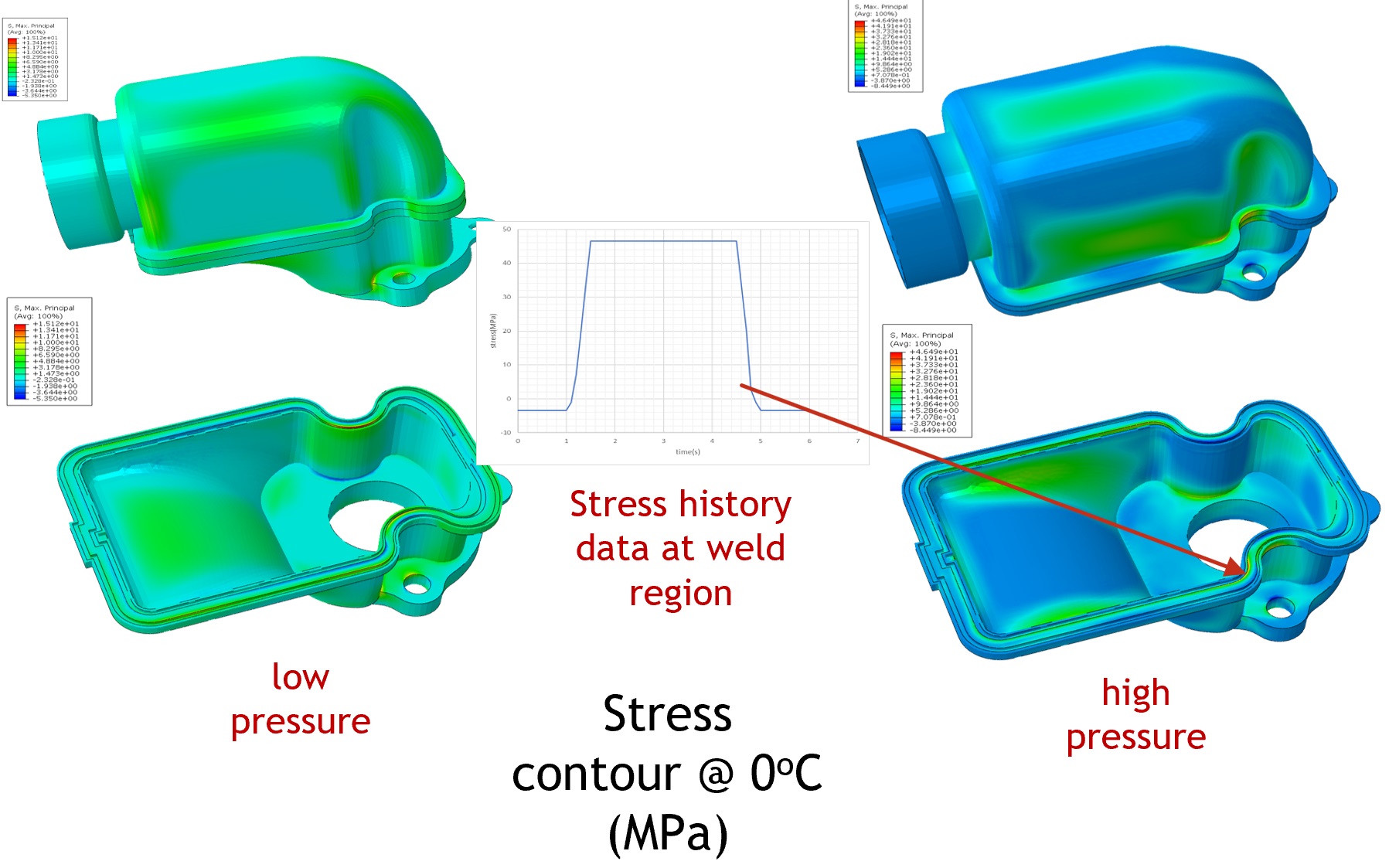

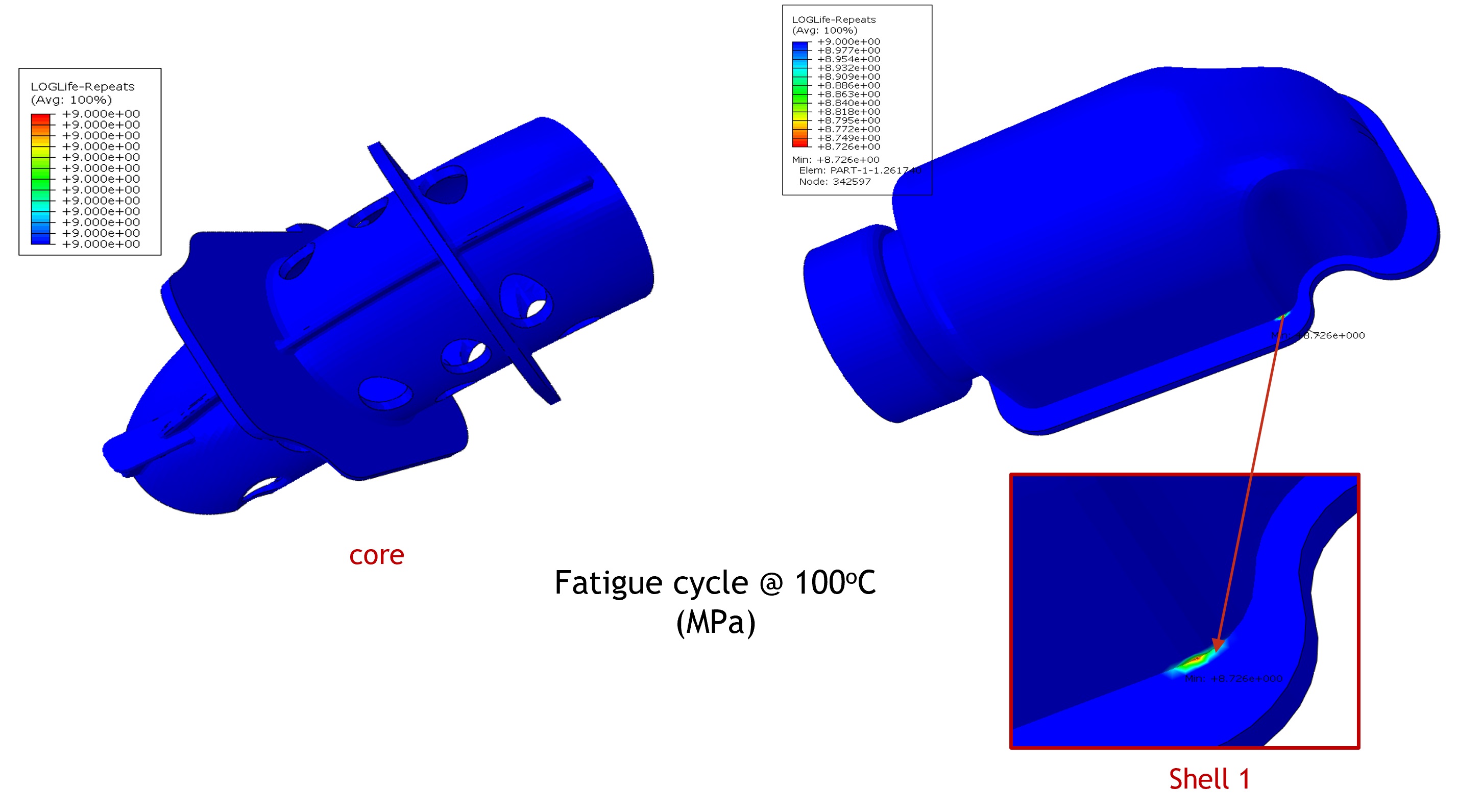

2. Implementing Pressure Pulsation Fatigue Analysis Based on Fluent + ABAQUS + FE-SAFE

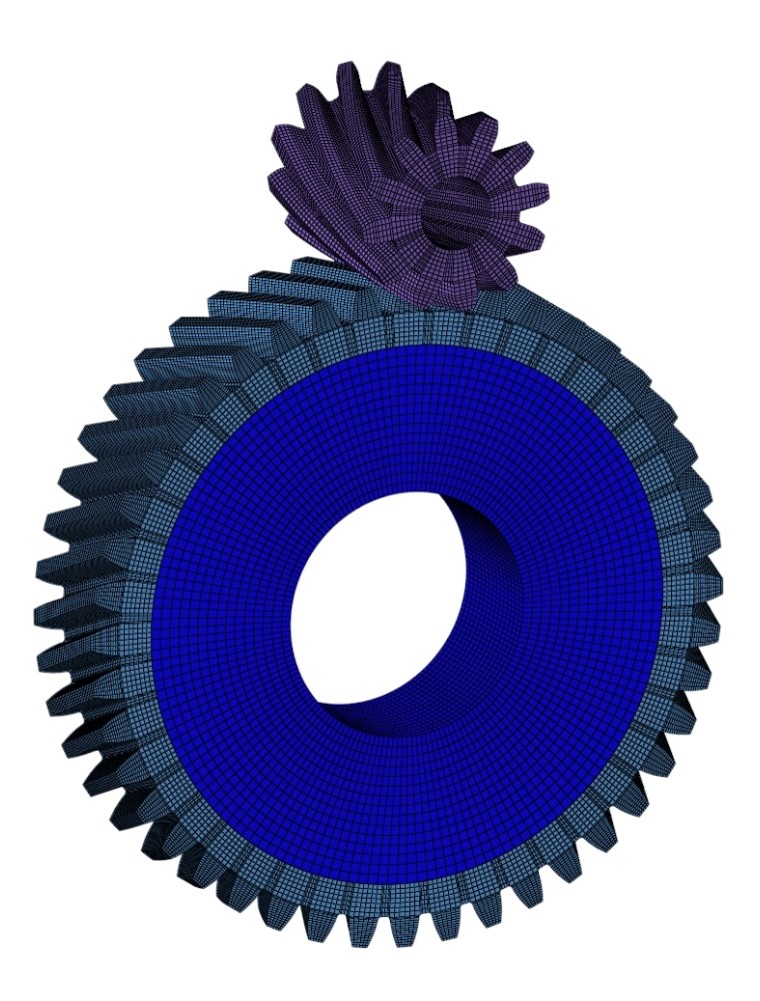

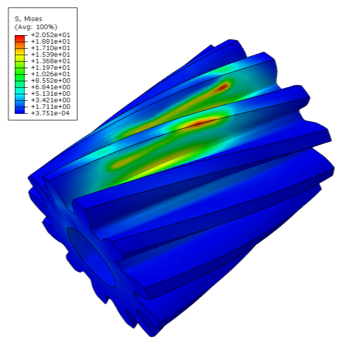

3. Implementing Gear Fatigue Durability Analysis Based on FE-SAFE + ABAQUS

During the gear meshing process, the tooth surface is prone to surface fatigue wear. Based on the maximum shear stress theory of fatigue wear, the maximum shear stress is generated near the contact surface. If the maximum shear stress exceeds the yield stress of the material, plastic strain will occur. With the repeated action of the external load, cracks will appear at the place where plastic strain occurs. Therefore, when the shear stress is lower than the yield stress, surface fatigue wear is less likely to occur.

