Simulation of Vehicle Collision Analysis

Business Scope:

We provide you with professional CAE analysis technical services such as various collision analyses, body modal analysis, fatigue durability analysis, NVH performance analysis, and CFD analysis.

Application Value of Automobile Collision Simulation:

It drives lean design and a rapid automobile development process, can save a lot of development costs and shorten the development cycle. The automobile industry is a rapidly developing industry, and its competition is becoming increasingly fierce. In this situation, the speed of launching new products is getting faster and faster. The highly competitive automobile market has put forward high requirements for the development cycle and quality performance of automobiles. An automobile is a complex product composed of thousands of parts, and a wide variety of engineering problems are often involved in the R & D process. For the development of a brand-new vehicle model, if there is no CAE analysis, the risks will be extremely high.

Application Cases of Automobile Collision Simulation:

Dongfeng Peugeot conducts collision analysis based on the LS-DYNA finite element software and combines physical verification to improve the passive safety performance of vehicles.

I. Purpose of Collision Analysis

Check the degree to which the impact kinetic energy is absorbed by the bumper and the front apron area of the vehicle body as well as the structural strength of the compartment. Use the sensor data of the dummies in the vehicle to convert them into indicators corresponding to the regulations, so as to check the degree of harm to the human body in a frontal collision and judge the collision performance of the prototype vehicle. Reduce the number of deaths of vehicle occupants and the possibility of serious injuries to people.

II. Test Regulations and Standard Requirements for Collision Analysis

2.1 Test Regulation: ECE94

Among the current government mandatory regulations, mainly Europe (ECE94) has formulated regulations regarding 40% frontal collisions.

2.2 Standard Requirements: Dummy Injury Indicators and Vehicle Body Structure Requirements

III. Display of Some Results of Finite Element Analysis

The vehicle body is the foundation of an automobile. A large amount of high-strength steel is used in the vehicle body. High-strength hot-formed parts are used in areas such as the A/B pillars and windshield pillars, with a tensile strength of up to 1800 MPa. The vehicle body structure is ingeniously designed and can effectively resist the impact durability requirements from all aspects. Besides the common frontal and side collisions in collision tests, Dongfeng Peugeot has also introduced rear collision and other items to simulate rear-end collision scenarios.

Application Case 2 of Automobile Collision Analysis Simulation: Collision analysis based on the Abaqus finite element analysis software.

Automobile collision simulation - frontal rigid collision analysis, automobile collision simulation - side collision analysis. In the early days, passive safety research was mainly carried out through a large number of tests. The same collision process was repeated to collect data. Such test methods took quite a long time. In developed countries, dozens of new cars needed to be manually built for each automobile safety performance test, consuming a great deal of manpower, material resources, and financial resources.

![]()

![]()

With the development of computer technology, the finite element analysis calculation method has been applied to automobile collision simulation. Through CAE collision simulation analysis, the safety of automobiles is verified, which greatly reduces the design cost and R & D cycle of automobiles, and obtains more accurate data for the next optimization of the automobile structure.

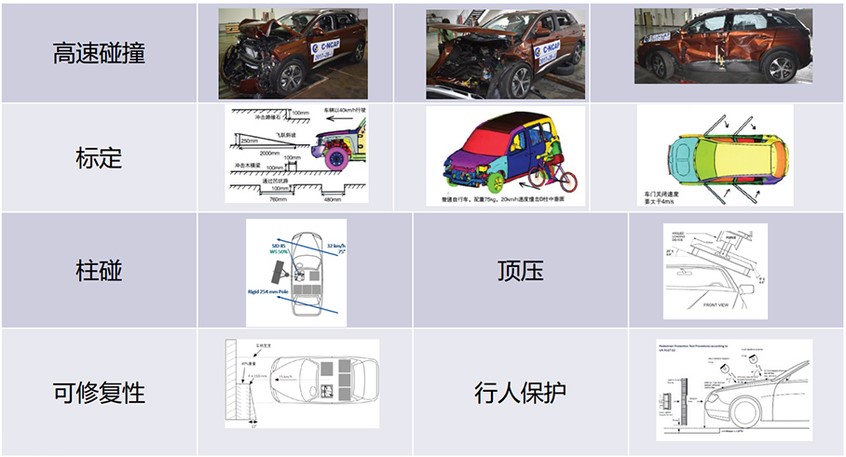

Scope of Collision Safety Performance Analysis

C-NCAP 100% frontal collision

C-NCAP 40% offset collision simulation

C-NCAP side collision analysis

Rear-end collision analysis

Pedestrian protection analysis

Performance analysis of luggage displacement and occupant protection devices

Strength analysis of seat and seat belt mounting and fixing points

Head collision inside the vehicle

Front and rear bumper collision simulation

Side door collision strength analysis

Roof crush analysis

Matching and optimization of occupant restraint systems (frontal, offset, side)

According to the purposes of collision tests, current collision tests can be roughly divided into three categories:

1. Mandatory tests required by government regulations: For example, the frontal collision tests stipulated by FMVSS208 and ECE R94 regulations, and the side collision tests stipulated by FMVSS214 and ECE R95 regulations, etc.

2. Tests to provide information for consumers: Such as the New Car Assessment Program (NCAP) implemented in countries like the United States and Europe. Automobile safety regulations stipulate that the minimum safety performance requirements stipulated by the government should be met. NCAP conducts frontal collision tests at relatively high speeds to demonstrate the collision safety performance of automobile products.

3. Collision test methods formulated by automobile manufacturers themselves: For example, they are used to propose new measures to improve the collision safety of automobiles, etc.

Charging Standards:

Quotations are calculated based on the difficulty of specific projects. Since CAE analysis covers a wide range, there are differences in collision simulation engineering and various test items, involving different types of finite element analysis and differences in their difficulty coefficients, so it is impossible to unify the prices of standard projects. Guided by customer needs, the most suitable product solutions are formulated and recommended for each customer. Integrity is emphasized, quality comes first, and services are provided with heart to win trust.

Leto Intelligent Manufacturing Technology (Suzhou) Co., LTD

199 4191 2022

Business consulting/technical consulting/exchange advice

Scan code wechat consultation, 24 hours to look forward to your voice