Types of Fatigue Analysis

Stress fatigue simulation (uniaxial/multiaxial fatigue, principal stress fatigue, Von Mises stress fatigue, BS7608 weld fatigue, Dang Van infinite life fatigue)

Strain fatigue simulation (uniaxial/multiaxial fatigue, maximum principal strain fatigue, maximum shear strain fatigue, Brown-Miller combined strain fatigue, cast iron fatigue)

Information Required for Quotation

1. Three-dimensional model drawings (UG, Solidworks, Pro/E, CATIA, or step formats are all acceptable). A confidentiality agreement can be signed. If it's inconvenient to send the drawings, pictures of relevant test parts are also acceptable. Our company will fulfill strict confidentiality obligations.

2. A PPT document explaining the test conditions, clearly stating the content to be tested, mainly including fixed constraint conditions, assembly connection methods, boundary conditions, load application methods, areas of concern in the simulation, a list of part materials, requirements for the format of the simulation report, etc.

3. Software requirements, requirements for finite element simulation technology, delivery time requirements, etc.

Declaration: This article is original from the official website of Letu Zhizao. Please indicate the source when reprinting.

View More Cases: Heat Dissipation Analysis Thermal Simulation Analysis Die Casting Mold Flow Analysis Modal Analysis CFD Analysis Electromagnetic Field Simulation Analysis Drop Analysis

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice